Power cable with built-in detection optical fiber

A power cable and detection optical fiber technology, which is applied to power cables with shielding layers/conductive layers, communication cables, cables, etc., can solve problems such as excessive heating of power cables, shortened life of cable insulation layers, and limited application range, etc., to achieve extended Effects of service life, increased detection distance, and increased dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

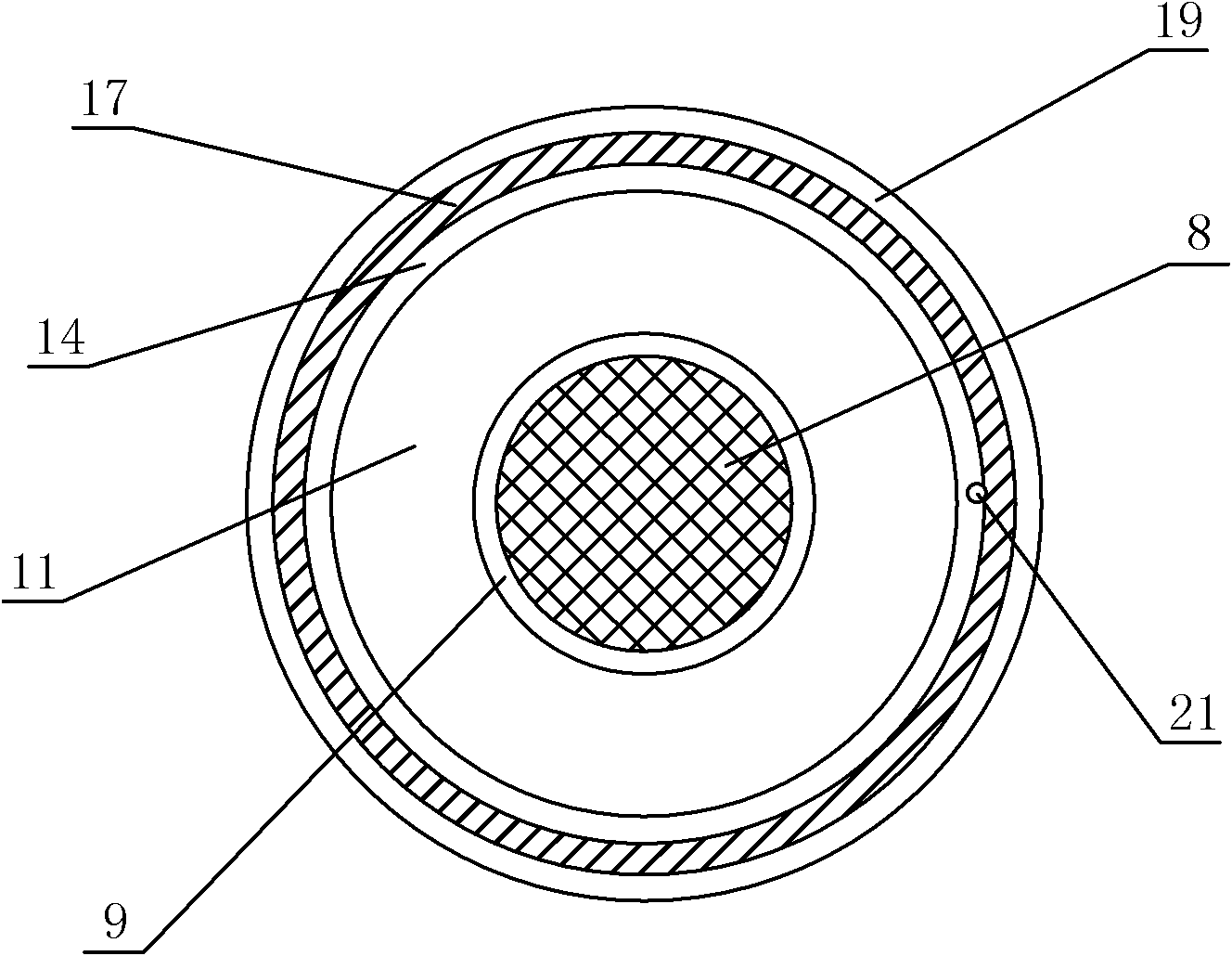

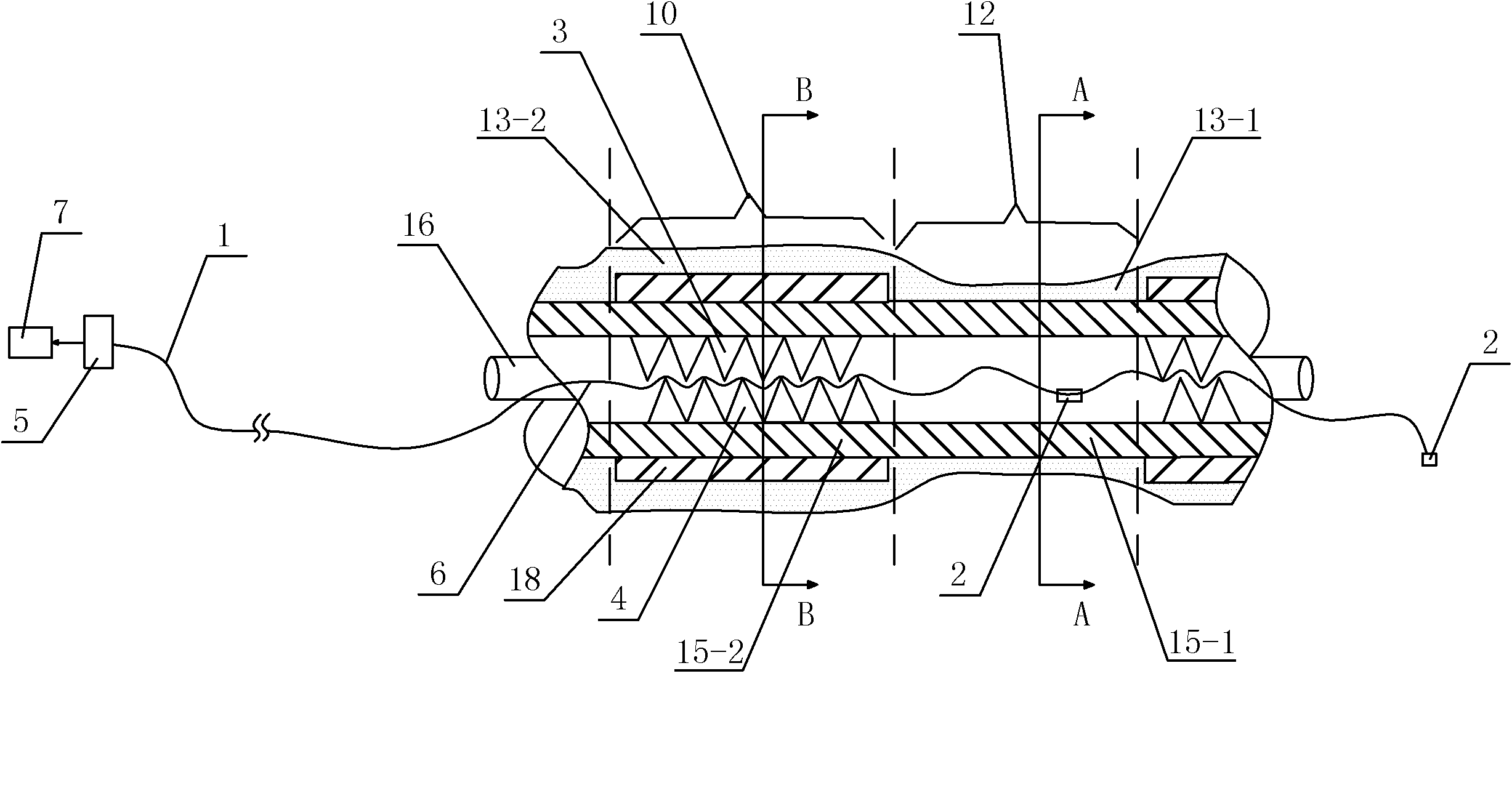

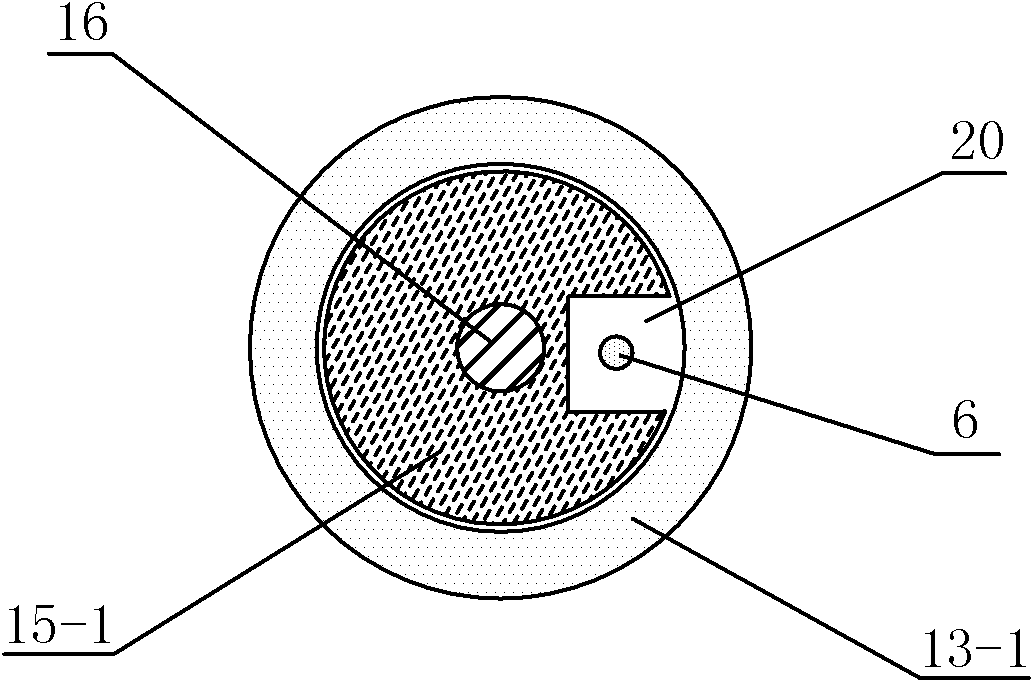

[0039] Such as figure 1 , 2 , 3 and 4 show a power cable with a built-in detection optical fiber, the conductor shielding layer 9, the insulating layer 11, the insulating shielding layer 14, the metal shielding layer 17 and the outer The outer sheath 19 is composed of at least one optical cable 21 inside the outer sheath 19. The optical cable 21 is composed of flexible segments 12 and rigid segments 10 arranged at even intervals. The flexible segment 12 and the rigid segment 10 The flexible segment 12 and the rigid segment 10 are connected with each other, and at least one signal optical fiber 6 is passed through the inside of the flexible segment 12 and the rigid segment 10. 1 is composed of a cylinder one 15-1 inside, the rigid segment 10 includes an outer sheath two 13-2 and a cylinder two 15-2 sleeved inside the outer sheath two 13-2, the cylinder one 15 -1 and cylinder two 15-2 are provided with a groove 20 inside, the signal optical fiber 6 is passed through the groove...

Embodiment 2

[0043] Such as Figure 5 As shown, in this embodiment, the difference from Embodiment 1 is that a through hole 22 is arranged in the center of the conductor 8 , and the optical cable 21 is located in the through hole 22 . In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com