Synthesis method of organic silicon modified acrylate copolymer

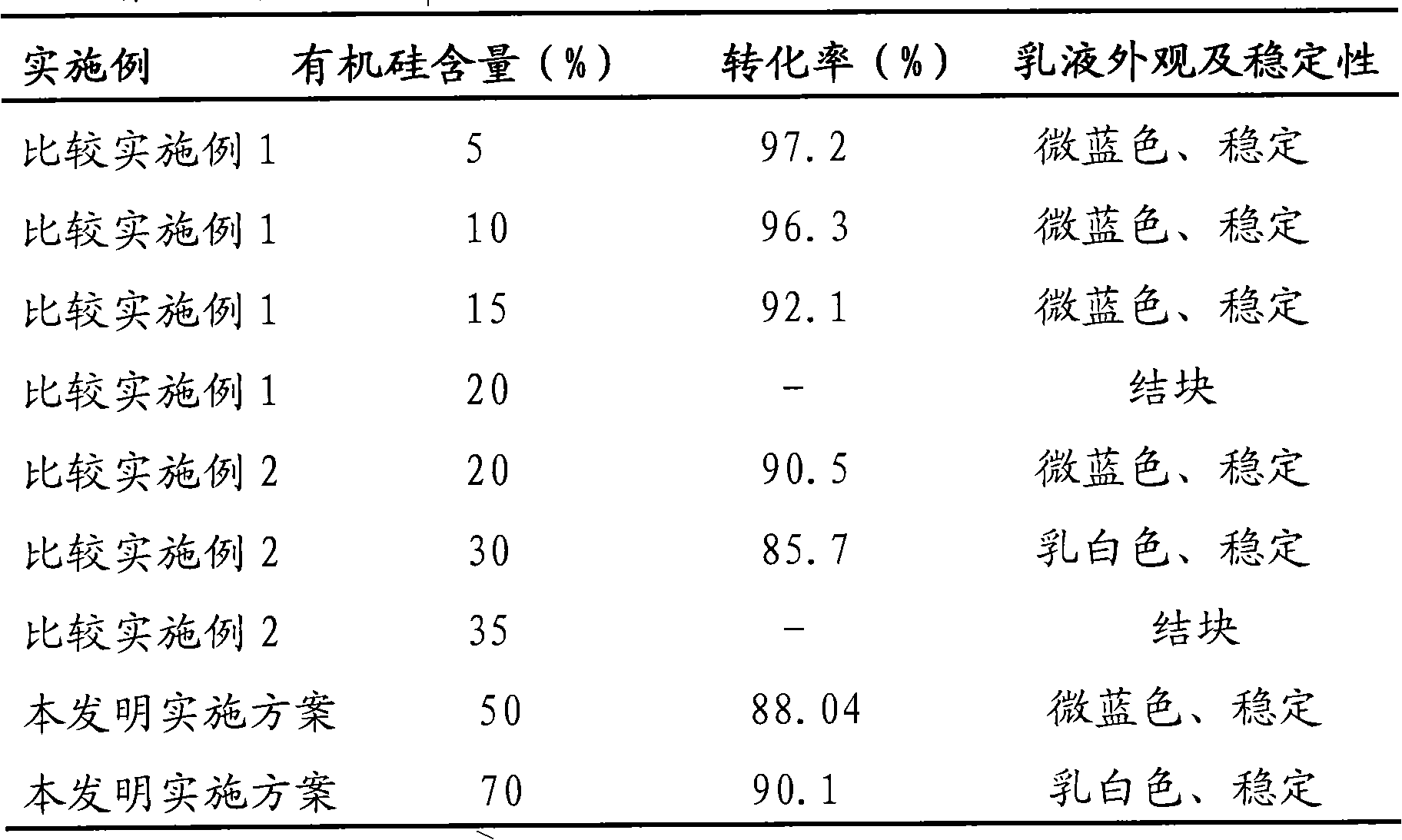

A technology of acrylate and synthesis method, which is applied in the field of synthesis of organosilicon-modified acrylate copolymers, can solve the problems of emulsion instability, poor film-forming property, difficulty in increasing organosilicon content, etc., and achieve good stability and transformation high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

