Hand-held suction pen free of charging

A charge-free, hand-held technology, applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of silicon wafer pollution, immobility, manual transmission of silicon wafers, etc., and achieve low production and maintenance costs, storage and Easy to carry and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

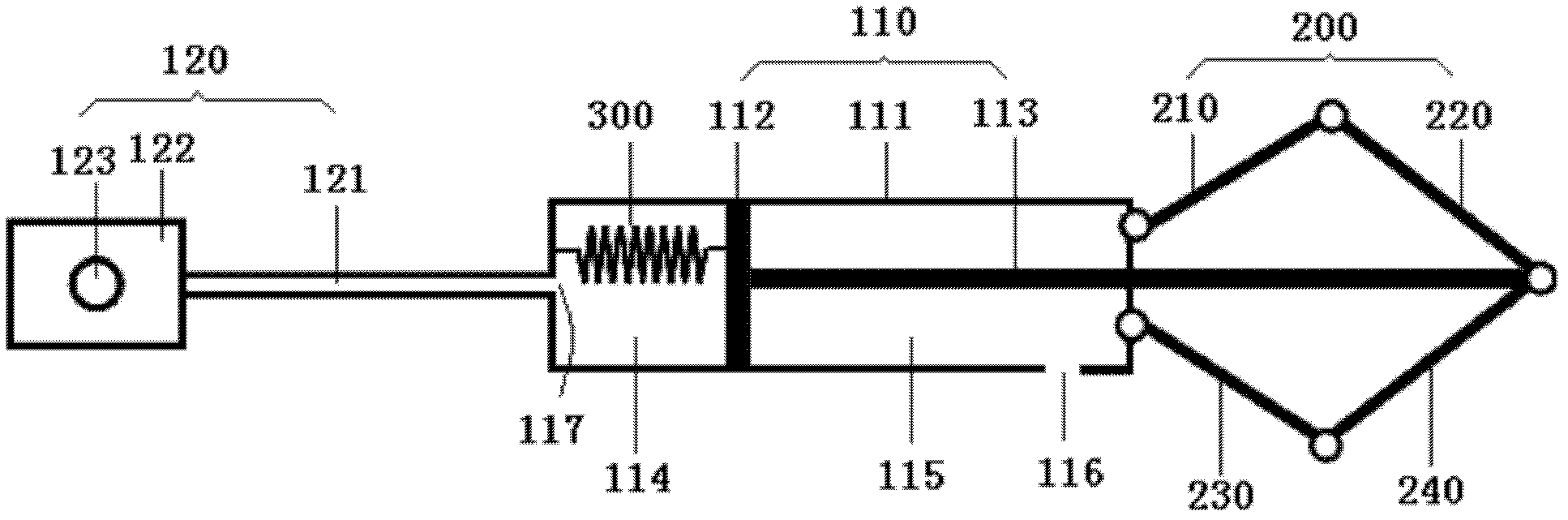

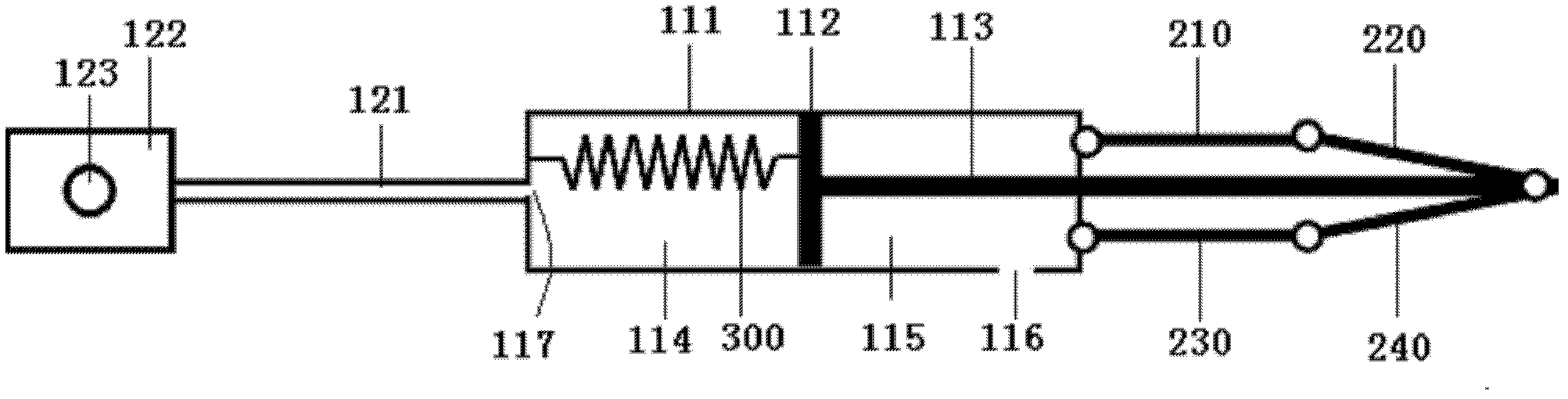

[0032] see figure 1 , the handheld charging-free suction pen of this embodiment includes a piston device 110, a suction nozzle device 120 and a handheld device 200;

[0033] The piston device 110 includes a cavity 111, a piston 112 disposed in the cavity 111 and a connecting rod 113 connected to the piston 112;

[0034] The suction nozzle device 120 is arranged at one end of the piston device 110 and is ventilated with the piston device 110;

[0035] The handheld device 200 is connected to the connecting rod 113 , and the handheld device 200 can pull the connecting rod 113 to push the piston 112 to move in the cavity 111 .

