A novel substrate integrated ridge waveguide structure

A technology of substrate integration and ridge waveguide, applied in the field of microwave guide, can solve problems such as incompatibility, and achieve the effect of improving the working bandwidth, increasing the ridge capacitance value, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments illustrate the novel substrate-integrated ridge waveguide structure of the present invention in detail with reference to the accompanying drawings.

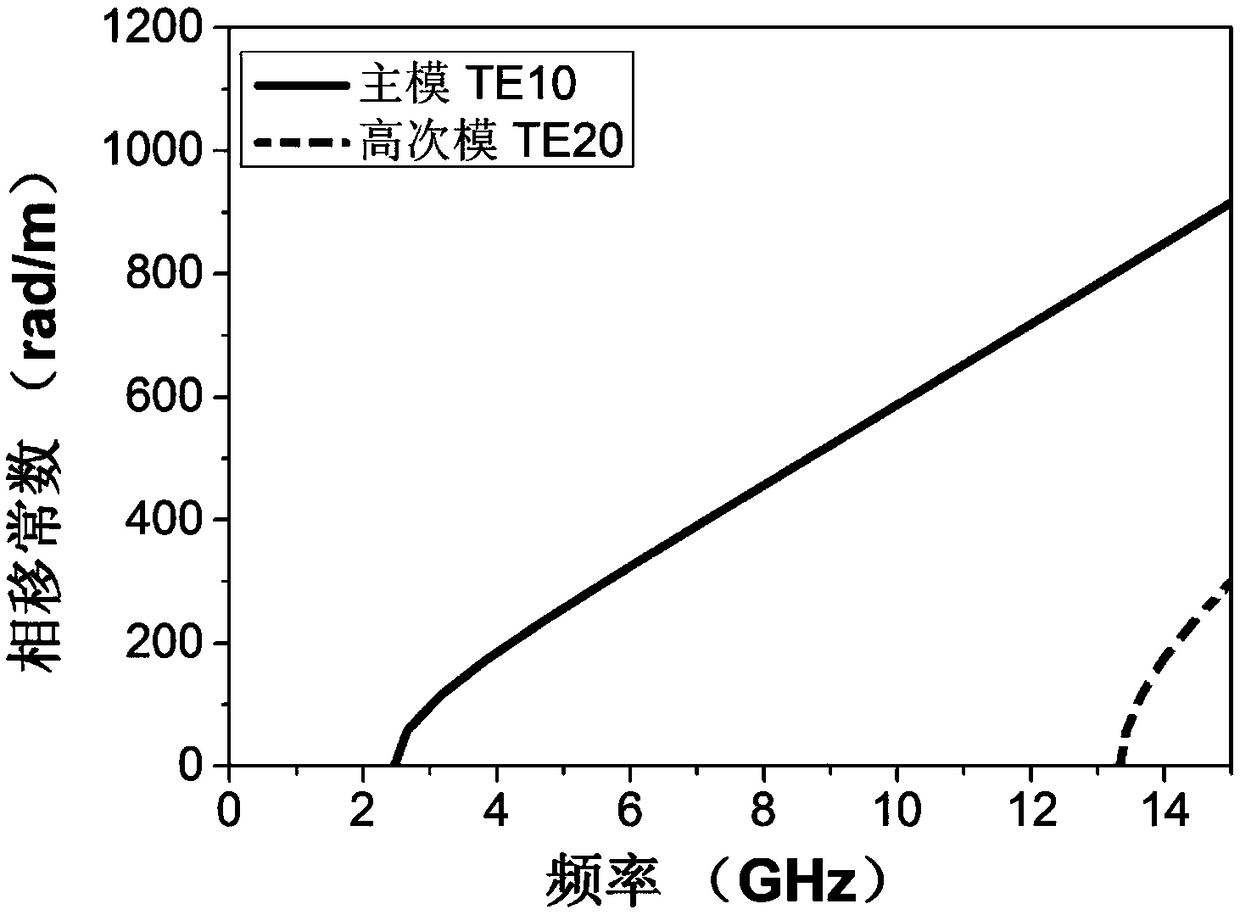

[0020] The main mode of the substrate integrated ridge waveguide structure 100 in this embodiment transmits the TE10 mode, and the high-order mode transmits the TE20 mode, and the working bandwidth of the main mode is the cut-off frequency of the high-order mode TE20 mode and the cut-off frequency of the main mode TE10 mode difference.

