Lubricating oil for dimethyl ether engine

A technology of lubricating oil and engine, applied in the field of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

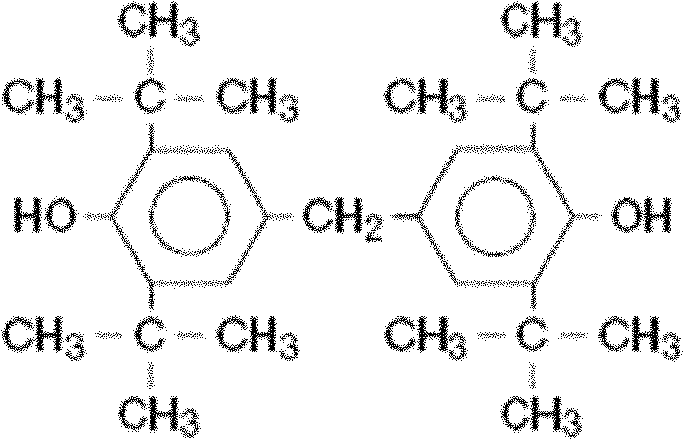

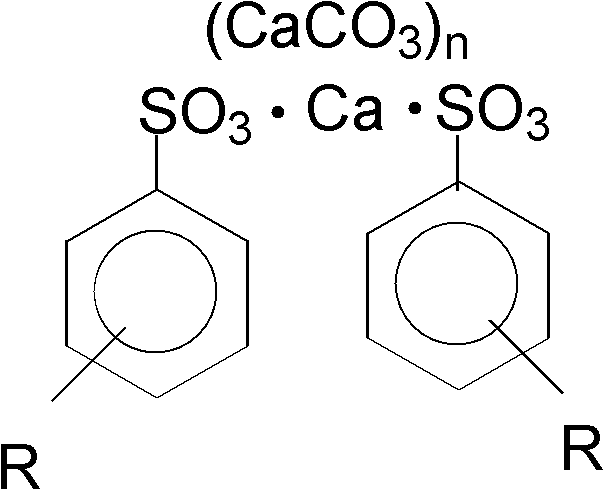

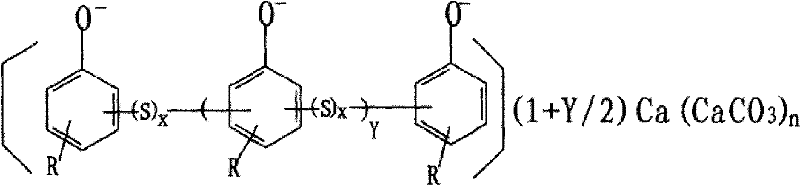

[0033] Prepare a full-component 15W-40 dimethyl ether engine lubricating oil, which contains neutral base oil, shielding phenol, branched chain alkylphenol or branched chain alkylphenol calcium, long-chain alkaryl sulfonate calcium, sulfurized alkyl Calcium phenate, polyisobutylene succinimide ashless dispersant, zinc dialkyl dithiophosphate, viscosity index improver, pour point depressant. The relevant data thus obtained can be seen in Table 1.

[0034] Table 1

[0035]

[0036]

Embodiment 2

[0038] Formulate a full-component 15W-40 dimethyl ether engine lubricant, which contains neutral base oil, shielding phenol, branched chain alkylphenol and branched chain alkylphenol calcium, long chain alkaryl sulfonate calcium, sulfurized alkyl Calcium phenate, polyisobutylene succinimide ashless dispersant, zinc dialkyl dithiophosphate, viscosity index improver, pour point depressant. The relevant data thus obtained can be seen in Table 2.

[0039] Table 2

[0040]

Embodiment 3

[0042] Formulate a full-component 15W-40 dimethyl ether engine lubricant, which contains neutral base oil, shielding phenol, branched chain alkylphenol and branched chain alkylphenol calcium, long chain alkaryl sulfonate calcium, sulfurized alkyl Calcium phenate, polyisobutylene succinimide ashless dispersant, zinc dialkyl dithiophosphate, viscosity index improver, pour point depressant. The relevant data thus obtained can be seen in Table 3.

[0043] table 3

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com