Dielectric barrier discharge enhanced-type low-temperature plasma brush generation device

A technology of dielectric barrier discharge and low-temperature plasma, which is applied in the direction of plasma and electrical components, can solve the problems of wasting energy and consumption, and achieve the effects of prolonging service life, less Joule heat, and stabilizing plasma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

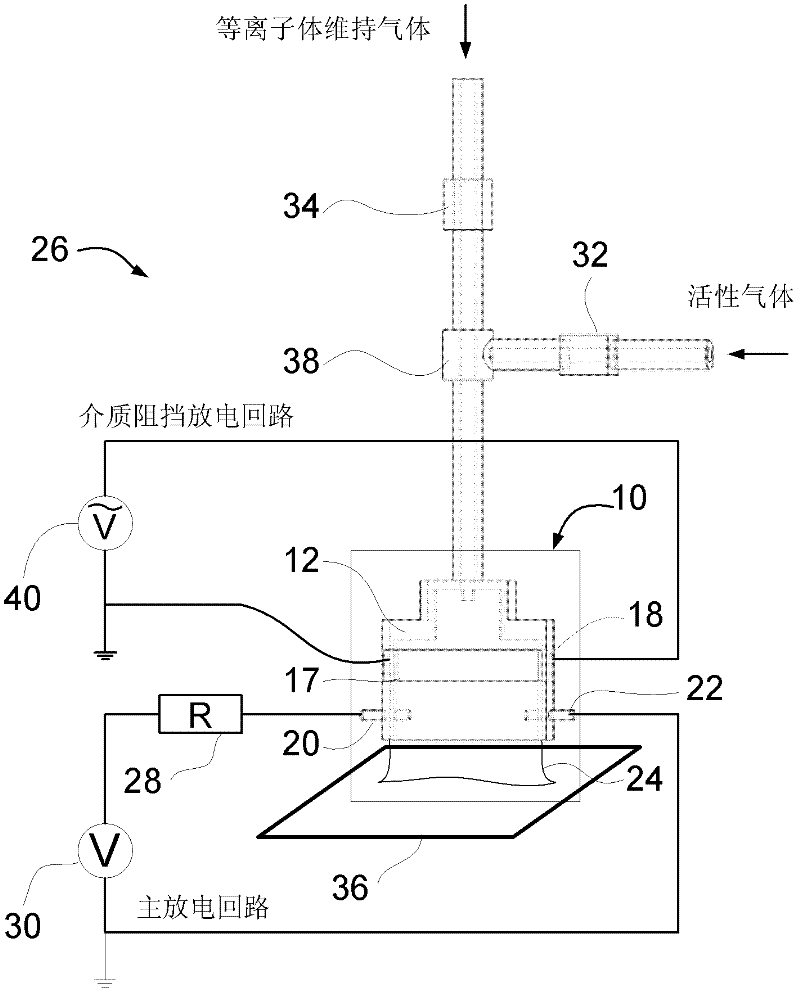

[0026] The working principle of the present invention is: before the main discharge of the plasma brush is generated, the working gas (plasma maintenance gas and / or active gas) is pre-discharged, part of the gas is ionized, and part of the pre-ionized working gas flows through the The main discharge area is discharged. During the main discharge, the ionized positive and negative ions and even a small amount of electrons in the gas can reduce the breakdown threshold of the gas, thereby reducing the initial voltage of the main discharge, and can further appropriately reduce the rated operating voltage and current, which not only reduces It not only reduces the energy required for the generation of plasma itself, but also reduces the Joule heat consumed by the current limiting resistor, which saves energy to a large extent.

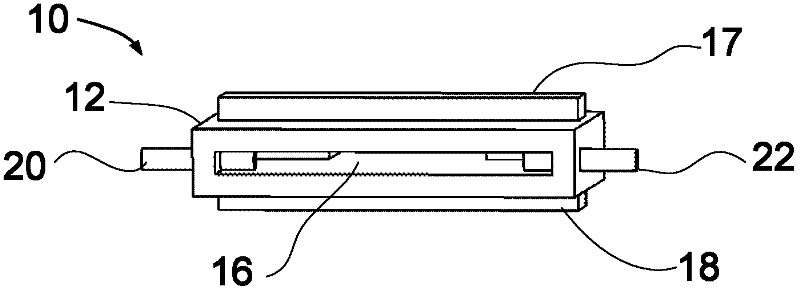

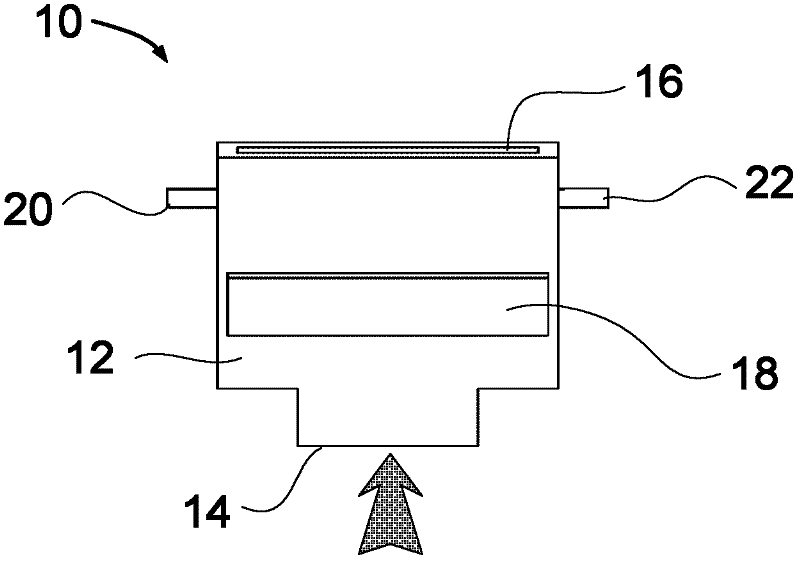

[0027] Such as figure 1 , figure 2 As shown, compared with the original device (the scheme of ZL201120020842.5), the structural improvement of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com