Testing system for pressure and temperature of supersonic engine plume field

A technology of engine and supersonic speed, which is applied in the field of measurement, can solve problems such as the surge of test cost, and achieve the effect of reducing test time, adding less disturbance, and high response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

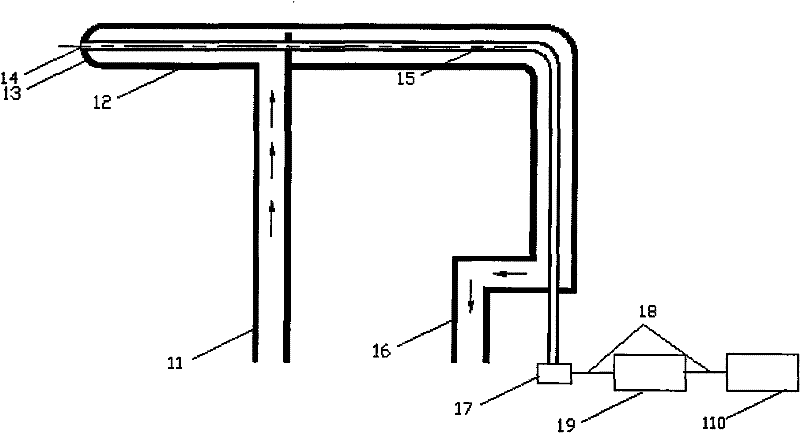

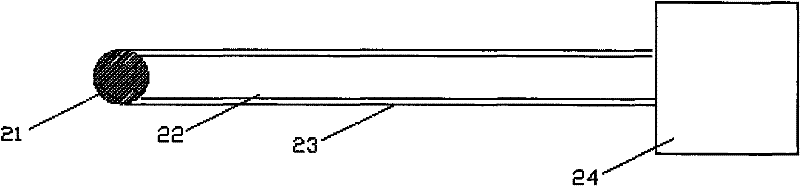

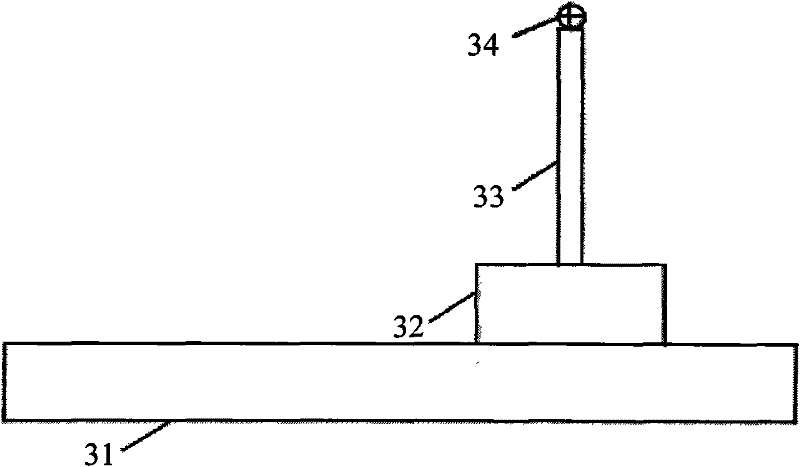

[0016] The test system for the pressure and temperature of the supersonic engine plume field of the present invention includes a Pitot pressure test unit, a thermocouple temperature test unit and a three-dimensional electric control translation platform. The three-dimensional electronically controlled translation platform includes a radial translation module, on which an axial translation module is arranged, a height movement module is arranged on the axial translation module and a test unit installation platform installed on the height movement module, and a pressure test unit is installed on the test unit installation platform. unit and temperature test unit, where figure 1 shows the engine plume pitot pressure test cell structure, figure 2 The temperature test unit structure of the test system of the plume field pressure and temperature of the present invention is illustrated, image 3 The three-dimensional electronically controlled translation stage structure is shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com