Lithium ion battery diaphragm and high temperature thermal-stable lithium ion battery

A lithium-ion battery and diaphragm technology, which is applied in the field of lithium-ion battery diaphragms and high-temperature thermally stable lithium-ion batteries, can solve problems such as equipment cost changes and raw material cost increases, and achieve improved safety and reliability, good insulation performance, and improved high temperature The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, specific embodiments of the present invention will be described in conjunction with the accompanying drawings.

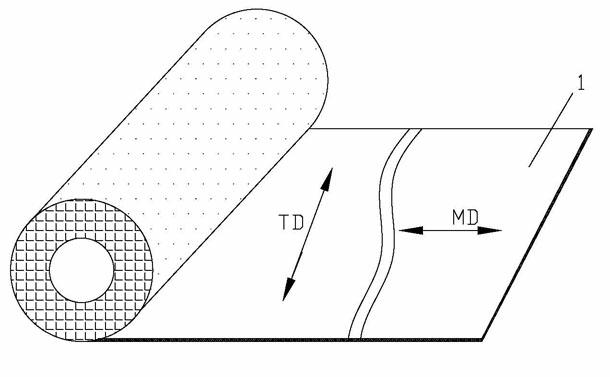

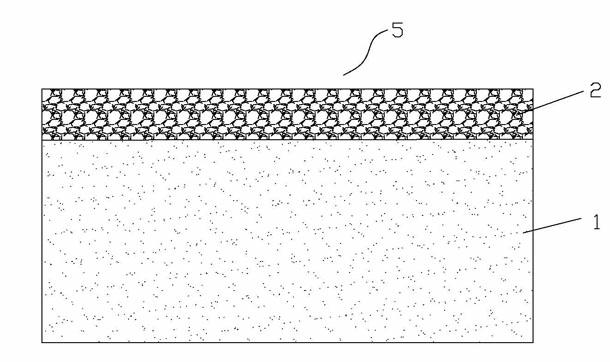

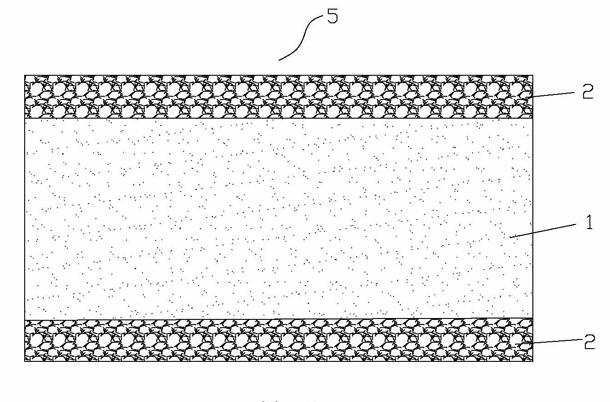

[0030] Such as Figure 1 to Figure 6 As shown, the present invention is to make a nano-ceramic material coating 2 on the surface of a conventional lithium-ion battery separator polyolefin porous film 1 . Nano-ceramic material coating 2 adopts high-temperature-resistant ceramic materials, usually: nano-scale zirconia, aluminum oxide, silicon oxide, titanium oxide, silicon nitride, boron nitride, aluminum nitride and other metal and non-metal oxides, Nitrides of metals and nonmetals. Nano-ceramic material coating 2 can be on one side of polyolefin porous film 1 ( figure 2 ) or both sides ( image 3 )conduct. The nano-ceramic material coating 2 mainly includes metal and non-metal oxides, nitrides, binders, and other additive materials. The binder usually adopts PVDF commonly used in lithium-ion batteries, or SBR series, or sodium polyacrylate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com