Wheat conditioning method through enzyme method

A wheat, conditioning technology, applied in application, grain processing, grain milling, etc., can solve the problems affecting the quality and safety of flour, the growth of various microorganisms, and the increase of conditioning warehouse capacity, so as to reduce the content of microorganisms and increase production efficiency. , the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

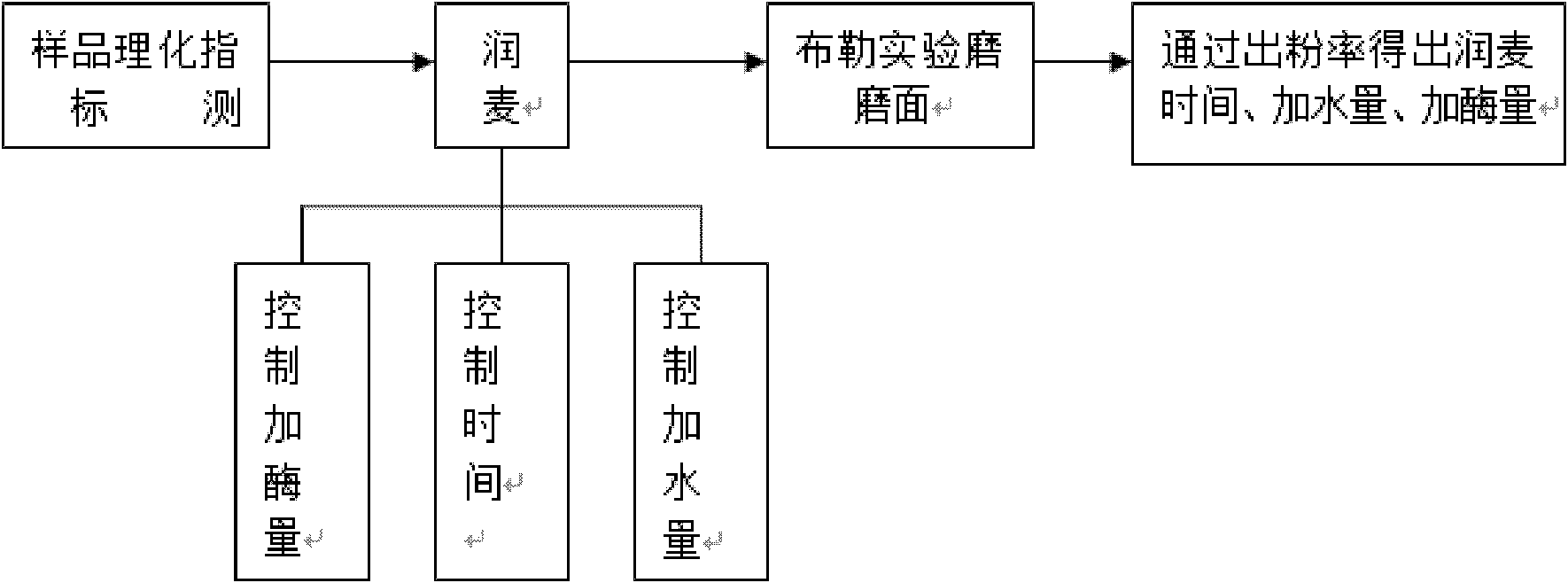

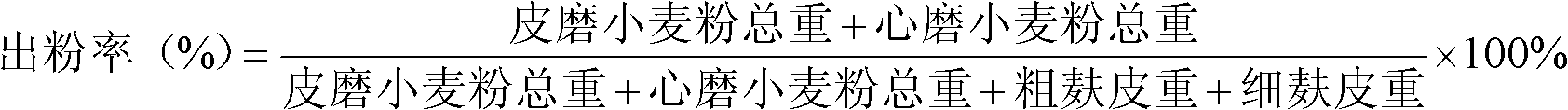

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

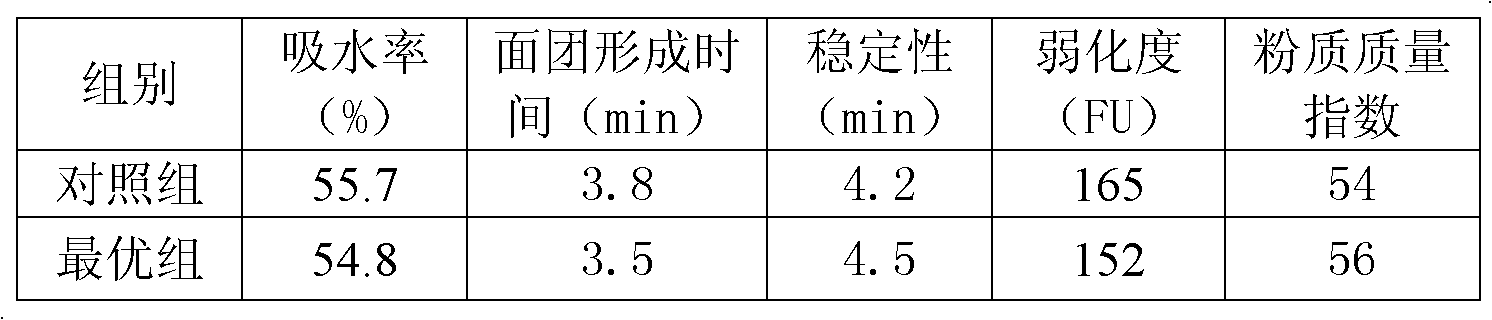

[0015] In order to shorten the tempering time by using a suitable enzyme preparation, the present invention has carried out systematic research from the following aspects. First study the various parts of wheat grains, and the composition of each part, the main purpose is to determine the different chemical compositions of different parts of wheat grains, to determine the enzyme preparations that need to be used (selection of cellulase and pentosanase by experimental comparison) ); In addition, the difference in the effect of the selected enzyme preparation is studied to determine the single addition or mixed addition ratio of cellulase and pentosanase; the powder quality of different experimental groups is studied to determine the action of the enzyme preparation .

[0016] In order to realize the present invention, at first raw material wheat adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com