Portable assembly precision joint cutting processing device

A processing device and portable technology, applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of unfavorable maintenance of machine tools, high price and high cost, and achieve the effect of uncomplicated combination principle, guaranteed processing accuracy and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

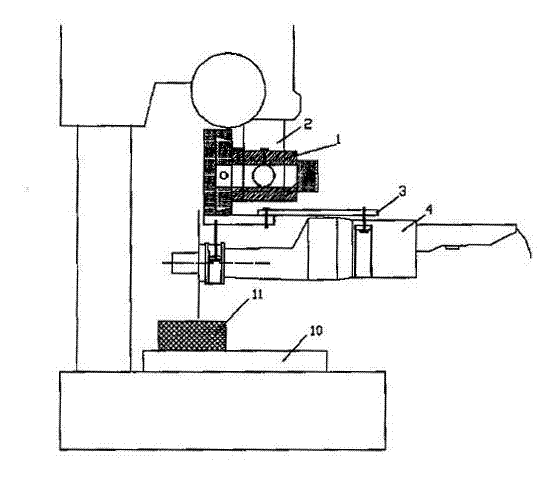

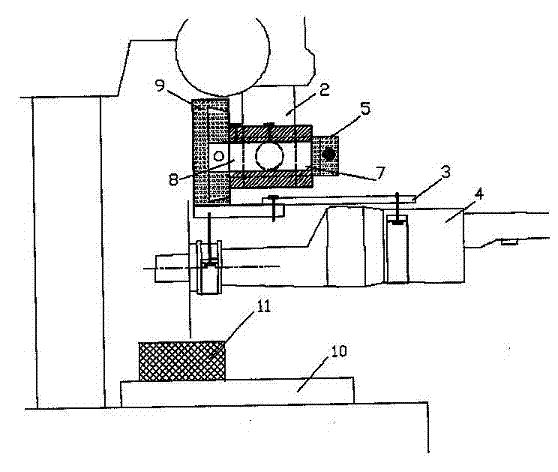

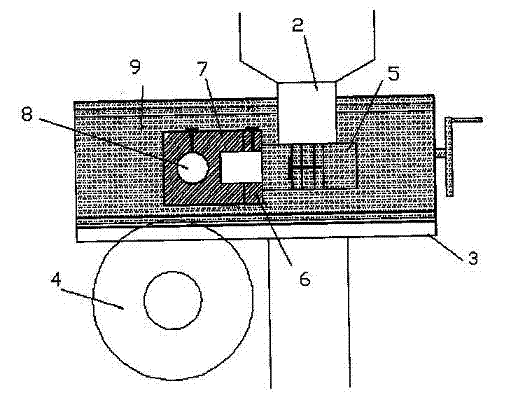

[0016] Fig. 1 is an overall schematic diagram of the assembled light-duty universal slitting precision machining device 1 of the present invention assembled on a drilling and milling machine. The combined device 1 is the overall structure of the universal slitting precision machining device of the present invention, including a metal snap ring 5, a rotating shaft Seat 7, fixed shaft seat 6 and supporting rotating shaft 8 and a small workbench 9 of one-way walking. Among them, the metal snap ring 5 is fixed on the front end of the rotating shaft seat 7, the fixed shaft seat 6 is between the metal snap ring 5 and the rotating shaft seat 7, the supporting rotating shaft 8 is at the rear of the rotating shaft seat 7, and the small workbench 9 is matched with the matching The rotating shafts 8 are connected together and fixed on the rotating shaft seat 7 . The test piece 11 is located on the lower workbench 10 of the drilling and milling machine.

[0017] Figure 1 shows the overal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com