Dielectric substrate manufacturing method

A medium substrate, hydrothermal technology, applied in chemical instruments and methods, printed circuit manufacturing, lamination, etc., can solve the problems of human injury, asbestos short fibers easily falling out, etc., to avoid injury, easy processing, and enhance hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

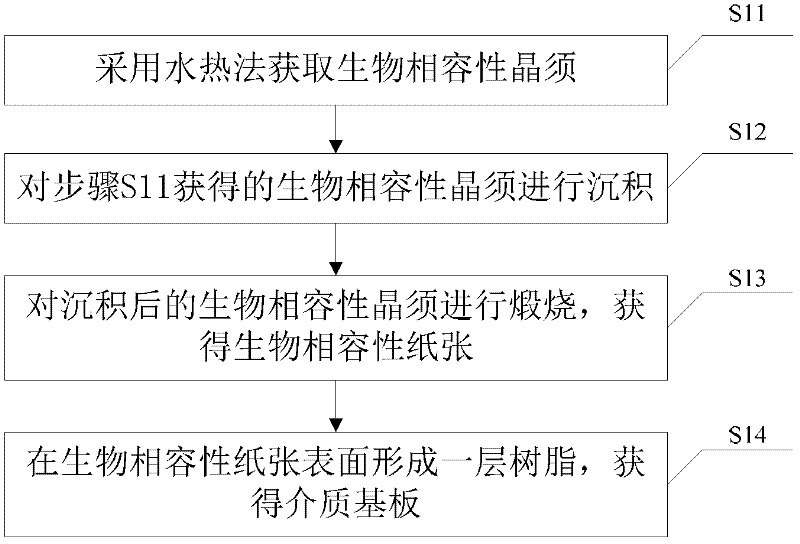

[0018] see figure 1 , is a flow chart of a method for preparing a dielectric substrate provided in Embodiment 1 of the present invention, and the method includes:

[0019] S11: Obtaining biocompatible whiskers by hydrothermal method.

[0020] Among them, the biocompatible whiskers can be AIO(OH) or Ca 10 (PO 4 ) 6 (OH) 2 .

[0021] For example, with Al(OH) 3 Colloids are used as precursors for Al(OH) 3 The colloid was hydrothermally treated to transform it into boehmite AIO(OH).

[0022] S12: depositing the biocompatible whiskers obtained in step S11.

[0023] For example, AIO(OH) is deposited so that AIO(OH) forms a sheet.

[0024] S13: Calcining the deposited biocompatible whiskers to obtain biocompatible paper.

[0025] For example, calcination of flake-shaped AIO(OH) obtained after deposition under normal pressure conditions yields α-Al 2 o 3 Whisker paper.

[0026] S14: forming a layer of resin on the surface of the biocompatible paper to obtain a medium subs...

Embodiment 2

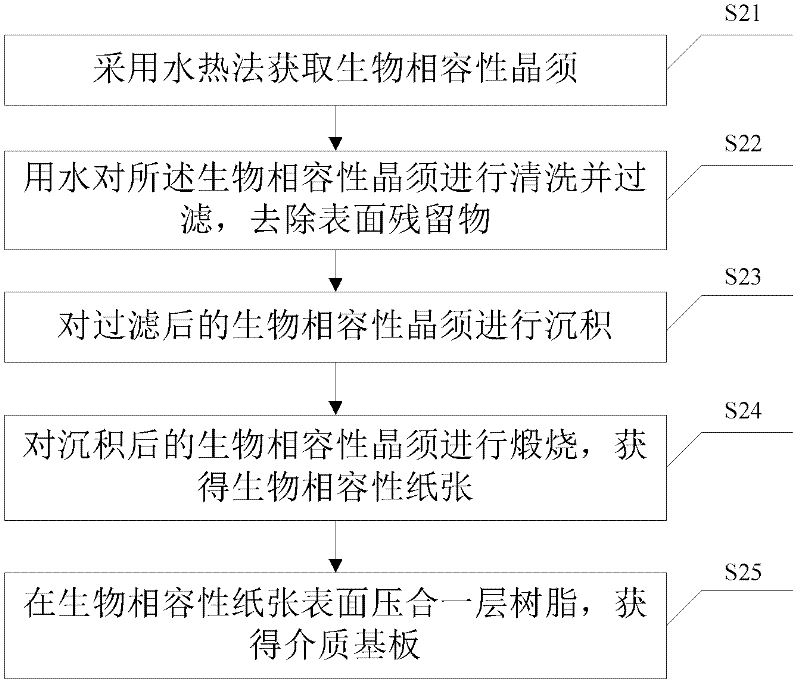

[0030] see figure 2 , is a flowchart of a method for preparing a dielectric substrate provided in Embodiment 2 of the present invention, and the method includes:

[0031] S21: Obtaining biocompatible whiskers by a hydrothermal method.

