Activated rubber particle, preparation method and application thereof

A technology of rubber granules and activator, applied in building components, building insulation materials, buildings, etc., can solve the problems of high fiber content, poor asphalt modification effect, high energy consumption, etc., and achieve high storage stability and good dispersion. , the system uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 100kg of car tire rubber powder, 40kg of petroleum resin, 0.5kg of activator, and 0.5kg of compatibilizer. After premixing the above raw materials, they are extruded and granulated through a twin-screw extruder at 240°C. 50rpm;

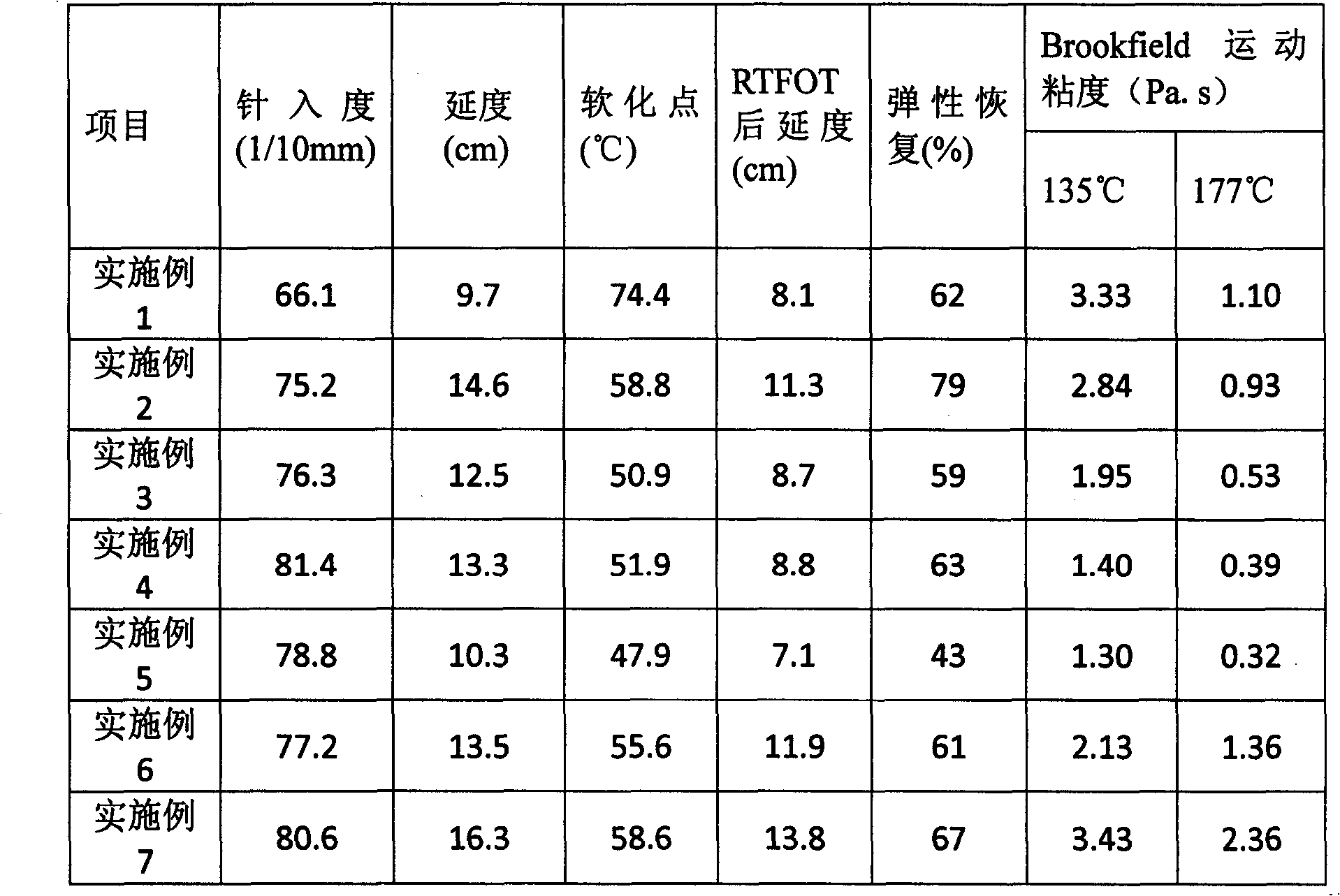

[0028] (2) The activated rubber powder particles obtained in step (1) were added to asphalt at 150° C., the mass ratio of activated rubber powder particles to asphalt was 1:4, and the modified asphalt was obtained by shearing for 10 minutes. The conventional performance indicators of modified asphalt are shown in Table 1.

Embodiment 2

[0030] (1) Weigh 100kg of car tire rubber powder, 10kg of petroleum resin, 0.7kg of activator and 0.5kg of compatibilizer. 200rpm;

[0031] (2) Add the activated rubber powder particles obtained in step (1) to asphalt at 170° C., the mass ratio of activated rubber powder particles to asphalt is 1:4, and stir for 15 minutes to obtain modified asphalt. The conventional performance indicators of modified asphalt are shown in Table 1.

Embodiment 3

[0033] (1) Weigh 100kg of car tire rubber powder, 25kg of petroleum resin, 1kg of activator, and 0.5kg of compatibilizer. After premixing the above raw materials, extrude and granulate through a twin-screw extruder at 260 ° C. The screw speed is 100rpm;

[0034] (2) Add the activated rubber powder particles obtained in step (1) to asphalt at 180° C., the mass ratio of activated rubber powder particles to asphalt is 1:4, and stir for 15 minutes to obtain modified asphalt. The conventional performance indicators of modified asphalt are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com