Film for semiconductor and semiconductor device manufacturing method

A technology of semiconductor and supporting film, which is applied in semiconductor/solid-state device manufacturing, semiconductor device, transportation and packaging, etc. It can solve problems such as cracks and defects in semiconductor components, and achieve high manufacturing yield, high reliability, and anti-pickup properties Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

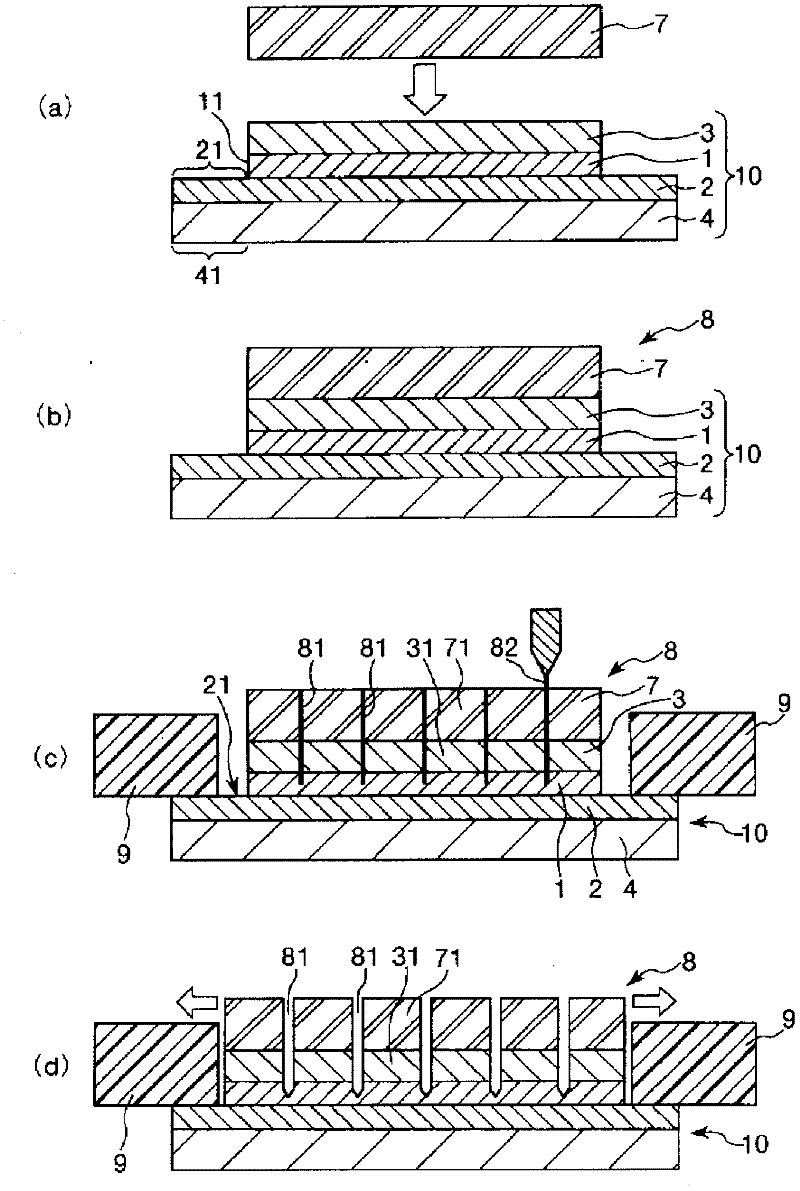

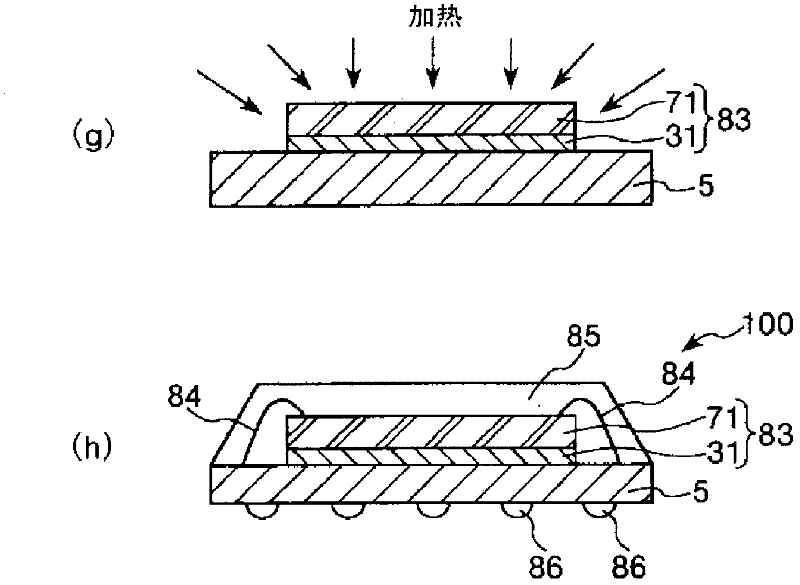

[0050] Figure 1 to Figure 3 It is a figure (longitudinal cross-sectional view) for explaining the first embodiment of the film for semiconductor of the present invention and the manufacturing method of the semiconductor device of the present invention; Figure 4 It is a figure for demonstrating the manufacturing method of the film for semiconductors of this invention. Additionally, in the description below, the Figure 1 to Figure 4 The upper side is called "upper" and the lower side is called "lower".

