Infrared reflective coating composition

A technology of infrared reflection and composition, applied in the direction of reflection/signal paint, coating, etc., can solve undescribed problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

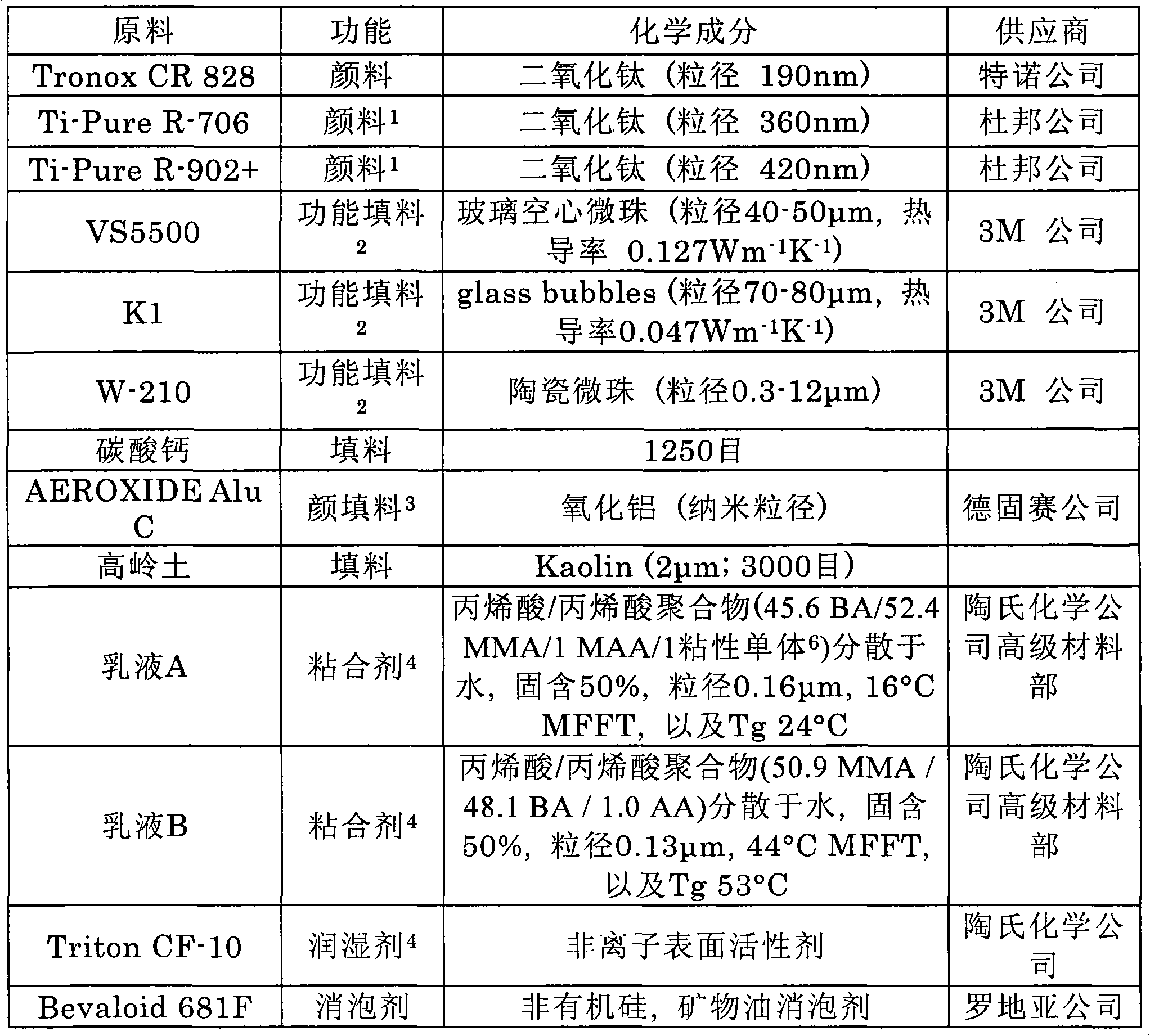

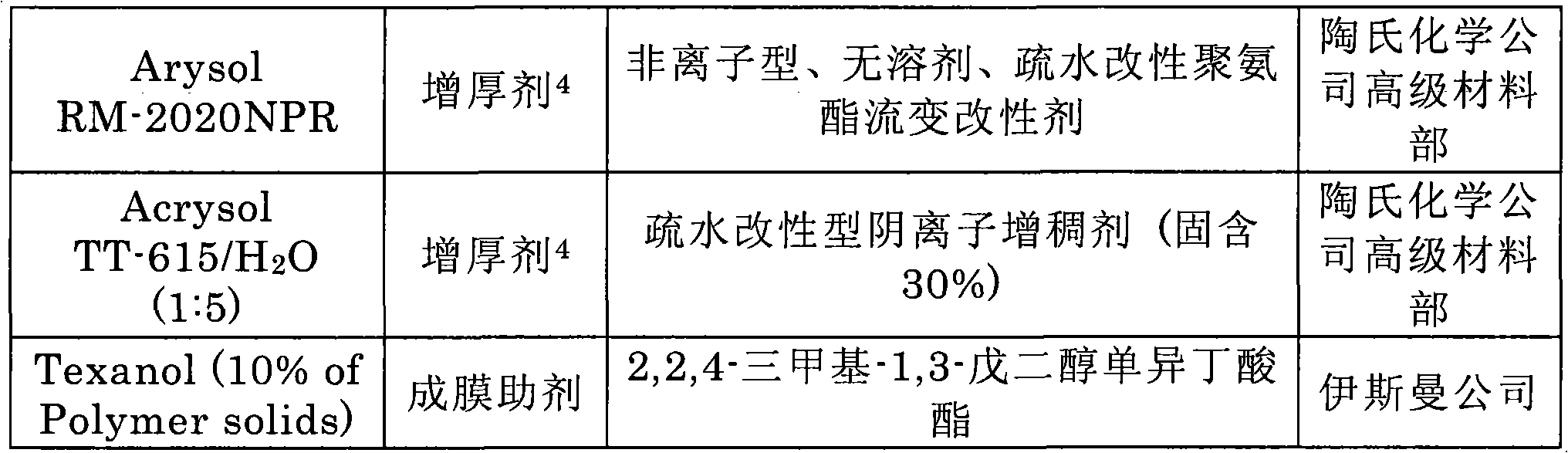

[0088] Preparation of coating composition

[0089] The "beating part" of the composition was obtained by grinding the raw materials listed in Table 2 by a high-speed disperser at a speed of 400 rpm for 30 minutes. After cooling, the "beating part" is sealed and preserved.

[0090] The coating composition was obtained by adding the raw materials in the "Let Down Part" in Table 2 to the "Beating Part". The mixing of these raw materials is accomplished with a mixing paddle under low speed agitation. After preparation, all coating compositions were stored at room temperature.

Embodiment 1-7

[0092] For each reflective coating formulation in Examples 1-7, the four main inorganic components as key technologies are listed in Table 3(a)-(c).

[0093] Table 2 Formula of coating composition

[0094]

[0095] The main inorganic composition of table 3 embodiment and comparative example

[0096] (a)

[0097] (b)

[0098] (c)

