Single-horizontal shaft vibration stirrer

A vibrating mixing and mixer technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems affecting the operation quality and efficiency of mixing equipment, the difficulty of achieving microscopic uniformity of the mixture, and the inability to obtain good mixing. and other problems, to achieve the effect of improving the low-efficiency area of stirring, easy to ensure bearing life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

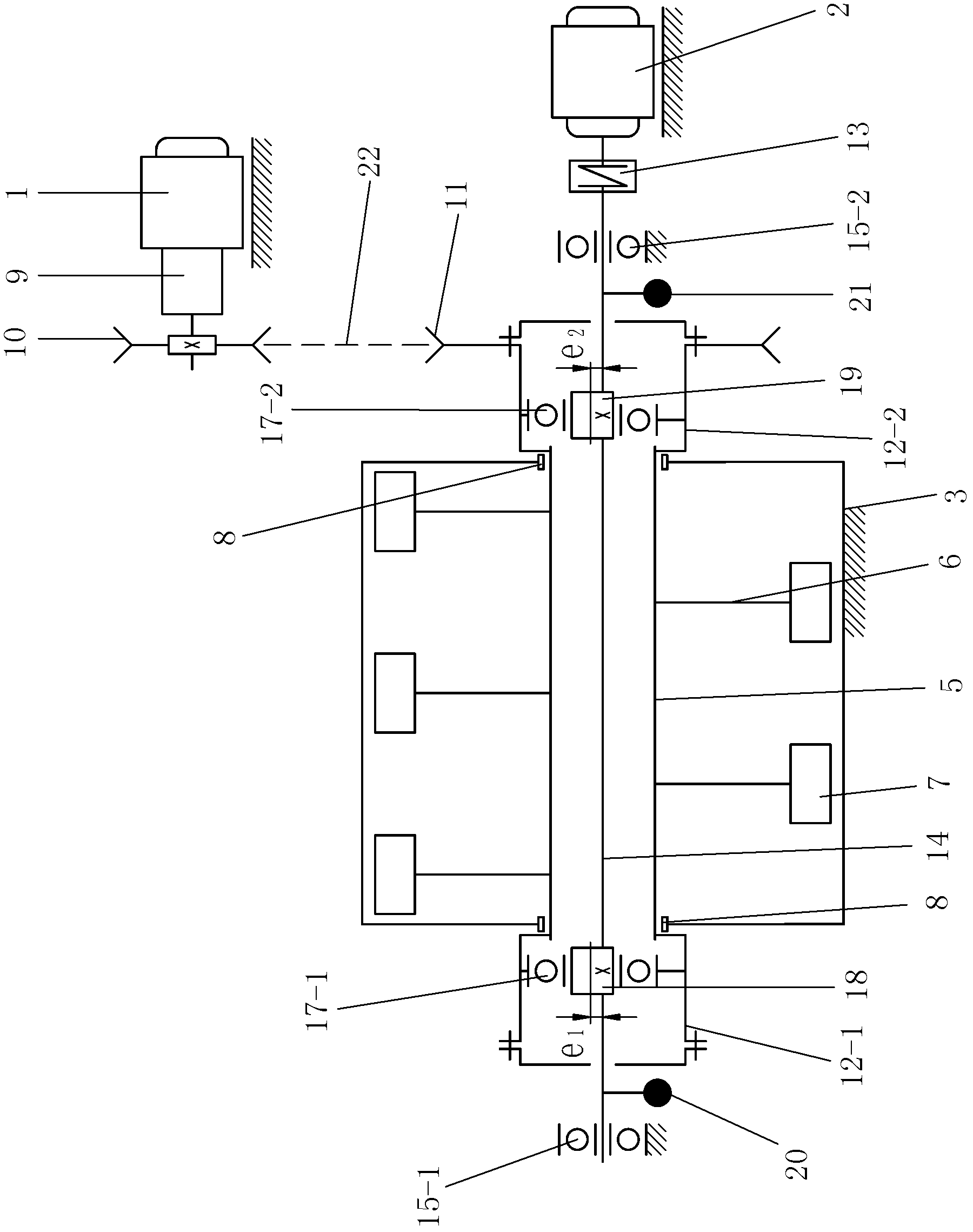

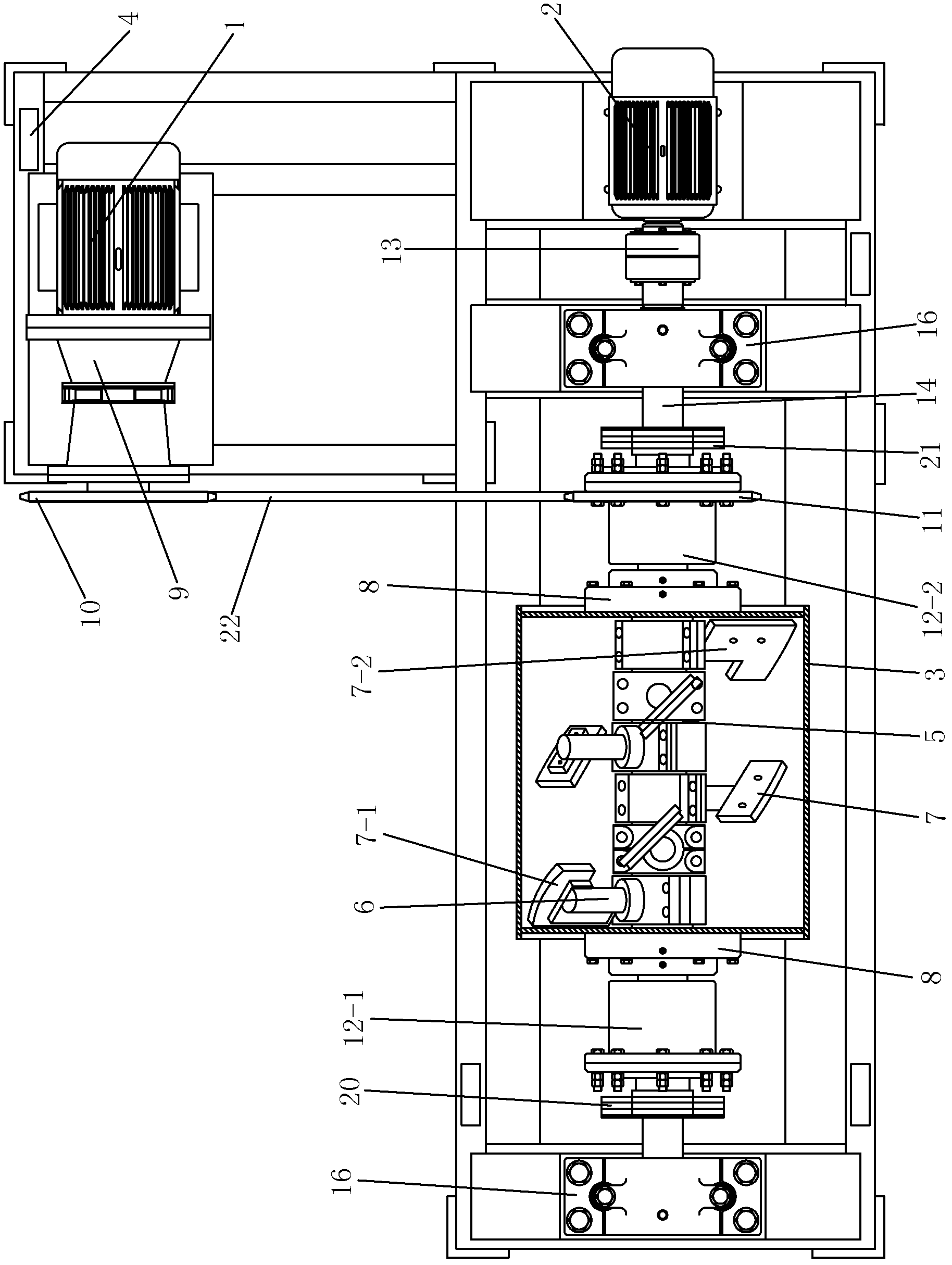

[0030] Such as figure 1 , image 3 , Figure 4 and Figure 5As shown, a single-horizontal shaft vibratory mixer includes a frame 4, a stirring transmission device, a vibration transmission device, a vibration stirring device, a stirring drive motor 1 and a vibration drive motor 2, and the stirring drive motor 1 and the vibration drive motor 2 are both Set on one side of the vibration stirring device or the stirring drive motor 1 and the vibration driving motor 2 are respectively arranged on both sides of the vibration stirring device, the stirring drive motor 1 passes through the stirring transmission device and the vibration stirring device Connect and drive the vibration stirring device to stir, the vibration driving motor 2 is connected with the vibration stirring device through the vibration transmission device and drives the vibration stirring device to generate vibration, the stirring driving motor 1 and the vibration driving motor 2 are fixed on the frame 4 The vibra...