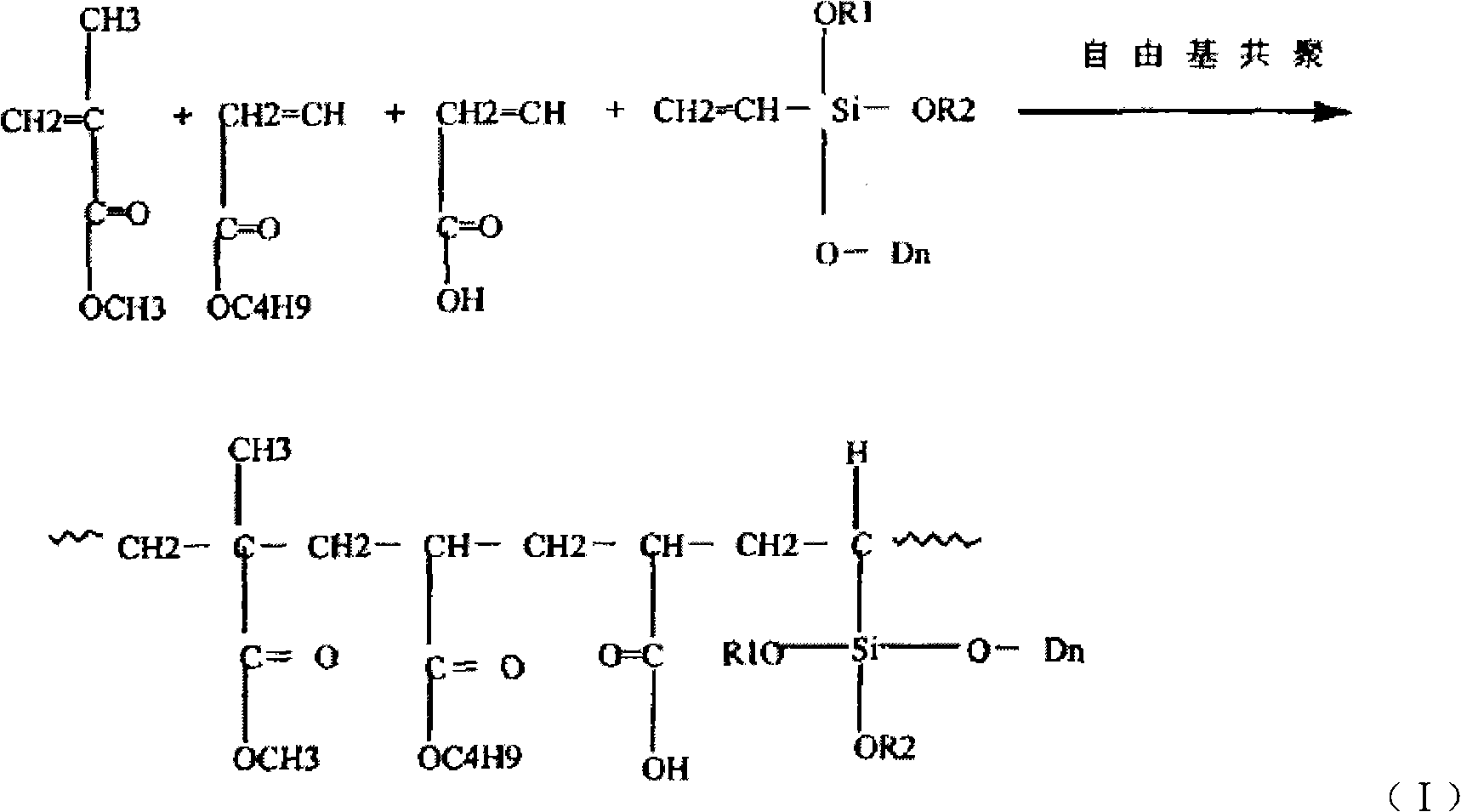

Method used

Image

Examples

specific Embodiment approach

[0020] 1) Synthesis of silicone seed emulsion: adopt the semi-continuous drop method, first measure the emulsifier of the formula amount, deionized water, join in the three-necked flask equipped with agitator, dropping funnel, reflux condenser, adjust the temperature of the water bath to After 75°C, add the catalyst, and start to drop the organosilicon monomer. After the dropwise addition, pass nitrogen gas for 30 minutes: react for 5 hours, cool slowly, adjust the pH value of the system to 7-8 with 10% sodium carbonate solution, and let it stand for 12 hours .

[0021] 2) Graft copolymerization with acrylate monomers: using the same semi-continuous drop method, after adjusting the reaction temperature to 75°C, add acrylate monomers and initiators dropwise to the above seed emulsion, after the addition is complete, Nitrogen was passed for 30 minutes; the reaction was carried out for 5 hours, and the pH value was adjusted to 7-8 with ammonia water. Discharge.

[0022] The org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com