Bulk polymerization production process of ABS (Acrylonitrile Butadiene Styrene) resin and application of static mixer

A technology of ABS resin and static mixing, applied in the field of bulk polymerization production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

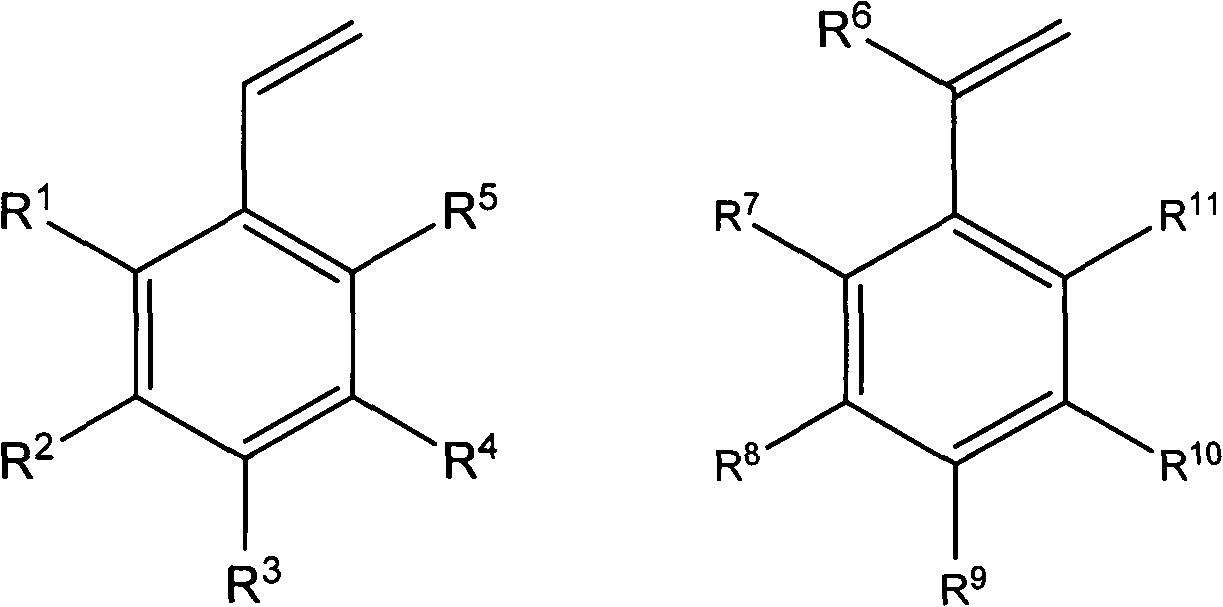

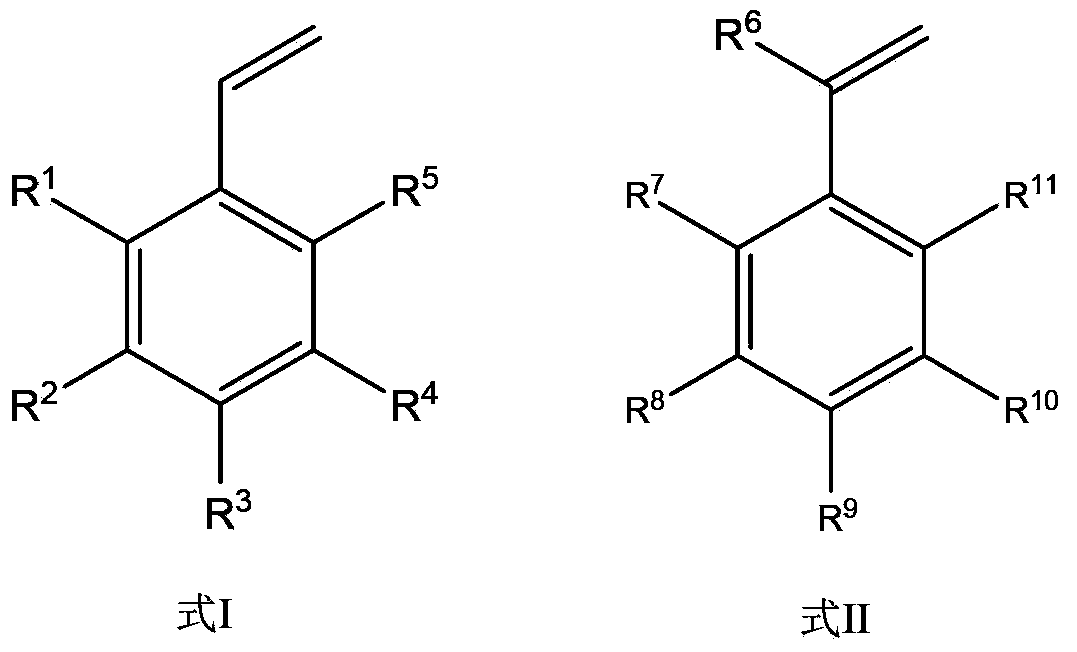

Method used

Image

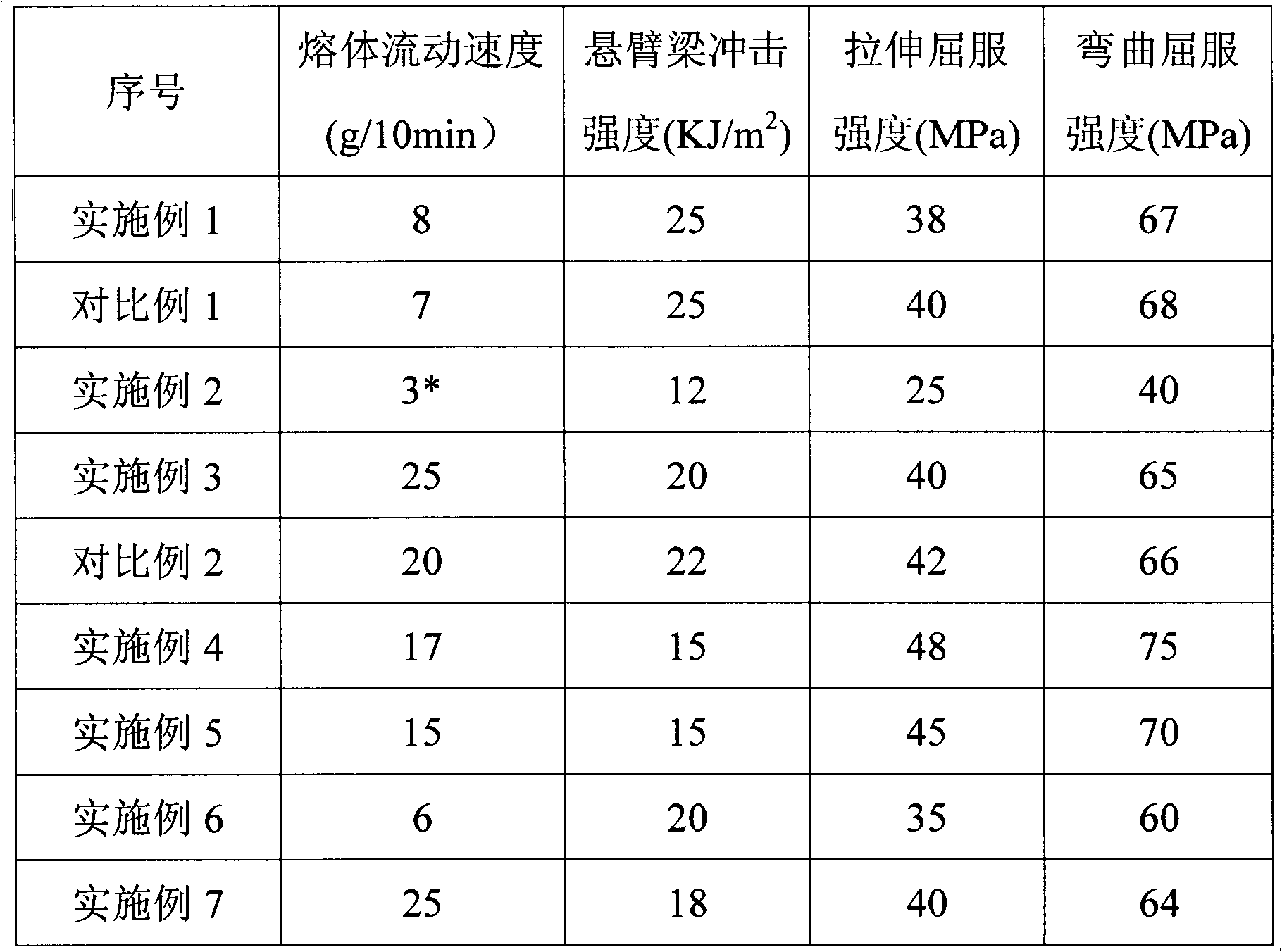

Examples

Embodiment 1

[0053] Both the first and second reactors are CSTR reactors, the first reactor is used as a reactor for the rubber grafting process, and the second reactor is used as a reactor for the phase inversion process.

[0054] The reaction mixture in the first reactor includes: (1) rubber solution: styrene 65%, acrylonitrile 21%, butadiene rubber 14% (relative to the percentage of rubber solution). The cis-structure content in the butadiene rubber used is 40%, and the 1,2-structure content is 13%; (2) tert-butyl peroxyneodecanoate 0.03%; (3) α-methylstyrene dimer 0.05%; (4) 20% ethylbenzene (relative to the percentage of rubber solution).

[0055] Add mercaptan 0.05% to the second reactor.

[0056] Production Process:

