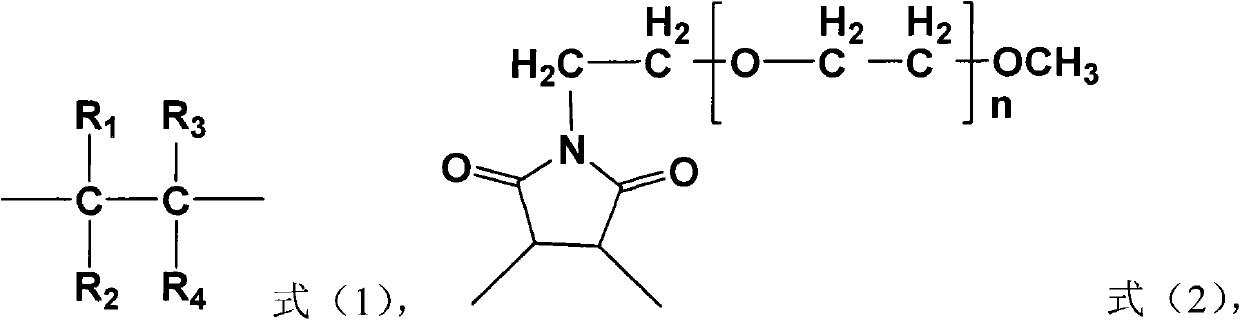

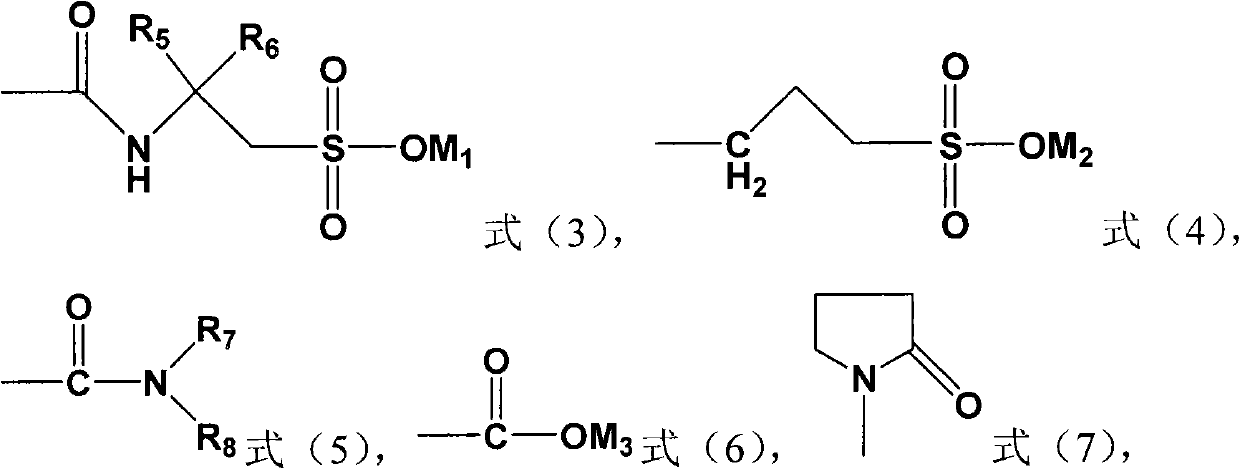

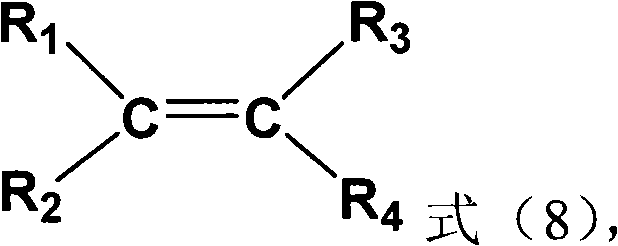

Water-soluble thermo-thickening copolymer, and preparation method and application thereof

A copolymer, water-soluble technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of not easily hydrolyzed, unable to effectively use temperature-resistant and salt-resistant polymer oil displacing agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This example is used to prepare the water-soluble thermally thickening copolymer of the present invention.

[0047] Add 35.1 grams of acrylamide, 25 grams of methoxypolyethylene glycol maleamide (the number average molecular weight is 5000, purchased from Aladdin company) and 150g deionized water, stir until acrylamide and methoxypolyethylene glycol maleamide dissolve completely, adjust the pH with 30% by weight of sodium hydroxide solution to be 9-11, adjust the initial temperature to be 15°C, While stirring, feed nitrogen for 60 minutes to remove dissolved oxygen, add 10 milliliters of 1% by weight of potassium persulfate solution and 10 milliliters of 0.5% by weight of urea solution as an initiator, heat up to 35°C and keep this temperature, and react for 5 hours , to obtain the water-soluble thermal thickening copolymer P1, the viscosity-average molecular weight of the water-soluble thermal thickening copolymer P1 is 9.52×10 6 , wherein the molar content of the acr...

Embodiment 2

[0053] This example is used to prepare the water-soluble thermally thickening copolymer of the present invention.

[0054] Add 50 grams of acrylamide, 10 grams of acrylic acid and 25 grams of methoxypolyethylene glycol maleamide (the number average molecular weight is 5000) in the four-port polymerization reactor equipped with stirrer, thermometer, air guide tube and reflux condenser And 130g deionized water, stir until acrylamide and methoxy polyethylene glycol maleamide are completely dissolved, adjust pH to be 9-10 with 30% by weight of sodium hydroxide solution, adjust initial temperature to be 15 ℃, stirring Simultaneously feed nitrogen for 60 minutes to remove dissolved oxygen, add 10 milliliters of 5% by weight of ammonium persulfate solution as an initiator, heat up to 50° C. and keep this temperature, and react for 6 hours to obtain a water-soluble heat-thickening copolymer P2. The viscosity-average molecular weight of the water-soluble thermal thickening copolymer P2...

Embodiment 3

[0058] This example is used to prepare the water-soluble thermally thickening copolymer of the present invention.

[0059] Add 22 grams of acrylamide, 5 grams of 2-acrylamide-2-methylpropanesulfonic acid (purchased from Shandong Union Chemical Company), 50 grams of methoxypolyethylene glycol maleamide (the number average molecular weight is 5000) and 300 g of deionized water, stirred until acrylamide and methoxypolyethylene glycol maleamide are completely dissolved, and oxidized with 30% by weight of hydrogen The sodium solution is adjusted to pH 10-11, and the initial temperature is adjusted to be 15°C. While stirring, feed nitrogen for 60 minutes to remove dissolved oxygen, add 5 milliliters of 1% by weight V50 solution as an initiator, heat up to 55°C and keep This temperature, reaction 2 hours, obtains water-soluble thermal thickening copolymer P3, the viscosity-average molecular weight of water-soluble thermal thickening copolymer P3 is 7.2 * 10 6 , wherein the molar con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com