Ammonium sulfate wastewater treatment method during acrylonitrile production process

A production process and wastewater treatment technology, applied in natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as high COD value, unfriendly environment, high total cyanide, etc., to achieve removal Thorough, environmentally friendly results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

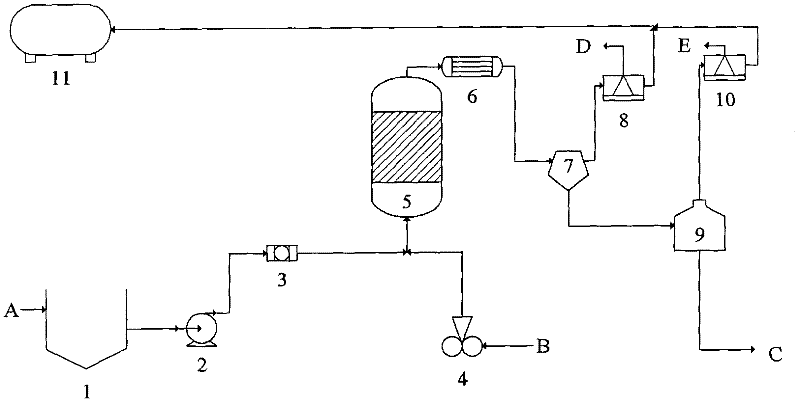

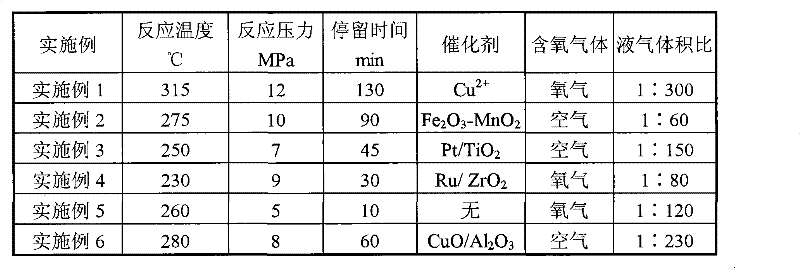

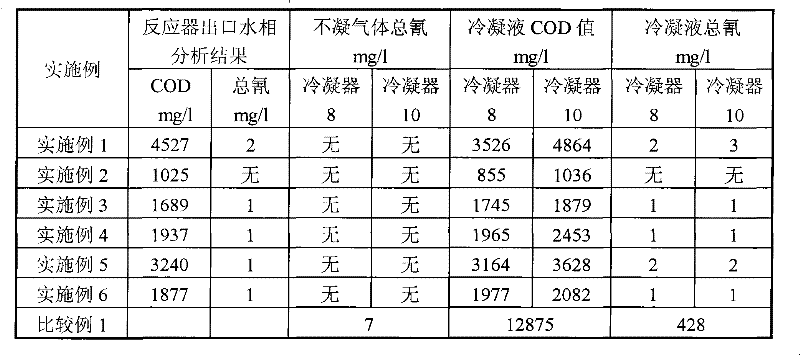

[0013] according to figure 1 As shown, the properties of ammonium sulfate wastewater are shown in Table 1, and the wet oxidation reaction conditions are shown in Table 2. After the reaction, analyze the COD and total cyanide of the water phase at the outlet of reactor 5 and the condensed water of condensers 8 and 10, and analyze condensers 8 and 10 simultaneously. The content of total cyanide in the noncondensable gas, the results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com