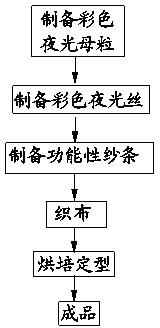

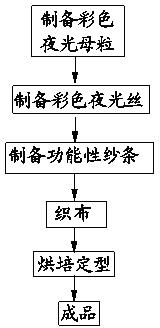

Processing process of colored noctilucent fabric

A processing technology and color technology, applied in the direction of adding pigments, textiles, fabrics, etc. to the spinning solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The specific preparation process of the fabric is as follows:

[0021] a) Preparation of colored luminous masterbatch, the preparation process of the colored luminous masterbatch:

[0022] 1) To prepare a rare earth aluminate solution, add 6% strontium nitrate, 12% aluminum nitrate, 0.04% europium oxide, 0.03% cerium oxide, and 0.02% dysprosium oxide to a nitric acid solution with a concentration of 45% and a content of 60%. Stir evenly and dilute with water to prepare a rare earth aluminate solution with a concentration of 15%;

[0023] 2) To prepare photosensitive gel, first, take 75% rare earth aluminate solution, add 15% ammonium bicarbonate solution, 5% adhesive, 5% active agent, stir evenly for 3 hours, and control the temperature at 90°C , and then, wash with deionized water for 10 minutes, and finally, dry in a dryer to obtain a photosensitive gel, and the drying temperature is controlled at 100°C;

[0024] 3) Prepare the color gel matrix, mix the photosensiti...

Embodiment 2

[0031] The specific preparation process of the fabric is as follows:

[0032] a) Preparation of colored luminous masterbatch, the preparation process of the colored luminous masterbatch:

[0033] 1) To prepare a rare earth aluminate solution, add 6% strontium nitrate, 15% aluminum nitrate, 0.02% europium oxide, 0.03% cerium oxide, and 0.04% dysprosium oxide to a nitric acid solution with a concentration of 45% and a content of 82%. Stir evenly and dilute with water to prepare a 20% rare earth aluminate solution;

[0034] 2) To prepare photosensitive gel, firstly, take 73% rare earth aluminate solution, add 15% ammonium bicarbonate solution, 6% adhesive, 6% active agent, stir evenly for 4 hours, and control the temperature at 90°C , then, wash with deionized water for 10 minutes, and finally, dry in a dryer to obtain a photosensitive gel, and the drying temperature is controlled at 110°C;

[0035] 3) Prepare the color gel matrix, mix the photosensitive gel, inorganic transpar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com