Method for drilling horizontal well with super-short radius

An ultra-short-radius, horizontal well technology, applied in liquid/gas jet drilling, directional drilling, wellbore/well components, etc., can solve the problem of limited energy of the jet drill bit, and improve single well production and recovery, Improve the permeability and porosity, which is beneficial to the effect of carrying rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

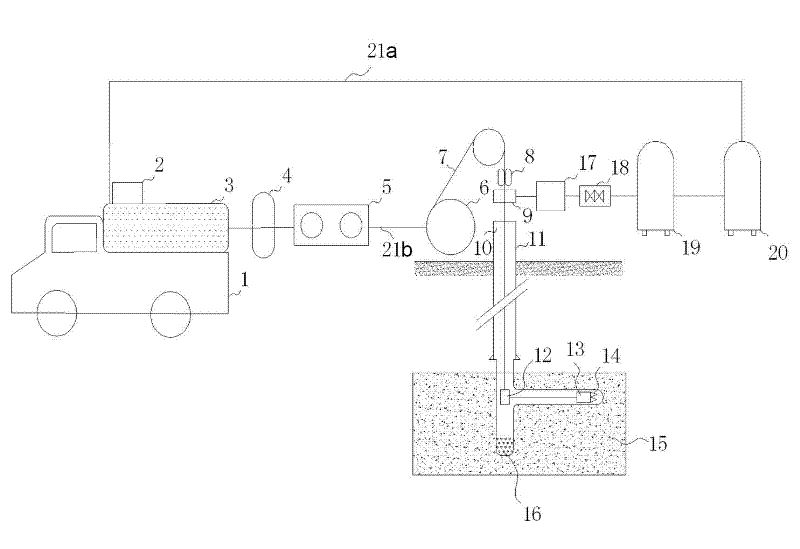

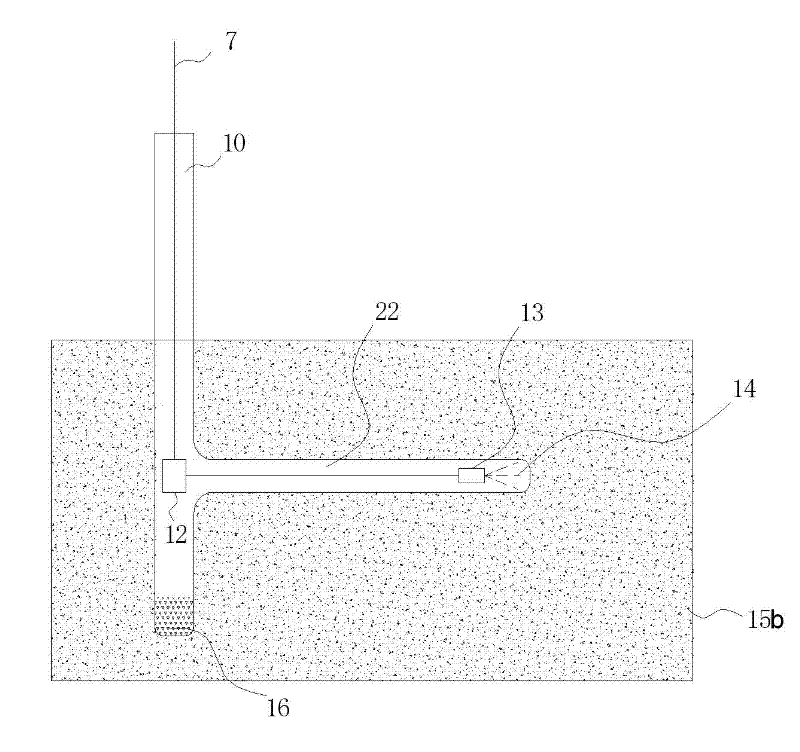

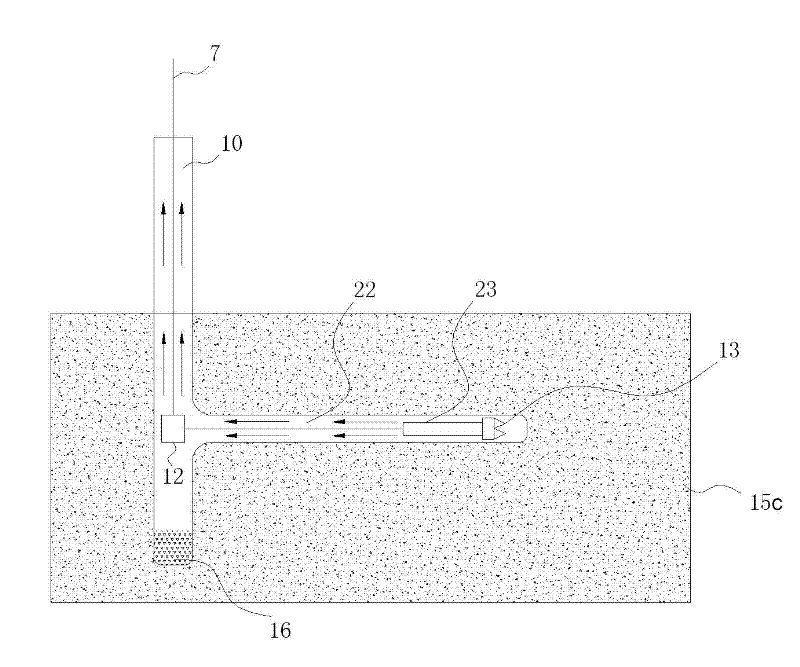

Method used

Image

Examples

Embodiment 1

[0044] Using supercritical CO 2 Fluid-assisted coiled tubing is used to drill ultra-short radius horizontal wells in Mancos shale, and compared with water fluid drilling in Mancos shale, the conditions are shown in Table 1:

[0045] Table 1 Threshold pressure of jet rock breaking

[0046]

[0047] Image 6 It is a comparison result diagram of jet drilling using drilling equipment with a power of 100kw and a diameter of 50mm. The results show that using supercritical CO in the Mancos shale 2 It is 3.3 times the drilling speed of water, and the specific energy SE required for rock breaking (the specific energy SE is the ratio of hydraulic and mechanical energy required for rock breaking to the volume of broken and peeled rock) is only 20% of that of hydraulic drilling. When the pressure is lower than 124MPa, the water jet cannot break the rock, and the supercritical CO 2 The effective pressure of jet rock breaking is as low as 55MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com