Damascus technology for forming metal protective layer on copper interconnecting wire

A metal protection layer, copper interconnection technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems affecting electrical uniformity and reliability, unfavorable metal protection layer thickness, dielectric layer dielectric constant Reduce and other problems to achieve the effect of reducing the effective dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

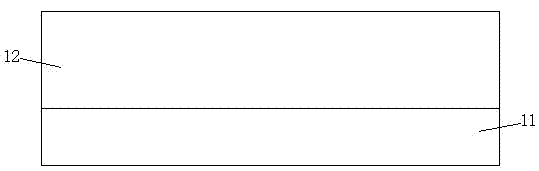

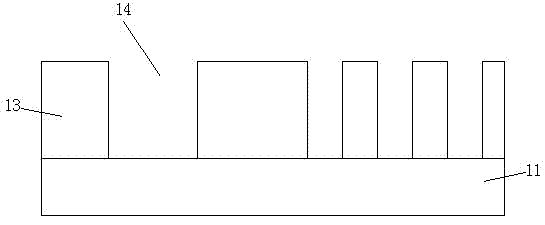

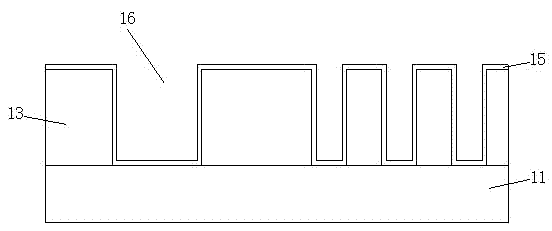

[0023] Figure 1-10 It is a schematic flow chart of the damascene process structure with a metal protective layer on the copper interconnection line of the present invention. Such as Figure 1-10 Shown, a kind of copper interconnection of the present invention has the damascene process of metal protective layer:

[0024] First, a low dielectric constant (Low-k) material made of SiOCH is deposited on the substrate 11 by chemical vapor deposition (Chemical Vaporous Deposition, referred to as CVD) or spin coating (Spin-on Deposition, referred to as SOD) process. material to cover the substrate 11; continue to etch the first dielectric layer 12 to the substrate 11 using a single damascene etching process to form copper embedded in the remaining first dielectric layer 13 after etching Interconnect trenches 14 .

[0025] After that, physical vapor dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com