Method for hydrorefining petroleum wax

A technology for hydrorefining and petroleum wax, which is applied in petroleum wax refining and other directions, can solve problems such as unsatisfactory refining effect, and achieve the effects of good hydrogenation activity and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

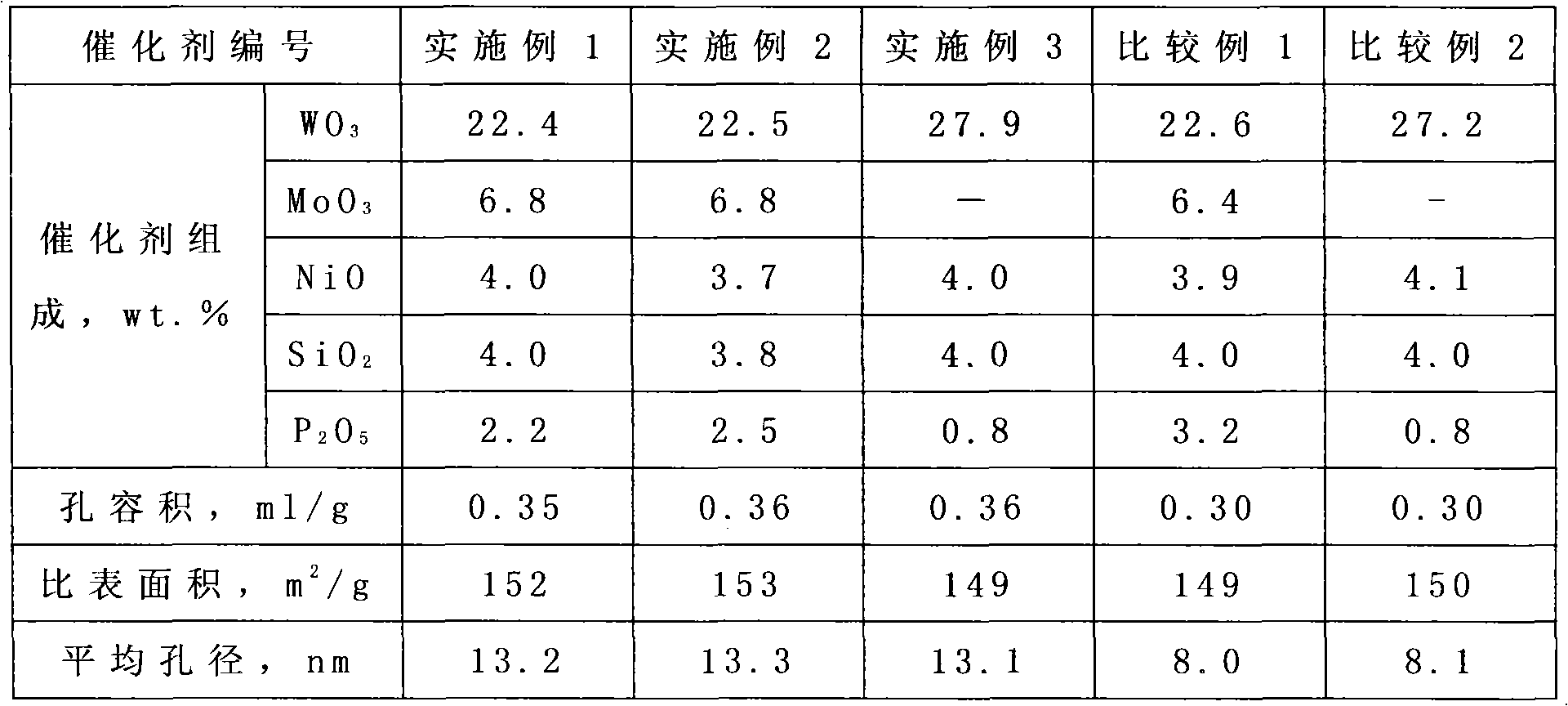

Examples

Embodiment 1

[0022] (1)Al 2 o 3 Preparation of vector

[0023] (a) Macroporous Al with weak surface acidity 2 o 3 preparation of

[0024] Weigh 500g of pseudo-boehmite powder, 15g of Tianqing powder, 15g of citric acid, 50g of fatty alcohol ether phosphate, 350ml of dilute nitric acid of 3wt.% to 5wt.%, knead evenly, dry at 110°C, and roast at 750°C under air Processing, cooling and grinding into >150 mesh powder for later use.

[0025] (b) Weigh 1000g of pseudo-boehmite powder, add the macroporous Al prepared by (a) 2 o 3 300g, 30g Tianqing powder, 30g citric acid, 100g silica sol (SiO 2 concentration of 30wt.%), 700ml of dilute nitric acid of 3wt.%~5wt.%, kneaded evenly, extruded with extruder, dried at 110°C, and roasted at 600°C under air to obtain Al 2 o 3 carrier.

[0026] (2) Preparation of W-Mo-Ni-P impregnation solution

[0027] Configure 1000ml solution, weigh 125g molybdenum trioxide (industrial grade) and 60g basic nickel carbonate (industrial grade) and join in 600m...

Embodiment 2

[0031] (1)Al 2 o 3 Preparation of vector

[0032] (a) Macroporous Al with weak surface acidity 2 o 3 preparation of

[0033] Weigh 500g of pseudo-boehmite powder, 15g of Tianqing powder, 15g of citric acid, 60g of polyol phosphate, 350ml of dilute nitric acid of 3wt.% to 5wt.%, knead evenly, dry at 110°C, and roast at 800°C under air , cooled and ground into >150 mesh powder for later use.

[0034] (b) Weigh 1000g of pseudo-boehmite powder, add the macroporous Al prepared by (a) 2 o 3 350g, 30g Tianqing powder, 30g citric acid, 110g silica sol (SiO 2 concentration of 30%), 730ml of dilute nitric acid of 3% to 5%, kneaded evenly, extruded with extruder, dried at 110°C, and roasted at 600°C under air to obtain Al 2 o 3 carrier.

[0035] (2) Preparation of W-Mo-Ni-P impregnation solution

[0036] With embodiment 1 (2).

[0037] (3) Preparation of W-Mo-Ni catalyst

[0038] Weigh 500g Al2 o 3 For the carrier, measure 360ml of the solution prepared in step (2), impregn...

Embodiment 3

[0040] (1)Al 2 o 3 Preparation of vector

[0041] With embodiment 1 (1).

[0042] (2) Preparation of W-Ni catalyst.

[0043] Weigh 500g Al 2 o 3 Carrier, measure the aqueous solution of 375ml ammonium metatungstate and nickel nitrate (wherein WO 3 The concentration is 70g / 100ml; the concentration of NiO is 20g / 100ml) equal volume impregnation for 30min, drying at 110°C, and then roasting at 460°C to obtain the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com