[0032] Among them, the biocompatible whiskers can be AIO(OH) or Ca 10 (PO 4 ) 6 (OH) 2 .

[0033] For example, with Al(OH) 3 Colloids are used as precursors for Al(OH) 3 The colloid was hydrothermally treated to transform it into boehmite AIO(OH).

[0034] S22: Wash and filter the biocompatible whiskers with water to remove surface residues.

[0035] Wherein, the surface residues of the biocompatible whiskers are ions or molecules. For example, to remove ions or molecules from the surface of AIO(OH).

[0036] S23: depositing the filtered biocompatible whiskers.

[0037] For example, AIO(OH) is deposited so that AIO(OH) forms a sheet.

[0038] S24: Calcining the deposited biocompatible whiskers to obtain biocompatible paper.

[003...

Embodiment 3

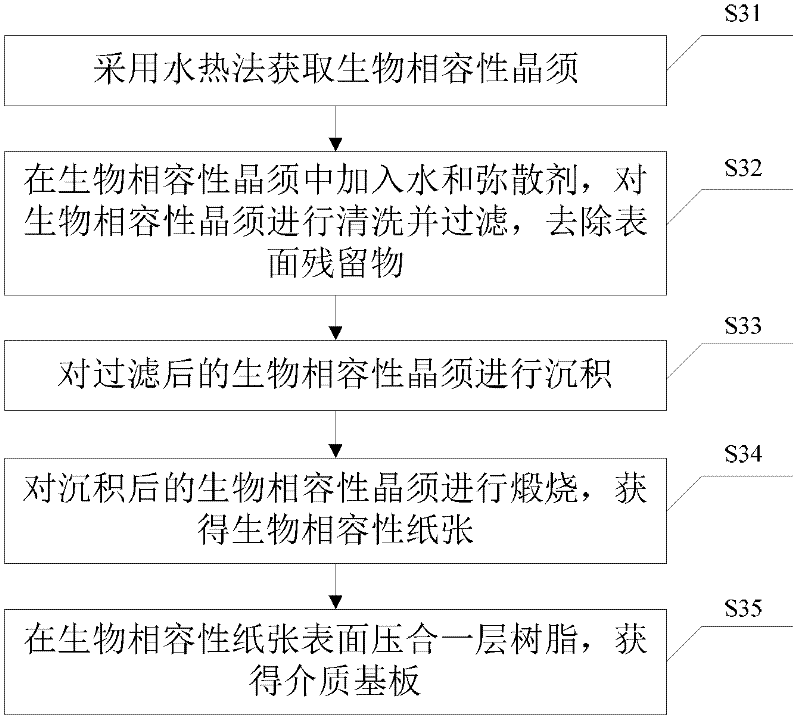

[0044] see image 3 , is a flowchart of a method for preparing a dielectric substrate provided in Embodiment 3 of the present invention, and the method includes:

[0045] S31: Obtaining biocompatible whiskers by a hydrothermal method.

[0046] Among them, the biocompatible whiskers can be AIO(OH) or Ca 10 (PO 4 ) 6 (OH) 2 .

[0047] For example, with Al(OH) 3 Colloids are used as precursors for Al(OH) 3 The colloid was hydrothermally treated to transform it into boehmite AIO(OH).

[0048] S32: adding water and a dispersant to the biocompatible whiskers, cleaning and filtering the biocompatible whiskers, and removing surface residues.

[0049] Wherein, the surface residues of the biocompatible whiskers are ions or molecules. For example, to remove ions or molecules from the surface of AIO(OH).

[0050] S33: depositing the filtered biocompatible whiskers.

[0051] For example, AIO(OH) is deposited so that AIO(OH) forms a sheet.

[0052] S34: Calcining the deposited b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com