Improvement process for bulk polymerization of ABS resin

A technology of ABS resin and bulk polymerization, which is applied in the field of improved technology of bulk polymerization ABS resin, to achieve high production conversion rate, reduce energy consumption, reduce investment and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

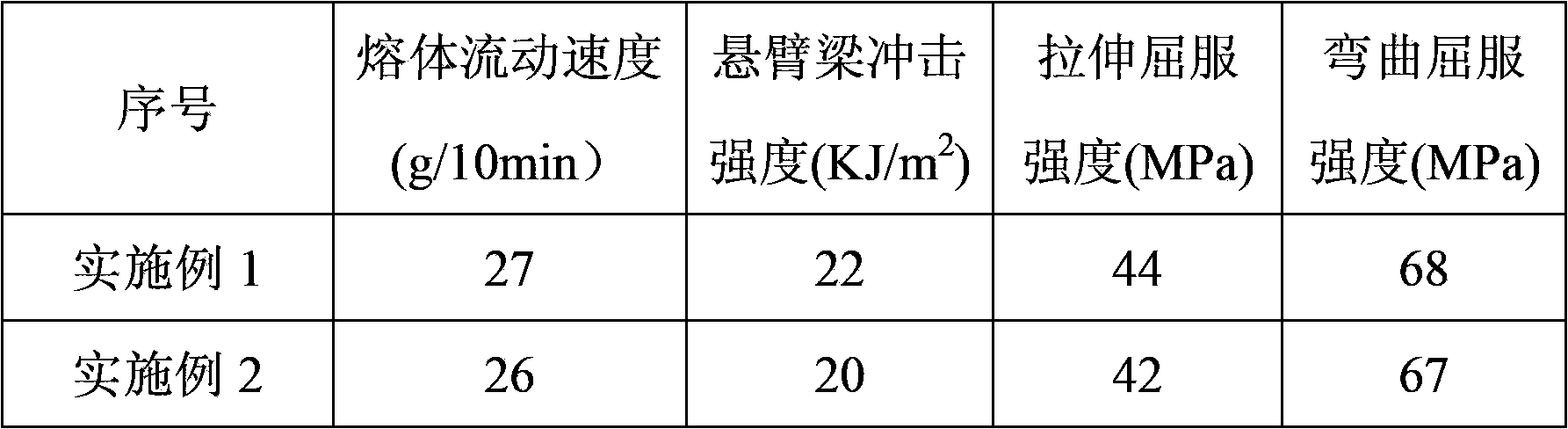

Examples

Embodiment 1

[0043] The first reactor is a static mixing reactor, the second reactor is a CSTR reactor, the first reactor is used as a reactor for the rubber grafting process, and the second reactor is used as a reactor for the phase inversion process.

[0044] The reaction mixture in the first reactor includes: (1) Rubber solution: 45% styrene, 45% acrylonitrile, and 10% styrene-butadiene rubber (percentage relative to the rubber solution). The butadiene content in the styrene-butadiene rubber used is 70%, and the styrene content is 30%; (2) tert-butyl peroxypivalate 0.02%; (3) α-methylstyrene dimer 0.04%; ( 4) Ethylbenzene 20% (relative to the percentage of rubber solution); (5) The third monomer butyl acrylate 2%.

[0045] Add mercaptan 0.15% in the second reactor.

[0046] Production Process:

[0047] (1) Rubber grafting process: the rubber solution is added to a static mixing reactor for grafting reaction. The conditions of the static mixing reactor are as follows: a. The porosity o...

Embodiment 2

[0053] The first reactor is a static mixing reactor, the second reactor is a stir-PFR reactor, the first reactor is used as a reactor for the rubber grafting process, and the second reactor is used as a reactor for the phase inversion process.

[0054] The reaction mixture in the first reactor includes: (1) Rubber solution: 50% styrene, 35% acrylonitrile, and 15% styrene-butadiene rubber (percentage relative to the rubber solution). The butadiene content in the styrene-butadiene rubber used is 70%, and the styrene content is 30%; (2) tert-butyl peroxypivalate 0.02%; (3) α-methylstyrene dimer 0.04%; ( 4) Ethylbenzene 20% (relative to the percentage of rubber solution); (5) The third monomer butyl acrylate 2%.

[0055] Add mercaptan 0.15% in the second reactor.

[0056] Production Process:

[0057] (1) Rubber grafting process: the rubber solution is added to a static mixing reactor for grafting reaction, and the conditions of the static mixing reactor are as follows: a. The poro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com