Semiconductor module

A semiconductor and chip technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of position shift, difficulty in manufacturing semiconductor modules with high yield, and difficulty in high precision, etc. The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

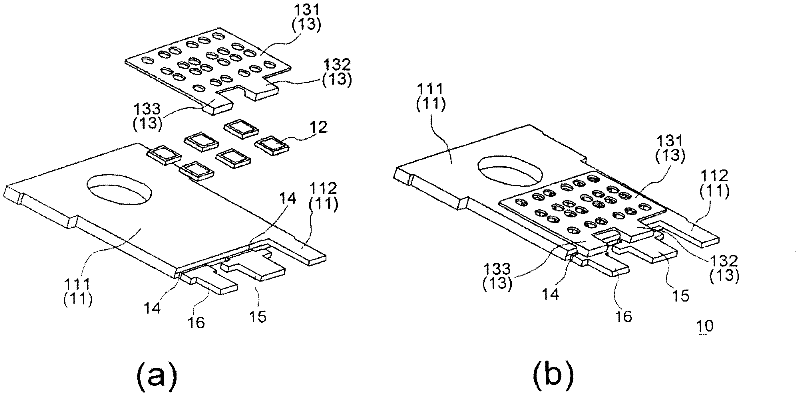

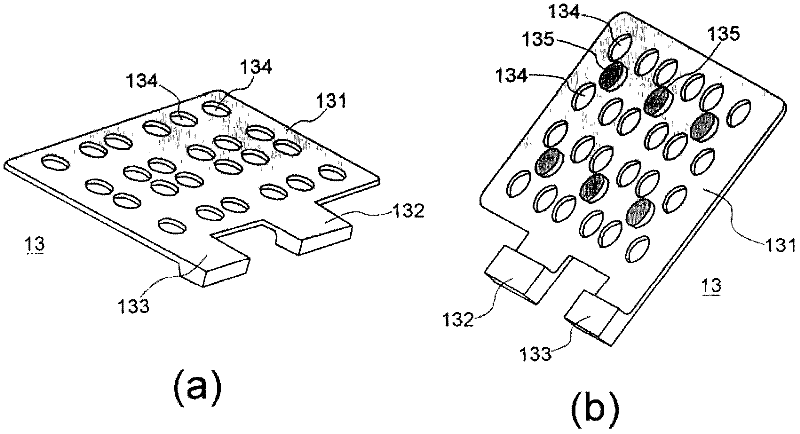

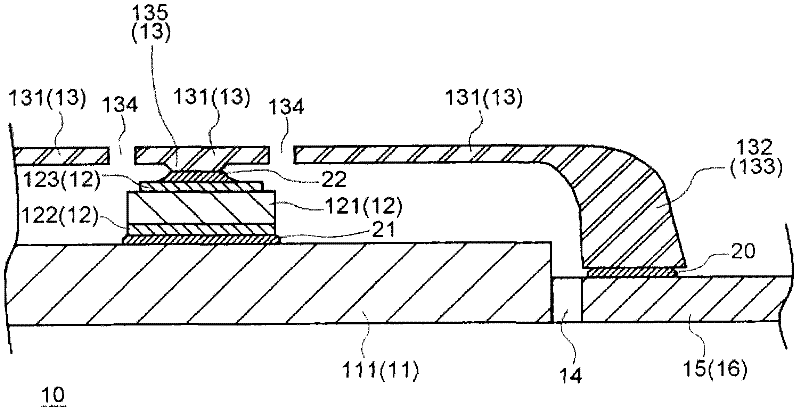

[0045] Hereinafter, the semiconductor module and its manufacturing method according to the embodiment of the present invention will be described. In this semiconductor module, a plurality of semiconductor chips are joined by soldering and mounted on the same lead frame. The mounted semiconductor chips have the same specifications and each has two electrodes (anode electrode, cathode electrode). Among them, one electrode of all the semiconductor chips is connected to the lead frame by solder. The other electrodes of all the semiconductor chips are connected to clip leads provided to cover the upper portions of all the semiconductor chips. With this structure, all the semiconductor chips are connected in parallel, the lead frame side is an electrode of one pole, and the clip lead side is an electrode of the other pole.

[0046] figure 1 It is an exploded perspective view ((a)) and an assembled perspective view ((b)) showing the structure of the semiconductor module 10 . In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com