[0051] [Film for semiconductor]

[0052] figure 1 The film 10 for a semiconductor shown in has a support film 4 , a first adhesive layer 1 , a second adhesive layer 2 , and an adhesive layer 3 . More specifically, the film 10 for a semiconductor is formed by sequentially laminating the second adhesive layer 2 , the first adhesive layer 1 , and the adhesive layer 3 on the support film 4 .

[0053] Such as figure 1 As shown in (a), the above-mentioned semiconductor film...

no. 2 approach

[0224] Next, a second embodiment of the film for a semiconductor of the present invention and the method of manufacturing a semiconductor device of the present invention will be described.

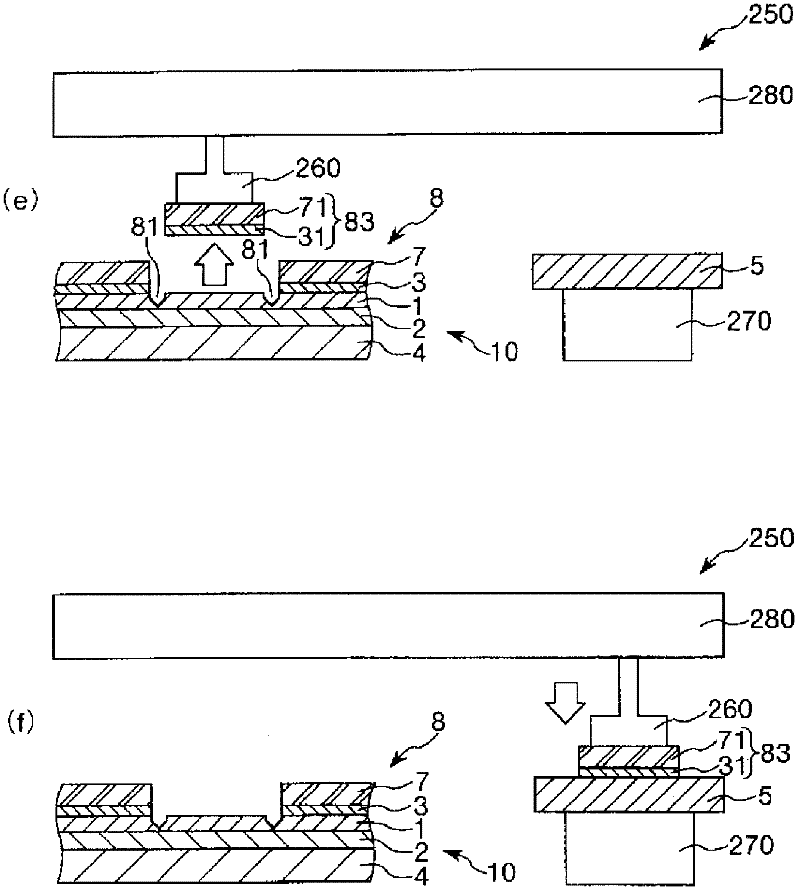

[0225] Figure 5 It is a figure (longitudinal sectional view) for demonstrating the 2nd Embodiment of the film for semiconductors of this invention, and the manufacturing method of the semiconductor device of this invention. Additionally, in the description below, the Figure 5 The upper side is called "upper" and the lower side is called "lower".

[0226] The second embodiment will be described below, but the description will focus on the parts different from the first embodiment, and the description of the same matters will be omitted. In addition, in Figure 5 In the same configuration as the first embodiment, the above-mentioned figure 1 The same notation as described in .

[0227] The semiconductor film 10 ′ in this embodiment is the same as that of the above-mentioned first emb...

Embodiment 1

[0247] Formation of the first adhesive layer

[0248] 100 parts by weight of a copolymer with a weight average molecular weight of 300,000 obtained by copolymerizing 30% by weight of 2-ethylhexyl acrylate and 70% by weight of vinyl acetate, 45 parts by weight of a pentafunctional acrylate monomer with a molecular weight of 700 , 5 parts by weight of 2,2-dimethoxy-2-phenylacetophenone and 3 parts by weight of toluene diisocyanate (CORONET T-100, Nippon Polyurethane Industry Co., Ltd. ) production) was applied to a polyester film having a thickness of 38 μm after peeling treatment so that the thickness after drying would be 10 μm, and then dried at 80° C. for 5 minutes. Then, the obtained coating film was irradiated with 500mJ / cm 2 Ultraviolet rays form a film of a first adhesive layer on a polyester film.

[0249] In addition, the Shore D hardness of the obtained first adhesive layer was 40.

[0250] Formation of the second adhesive layer

[0251] 100 parts by weight of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com