Shell having effect of pattern with gradient color and manufacturing method for shell

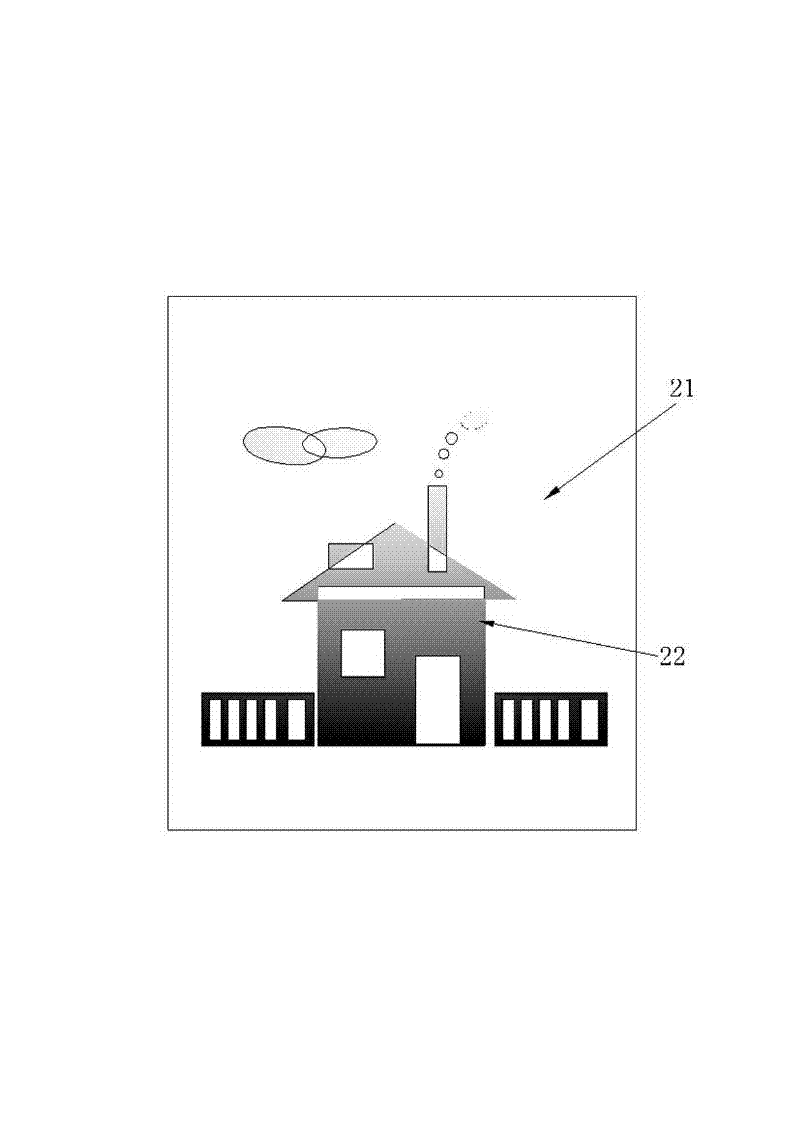

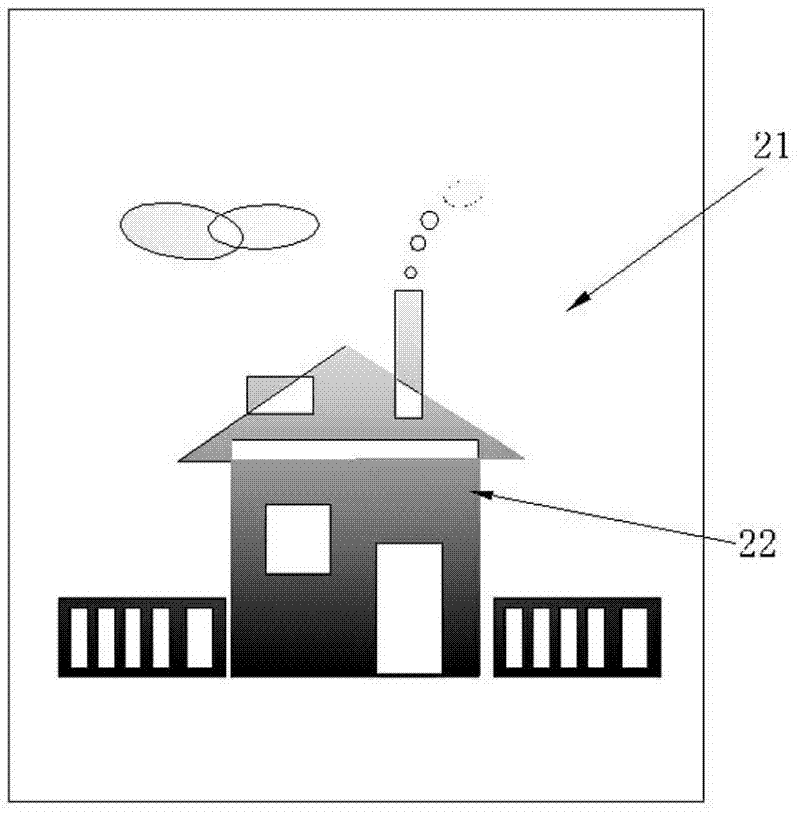

A production method and gradation technology, which are applied to the photoengraving process of the pattern surface, patterns characterized by light projection effects, special patterns, etc. Not easy to fade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