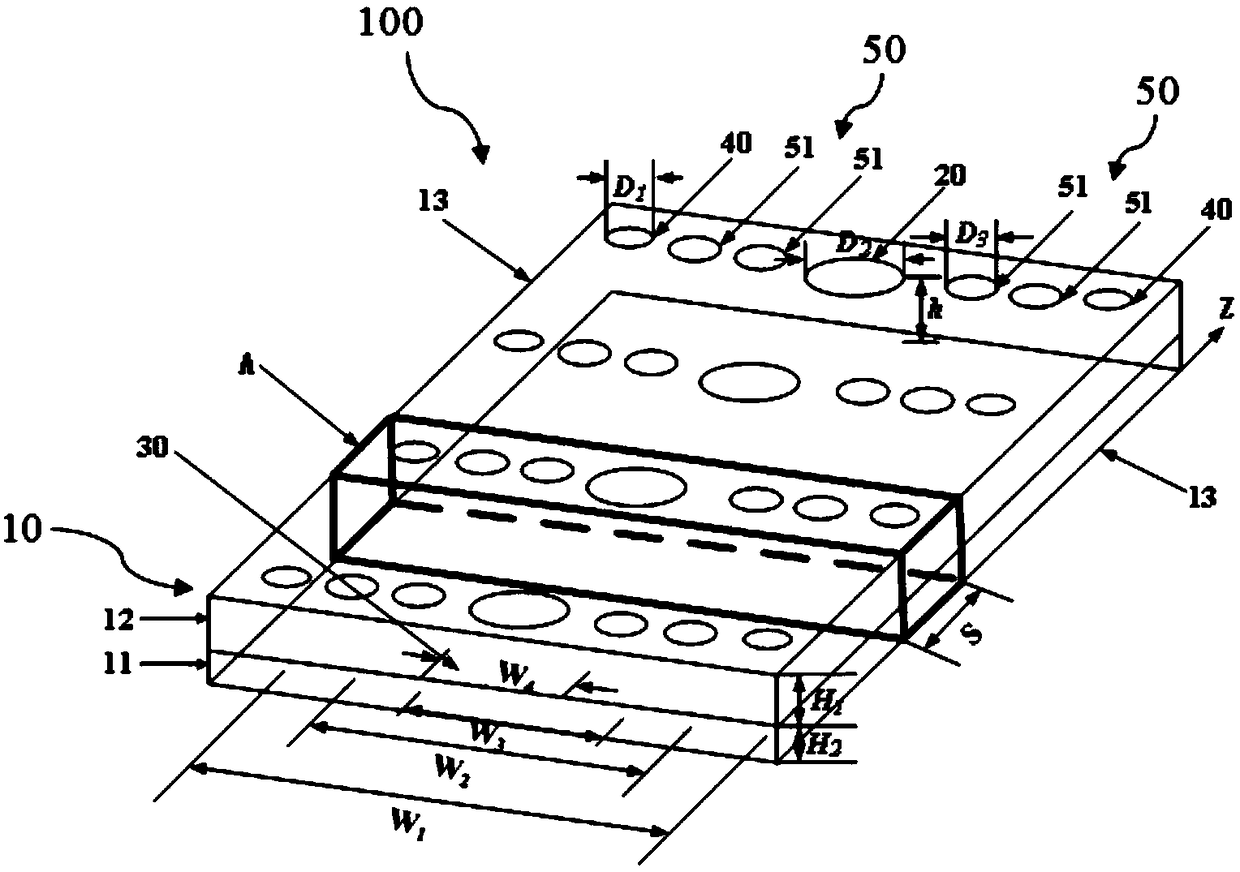

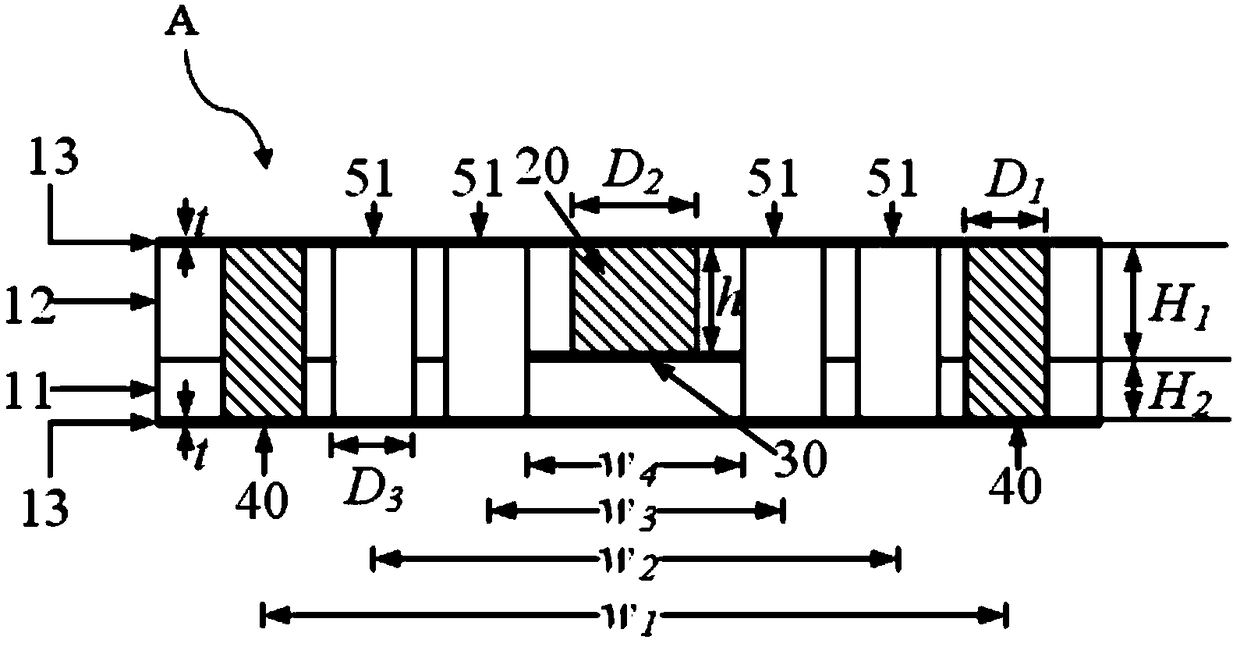

[0021] figure 1 is a structural schematic diagram of a novel substrate-integrated ridge waveguide structure in an embodiment of the present invention.

[0022] Such as figure 1 As shown, the novel substrate-integrated ridge waveguide structure 100 includes a dielectric substrate unit 10 , suspended metal pillars 20 , metal strips 30 , a pair of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com