[0099] * In Examples 1-5, the glass hollow microspheres are a mixture of VS5500 (having an average particle diameter of 40-50 μm) and K1 (having an average particle diameter of 70-80 μm) in a weight ratio of 6:4 or 7:3

Embodiment 8

[0100] In Examples 8, 10 and 18-19, the glass hollow microspheres are VS5500 (having an average particle diameter of 40-50 μm)

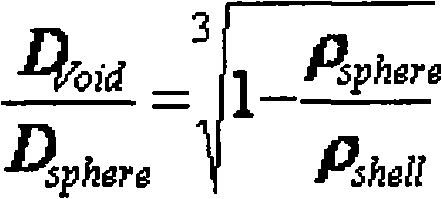

[0101] a The density is 0.38g / cm3, and the hollow part / microsphere diameter ratio is 0.94:1 (3M VS5500) or 0.98:1 (3MK1)

[0102] b The density is 1.5-2.2g / cm3, the hollow part / microsphere diameter ratio is ≤0.68:1, and the average particle size is 1250 mesh or 11μm, obtained from Shenzhen Kongwei Special Materials Co., Ltd. (Shenzhen, Guangdong, China), patent application in China Used in No.200510120766.4

[0103] c The density is 0.7g / cm3, the hollow part / microsphere diameter ratio is 0.88:1, and the average particle size is 50 mesh or 270 μm, from Shenzhen Kongwei Special Materials Co., Ltd., which uses the performance of solar reflectance in Chinese patent application No.200510120766.4 Test Results

[0104] The solar reflectance performance is tested in the total wavelength band of sunlight radiation 300-2500nm, ultraviolet light band 300-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com