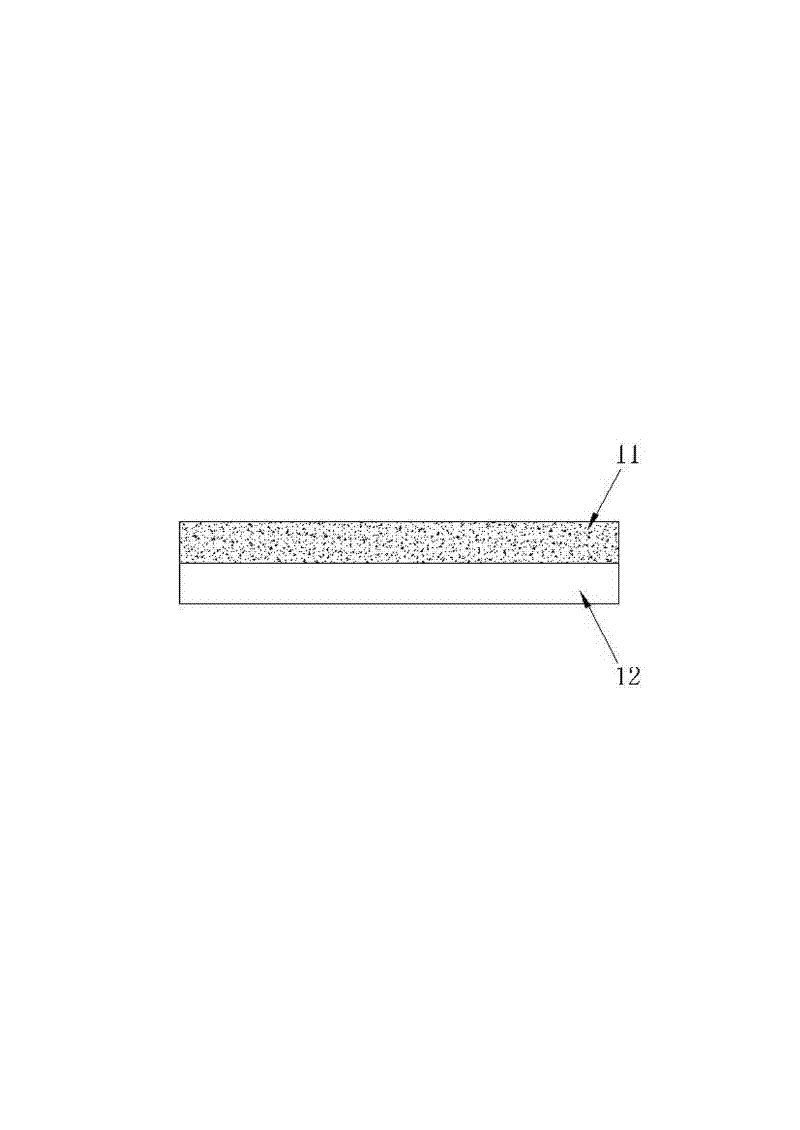

[0037] 1. Exposure and development

[0038] A transparent PC film sheet with a thickness of 0.188 mm and a length and width of 105×148.5 mm is selected, wherein the PC sheet is a film sheet provided by Bayer Company of Germany. The water-resistant photosensitive glue is evenly coated on the first surface of the sheet, and dried naturally at room temperature. The photosensitive glue is a single-component photosensitive glue, and the photosensitive glue adopts the water-resistant W series W-300F provided by Tianling Fine Chemical Co., Ltd. Then paste the patterned film negative on the first surface of the sheet and expose it under ultraviolet rays. The exposure light source is a metal halide lamp (iodine gallium lamp) with a power of 3000 watts. The exposure time depends on the selected photosensitive adhesive and light source. , determine the exposure time is 1-1.5 minutes. Excessive exposure will cause excessive sensitization of the photoresist, and the film will harden, and ...

Embodiment 2

[0050] 1. Exposure and development

[0051] A transparent PC film sheet with a thickness of 0.15 mm and a length and width of 105×148.5 mm is selected, wherein the PC sheet is a film sheet provided by Bayer Company of Germany. The water-resistant photosensitive glue is evenly coated on the first surface of the sheet, and dried naturally at room temperature. The photosensitive glue is a single-component photosensitive glue, and the photosensitive glue adopts the water-resistant W series W-300F provided by Tianling Fine Chemical Co., Ltd. Then paste the patterned film negative on the first surface of the sheet and expose it under ultraviolet rays. The exposure light source is a metal halide lamp (iodine gallium lamp) with a power of 3000 watts. The exposure time depends on the selected photosensitive adhesive and light source. , determine the exposure time is 1-1.5 minutes. Excessive exposure will cause excessive sensitization of the photoresist, and the film will harden, and t...

Embodiment 3

[0063] 1. Exposure and development

[0064] A transparent PET film sheet with a thickness of 0.1 mm and a length and width of 105×148.5 mm is selected, and the PC sheet is a film sheet provided by Bayer Company of Germany. Apply water-resistant photosensitive adhesive evenly on the first surface of the sheet, and dry naturally at room temperature. The photosensitive adhesive is a two-component photosensitive adhesive, and the photosensitive adhesive adopts water-resistant W210 series photosensitive adhesive and photosensitive agent provided by Tianling Company (First dissolve the photosensitive agent in water according to the formula of 1:10 by mass, then mix it in latex which is 5 parts larger than the aqueous solution, stir well, leave it for 1-2 hours, and use it after the bubbles disappear), and then paste the film negative with the pattern on The first surface of the sheet is exposed under ultraviolet light. The exposure light source is a metal halide lamp (iodine gallium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com