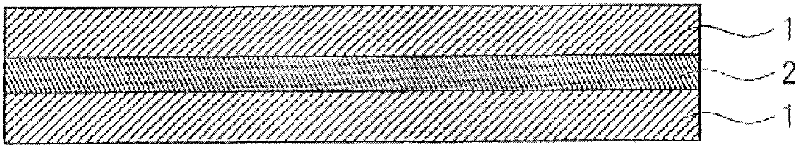

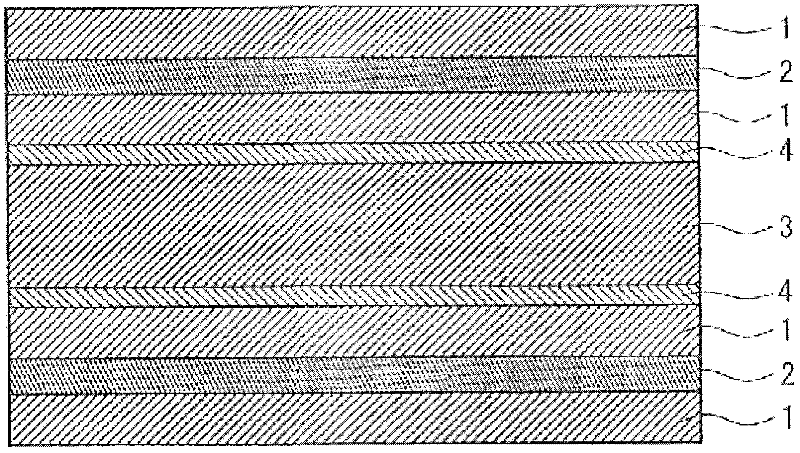

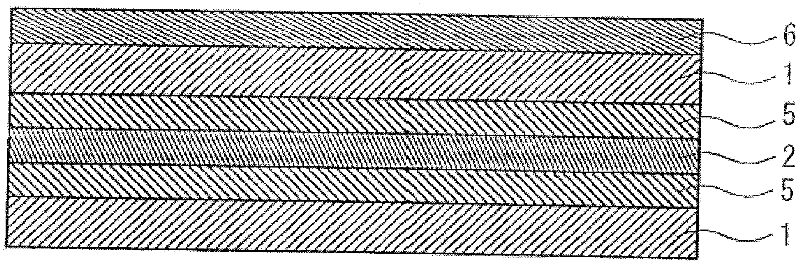

Protection sheet and polarizing plate

A protection sheet, disperse phase technology, applied in optics, optical elements, polarizing elements, etc., can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Hereinafter, the present invention will be specifically described based on the examples of the present invention, but the present invention is not limited to these examples.

[0107] Add acrylic rubber and ultraviolet absorber to the heat-resistant acrylic resin, use the extruder of the T-die device, and adjust the number of revolutions of the screw, the temperature of the resin in the cylinder (cylinder) of the extruder, and the T-die (T-die) temperature extruded to obtain a variety of protective sheets. As the ultraviolet absorber, TINUVIN360 and TINUVIN1577 manufactured by BASF Japan Co., Ltd., and SEESORB707 and SEESORB709 manufactured by Shipro Chemical Co., Ltd. were used. Various types of protective sheets with a thickness of 40 μm were obtained by using one or two of the above-mentioned four kinds of ultraviolet absorbers and changing the addition amount with respect to 100 parts by mass of the heat-resistant acrylic resin. The transmittances Tt (%) of light ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com