ABS production technology through bulk polymerization method

A technology of ABS resin and production process, which is applied in the field of manufacturing ABS resin to achieve continuous production, reduce investment and production costs, and avoid the effect of clogging the reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

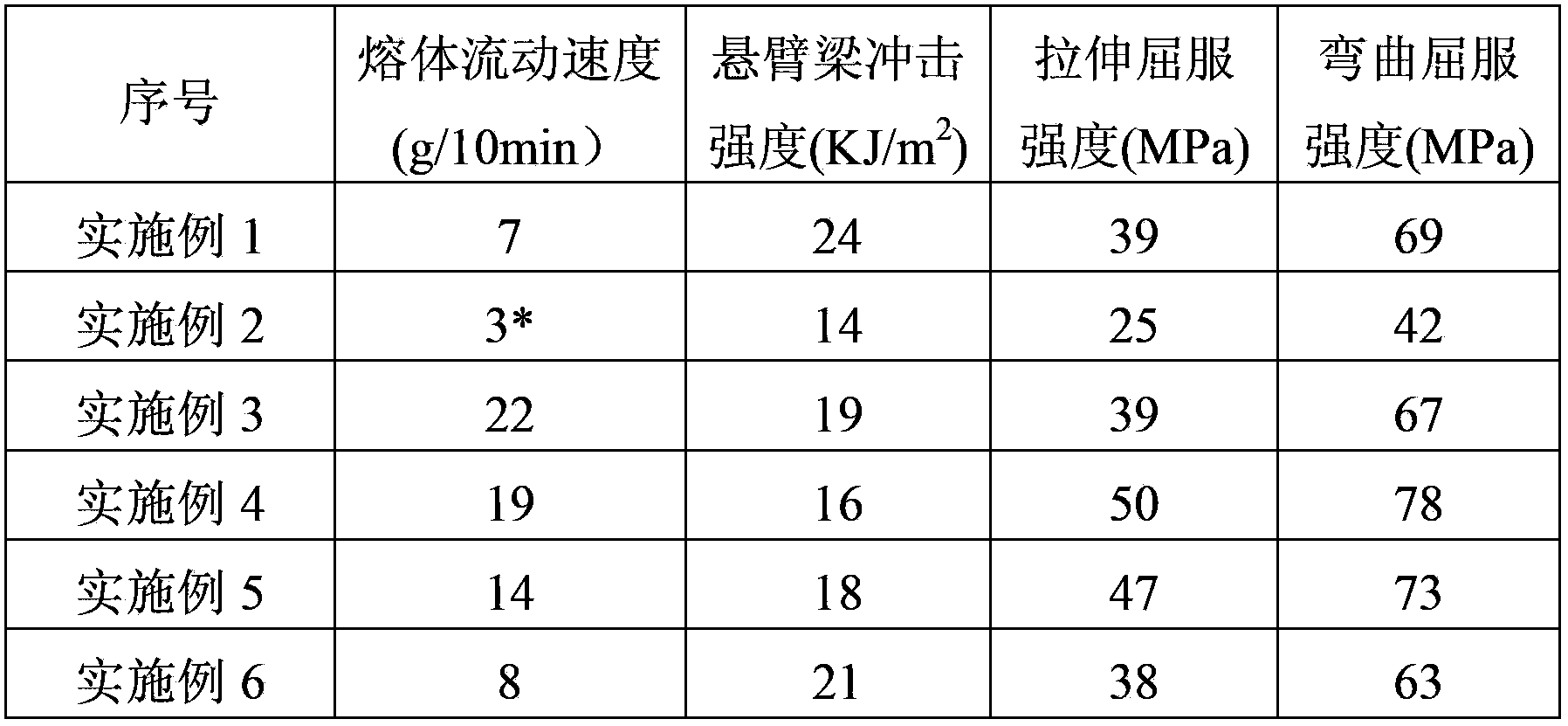

Examples

Embodiment 1

[0045] The reaction mixture in the continuous fully mixed flow reactor includes: (1) Rubber solution: 65% styrene, 21% acrylonitrile, 14% butadiene rubber (percentage relative to the rubber solution). The content of cis structure in the butadiene rubber used is 40%, and the content of 1,2-structure is 13%; (2) tert-butyl peroxyneodecanoate 0.03%; (3) α-methylstyrene dimer 0.05%; (4) 20% ethylbenzene (percentage relative to the rubber solution).

[0046] A 0.05% mercaptan was added to a stirred plug flow reactor.

[0047] Production Process:

[0048] (1) Rubber grafting process: the rubber solution is added to the continuous fully mixed flow reactor for grafting reaction, the reaction temperature is 70°C, and the dry matter content of the reaction mixture in the continuous fully mixed flow reactor is controlled to be 18wt% ;

[0049] (2) Phase transformation process: the reaction mixture in the continuous fully mixed flow reactor was discharged into a plug flow reactor with ...

Embodiment 2

[0054] The reaction mixture in the continuous fully mixed flow reactor includes: (1) Rubber solution: 70% styrene, 25% acrylonitrile, 5% butadiene rubber (percentage relative to the rubber solution). The content of cis structure in the butadiene rubber used is 35%, and the content of 1,2-structure is 30%; (2) tert-butyl peroxypivalate 0.01%; (3) α-methylstyrene dimer 0.1%; (4) 30% toluene (percentage relative to the rubber solution).

[0055] A 0.1% mercaptan was added to a stirred plug flow reactor.

[0056] Production Process:

[0057](1) Rubber grafting process: the rubber solution is added to the continuous fully mixed flow reactor for grafting reaction, the reaction temperature is 75°C, and the dry matter content of the reaction mixture in the continuous fully mixed flow reactor is controlled to be 18wt% ,

[0058] (2) Phase transformation process: The reaction mixture in the continuous fully mixed flow reactor was discharged into a plug flow reactor with stirring, and...

Embodiment 3

[0063] The reaction mixture in the continuous fully mixed flow reactor includes: (1) Rubber solution: 66% styrene, 21% acrylonitrile, 13% styrene-butadiene rubber (percentage relative to the rubber solution). The butadiene content of the styrene-butadiene rubber used is 60% and the styrene content is 40%; (2) t-butyl peroxypivalate 0.02%; (3) α-methylstyrene dimer 0.01%; ( 4) Ethylbenzene 20% (percentage relative to the rubber solution); (5) Itaconic acrylate, the third monomer, 5%.

[0064] A 0.2% mercaptan was added to a stirred plug flow reactor.

[0065] Production Process:

[0066] (1) Rubber grafting process: the rubber solution is added to the continuous fully mixed flow reactor for grafting reaction, the reaction temperature is 75°C, and the dry matter content of the reaction mixture in the continuous fully mixed flow reactor is controlled to be 20wt% ;

[0067] (2) Phase transformation process: The reaction mixture in the continuous fully mixed flow reactor was dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com