[0036] The piston 112 arranged in the cavity 111 divides the cavity 111 into two air chambers that are not connected to each other: the first air cavity 114 and the second air cavity 115, that is, due to the blocking effect of the piston 112, Gas cannot flow between the first air chamber 114 and the second air chamber 115, and the second air chamber 115 ...

Embodiment 2

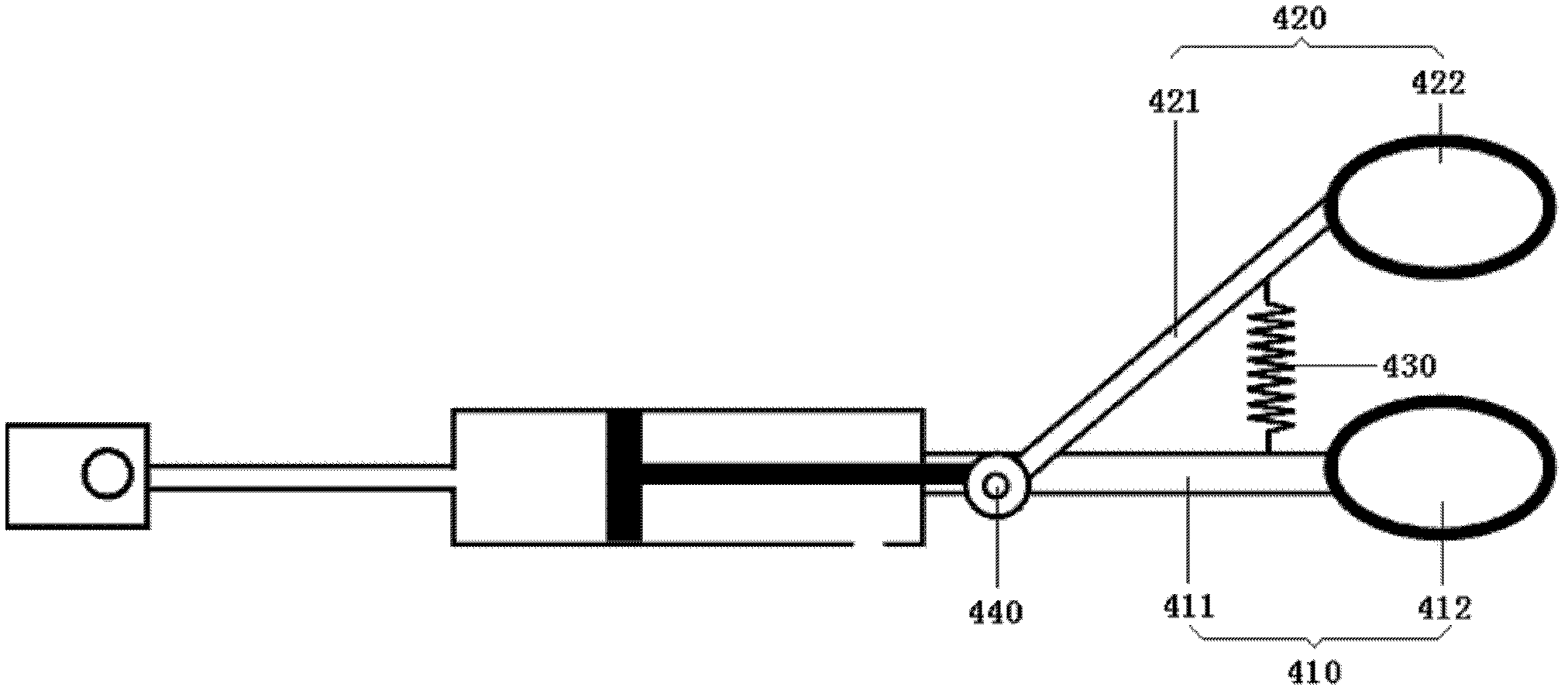

[0044] see image 3 The difference between the second embodiment and the first embodiment is that the structure of the handheld device is different, and no spring is provided in the first air cavity in the second embodiment.

[0045] In this embodiment, the handheld device includes a first handle 410, a second handle 420, a second spring 430 and a rotating device 440;

[0046] The first handle 410 is fixedly arranged at one end of the cavity;

[0047] The rotating device 440 is rotationally connected with the first handle 410, and the rotating device 440 can rotate relative to the first handle 410;

[0048] The second handle 420 is connected to the rotating device 440, and the second handle 420 can drive the rotating device 440 to rotate relative to the first handle 410;

[0049] The second spring 430 connects the first handle 410 and the second handle 420;

[0050] The connecting rod is connected with the rotating device 440, and the rotation of the rotating device 440 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com