Embodiment 2

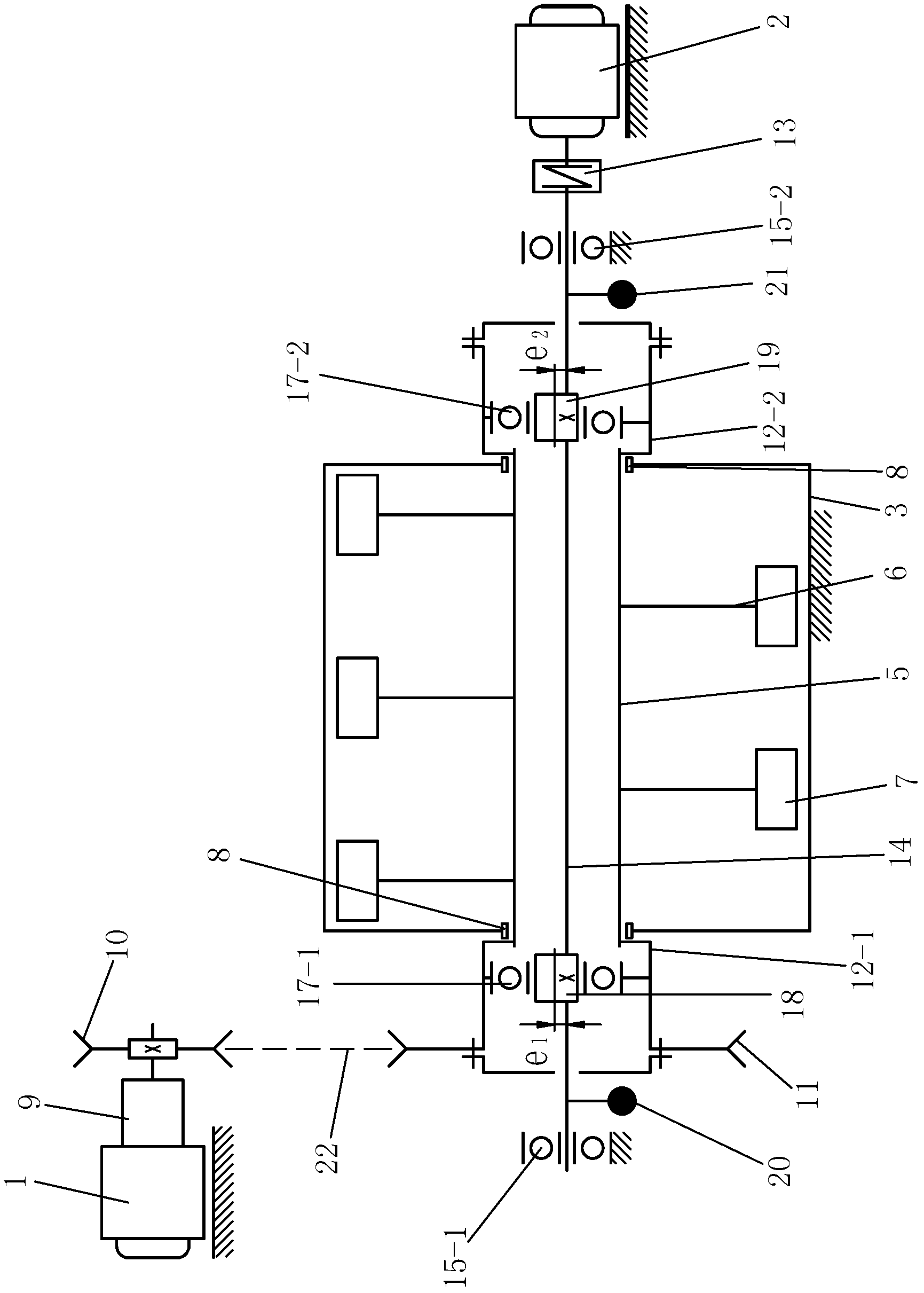

[0042] The difference from Embodiment 1 is that the stirring drive motor 1 and the vibration drive motor 2 are respectively arranged on both sides of the vibration stirring device, and the large sprocket 11 is fixedly installed on the outer wall of the first stirring sleeve 12-1 On, the output shaft of described vibration drive motor 2 is connected with the left end of vibration shaft 14 through coupling 13 (as figure 2 shown).

[0043] The working process of the present invention is: after putting each raw material that concrete is formed into in the mixing drum 3, start the stirring drive motor 1 and the vibration drive motor 2 simultaneously or delay starting the vibration drive motor 2 after starting the stirring drive motor 1 for a few seconds, then stir The driving motor 1 outputs stirring power, drives the small sprocket 10 to rotate through the reducer 9, and then drives the large sprocket 11 and the stirring sleeve 12 fixedly connected to it to rotate through the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com