Method for forming semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve the problems of high price of platinum metal, increase the difficulty of etching nickel alloy layer, and increase the cost of process manufacturing, so as to strengthen the diffusion barrier, improve the leakage performance of devices, reduce generated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

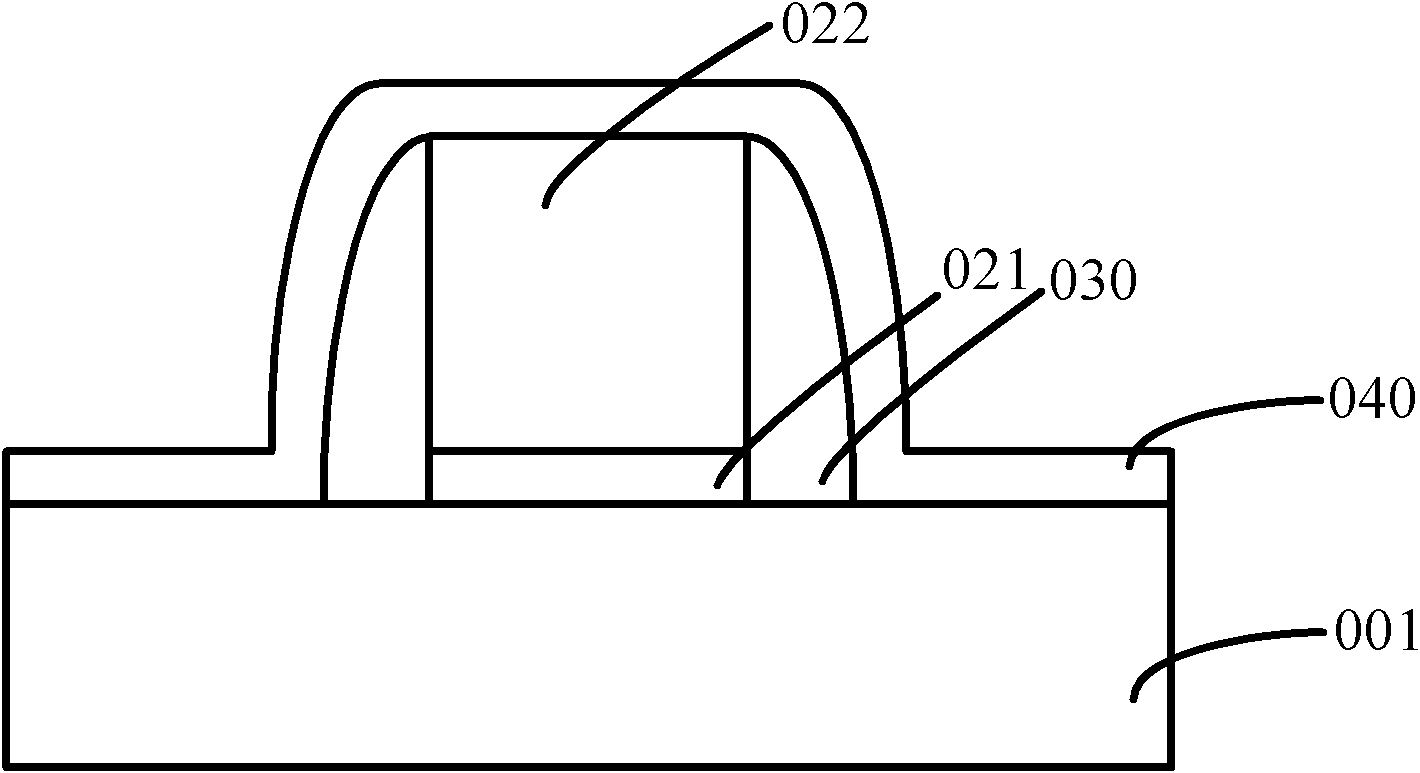

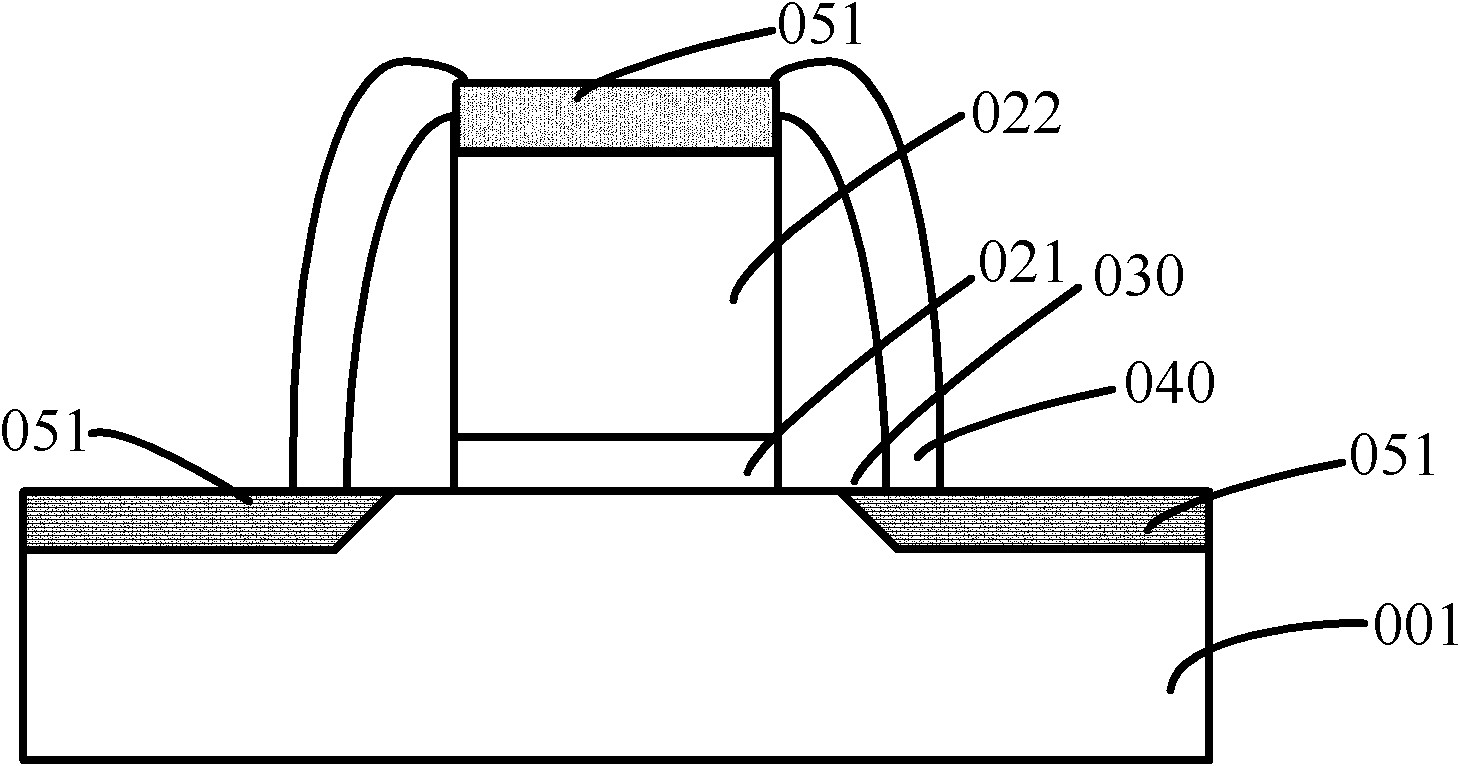

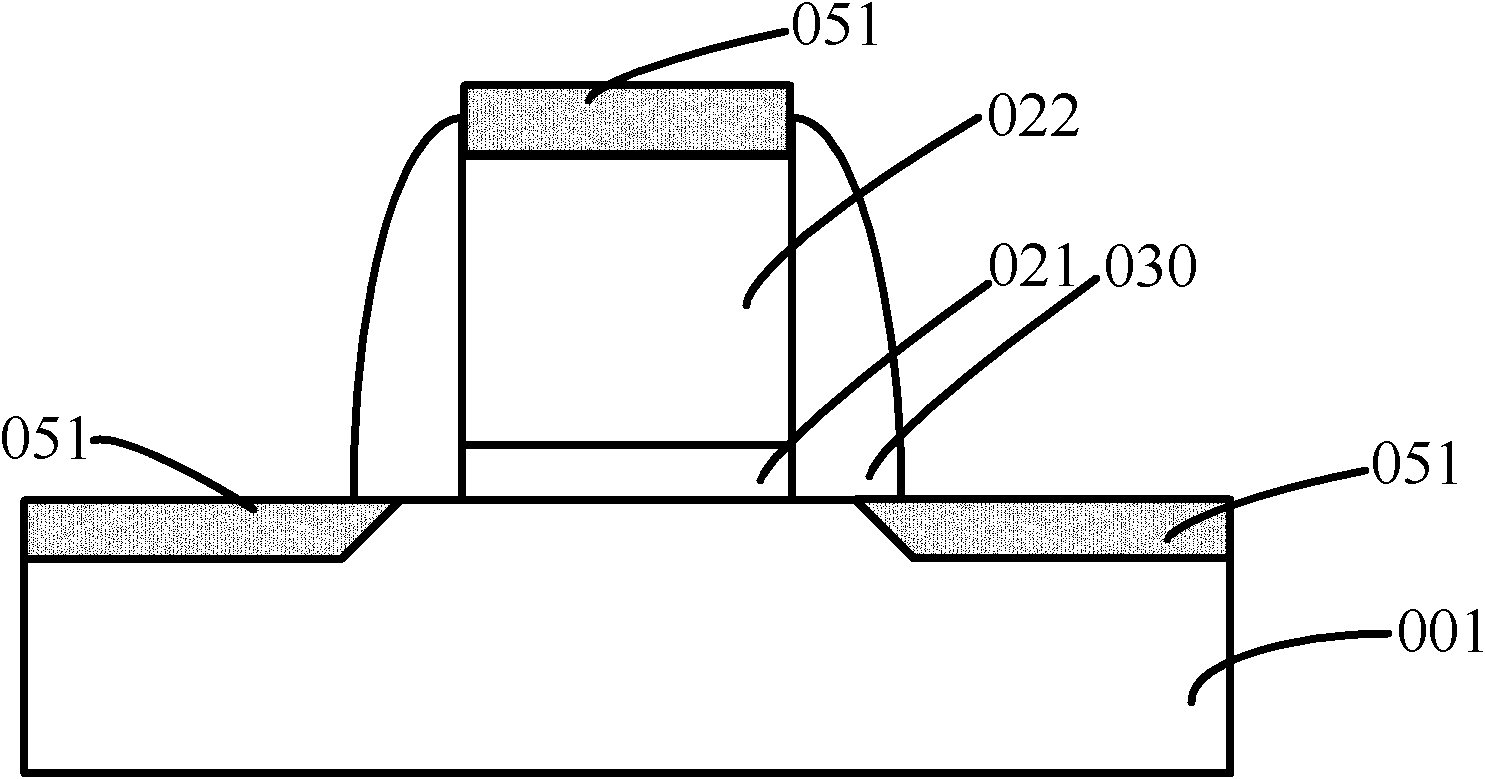

[0029] In the prior art nickel silicide technology, NiSi formed by nickel diffusion 2 The layer will worsen the channel leakage, and increasing the platinum content will cause the cost to rise. Based on the above problems, the inventor conducted a series of experiments, mainly by changing the thickness of the nickel alloy layer, to compare and study the concentration relationship of each metal in the nickel silicide generated by the nickel alloy layer in the substrate. In this experiment, the nickel alloy layer is an alloy layer of nickel and platinum.

[0030] Such as Figure 5 As shown, it is a schematic diagram of the concentration distribution of nickel in the nickel silicide layer in the substrate. The abscissa represents the depth of the substrate, and the ordinate represents the concentration of nickel contained in the position corresponding to the depth of the substrate. Such as Image 6 As shown, it is a schematic diagram of the concentration distribution of platinum in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com