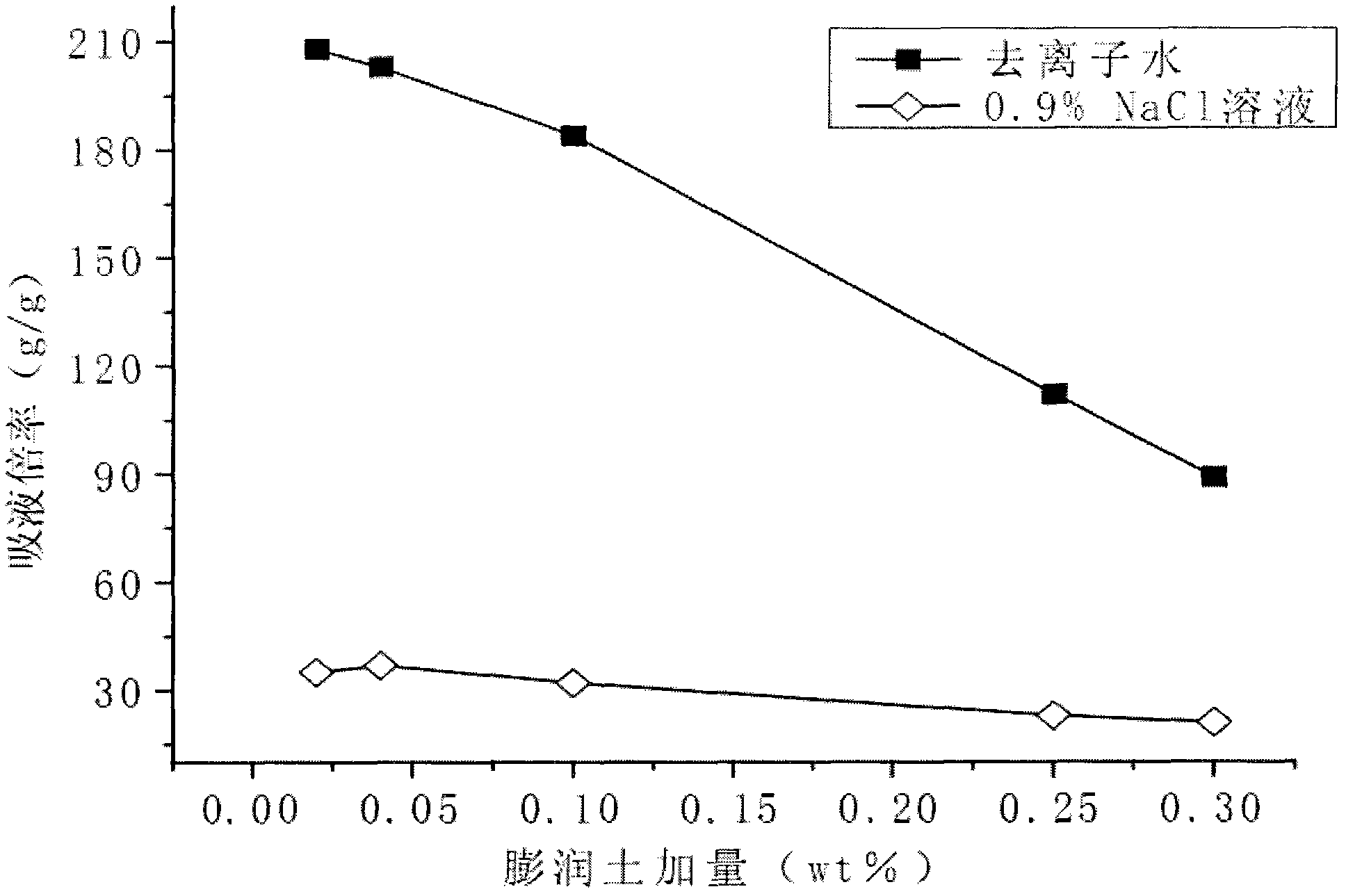

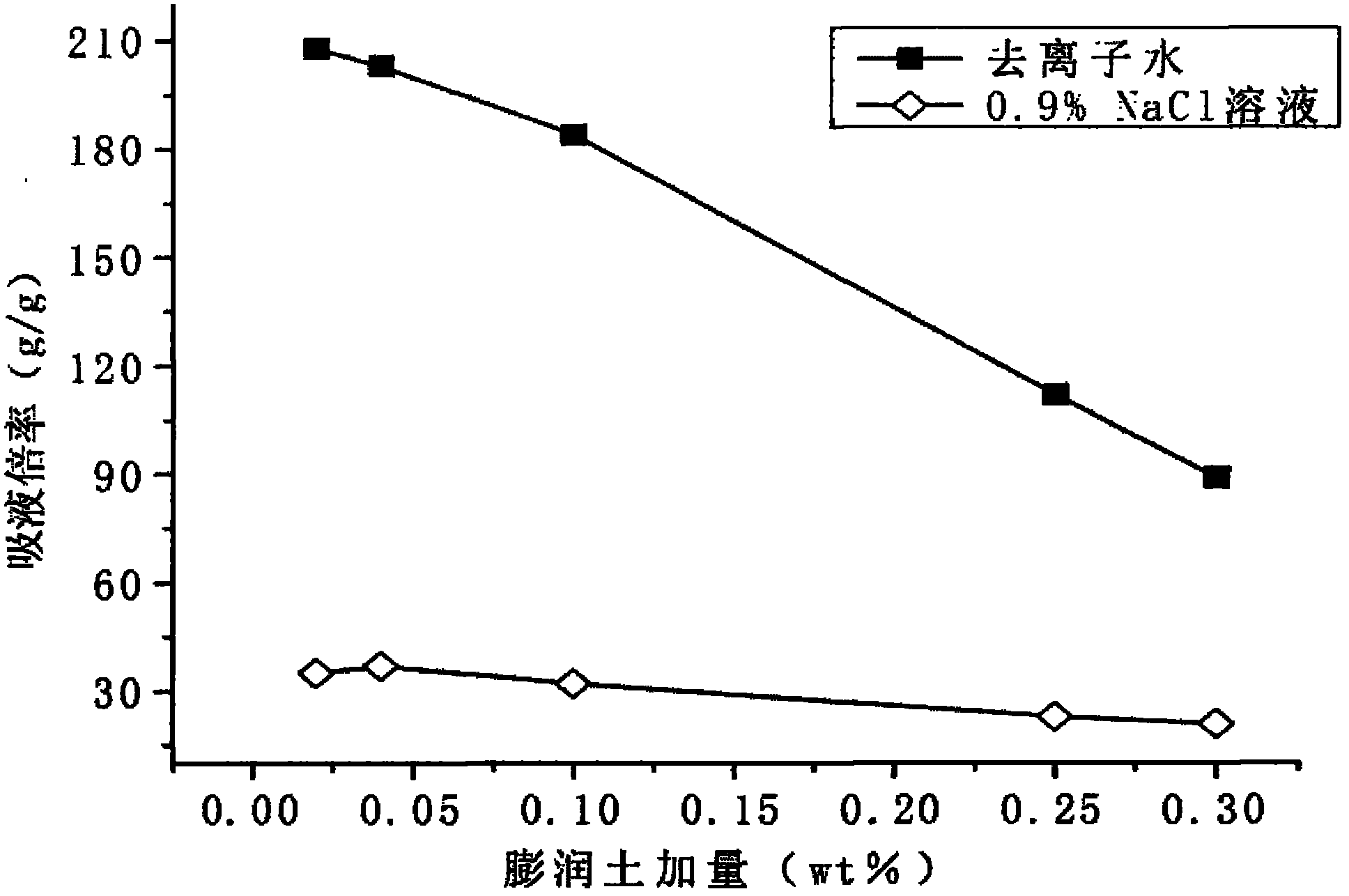

Bentonite dosage controlled synthetic technology for hydrophobic high strength resin

A synthesis process, a technology of bentonite, which is applied in the synthesis process of hydrophobic high-strength resins, can solve the problems of polymer brittleness and reduced tensile strength, and achieve the effects of high synthesis efficiency, lower synthesis cost, and improved liquid absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] A kind of synthetic technique of the hydrophobic type high-strength resin that the present invention relates to controlling the amount of bentonite comprises the following steps:

[0033] (a) Put the sodium-based bentonite in a beaker, add water and stir until the bentonite is fully hydrated and dispersed, and let stand to make it fully hydrated;

[0034] (b) Add acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, hydrophobic monomer, sodium bentonite and a small amount of distilled water into the reaction vessel, and the mass of bentonite accounts for 10% of the total amount of monomers, and slightly heat Stir to dissolve it all;

[0035] (c) After cooling down, add acrylic acid partially neutralized by NaOH, and pass through nitrogen to exhaust oxygen, add initiator and crosslinking agent solution, heat up for pre-reaction, and increase the stirring speed;

[0036] (d) After stirring, transfer the pre-reaction solution into a specific container, continue to pass n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com