Combined cleaning equipment of raw grain air sieve

A technology of cleaning equipment and air screen, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of increasing storage, processing, logistics costs, inability to separate out, difficulty in grain storage, and processing, so as to maintain health and The effect of safe production, guaranteed strength, and avoiding impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

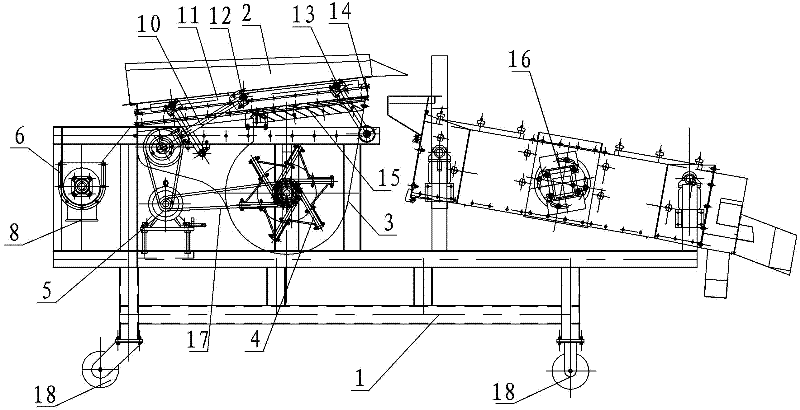

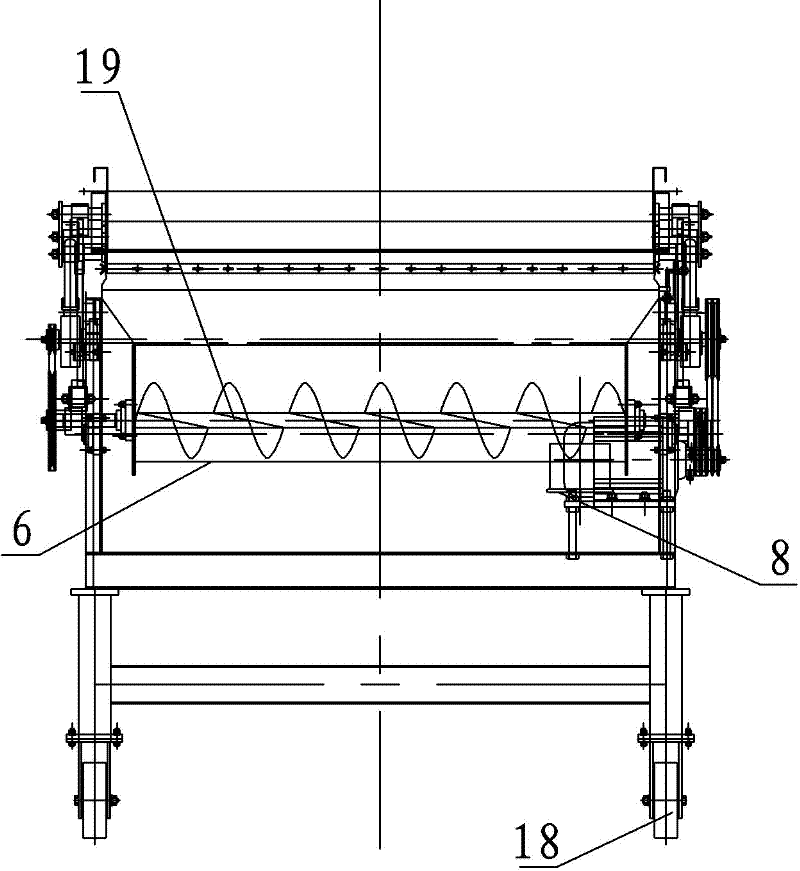

[0027] Embodiment one: see Figure 1-4 In the figure, a raw grain air sieve combined cleaning equipment includes a frame, a winnowing screen, a crank linkage mechanism, a blowing system, a transmission system, a dust collection hood, a vibrating grading screen, and a light miscellaneous screw conveyor; the blowing system It includes a bellows, a blower rotor, and a grille. The transmission system includes a motor, a belt, and a pulley. The dustpan-shaped trough is a dustpan-shaped trough, and scale holes are distributed on the bottom plate. There is an angle between the bottom surface of the dustpan and the horizontal plane. α, the winnowing screen is connected to the frame through the support rocker to form a four-bar linkage mechanism, and the crank linkage mechanism drives the four-bar linkage mechanism to form a crank four-bar linkage mechanism; the front end of the winnowing screen corresponds to the entrance of the vibrating grading screen , there is an included angle β ...

Embodiment 2

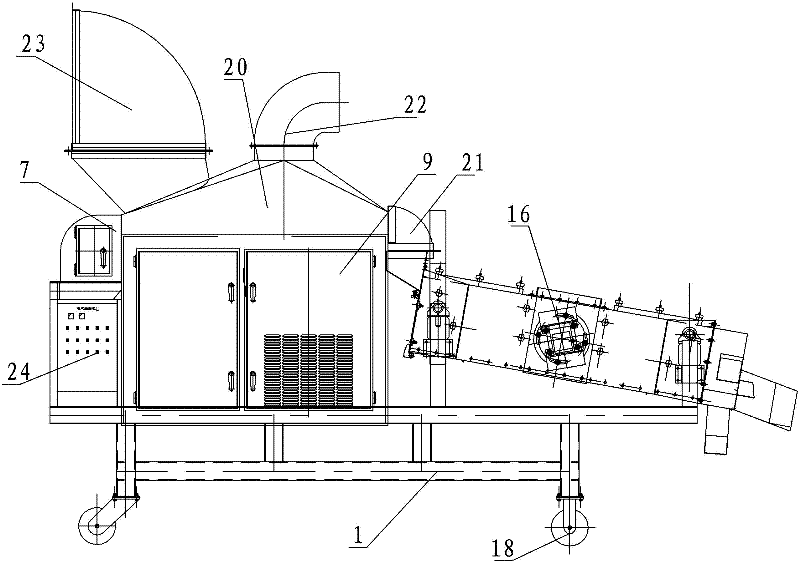

[0028] Embodiment two: see Figure 5 , The difference between the second embodiment and the first embodiment is that the dust outlet on the cover is connected to the dust collector with the induced draft fan through a pipeline, and other parts of the structure are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com