[0057] (1) Rubber grafting process: the rubber solution is added into the first reactor to carry out grafting reaction, the reaction temperature is 70°C, and the dry matter content of the reaction mixture in the first reactor is controlled to be 18wt%;

[0058] (2) ...

Embodiment 2

[0065] Both the first and second reactors are CSTR reactors, the first reactor is used as a reactor for the rubber grafting process, and the second reactor is used as a reactor for the phase inversion process.

[0066] The reaction mixture in the first reactor includes: (1) rubber solution: styrene 70%, acrylonitrile 25%, butadiene rubber 5% (relative to the percentage of rubber solution). The cis-structure content in the butadiene rubber used is 35%, and the 1,2-structure content is 30%; (2) tert-butyl peroxypivalate 0.01%; (3) α-methylstyrene dimer 0.1%; (4) 30% toluene (relative to the percentage of rubber solution).

[0067] Add mercaptan 0.1% to the second reactor.

[0068] Production Process:

[0069] (1) Rubber grafting process: rubber solution is joined in the first reactor and carries out grafting reaction, and reaction temperature is 85 ℃, and the dry matter content of the reaction mixture in the control described first reactor is 18wt%,

[0070] (2) Phase transit...

Embodiment 3

[0075] Both the first and second reactors are CSTR reactors, the first reactor is used as a reactor for the rubber grafting process, and the second reactor is used as a reactor for the phase inversion process.

[0076] The reaction mixture in the first reactor includes: (1) rubber solution: styrene 66%, acrylonitrile 21%, styrene-butadiene rubber 13% (relative to the percentage of the rubber solution). Butadiene content is 60% in the styrene-butadiene rubber used, and styrene content is 40%; (2) tert-butyl peroxypivalate 0.02%; (3) α-methylstyrene dimer 0.01%; ( 4) Ethylbenzene 20% (relative to the percentage of the rubber solution); (5) The third monomer itaconate acrylate 5%.

[0077] Add mercaptan 0.2% to the second reactor.

[0078] Production Process:

[0079] (1) Rubber grafting process: the rubber solution is added into the first reactor to carry out grafting reaction, the reaction temperature is 75°C, and the dry matter content of the reaction mixture in the first re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com