Metal-oxide-metal capacitor structure

A technology of metal capacitors and oxides, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as limiting the application range of MOM capacitors, achieve the effects of reducing parasitic inductance and resistance, expanding application range, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

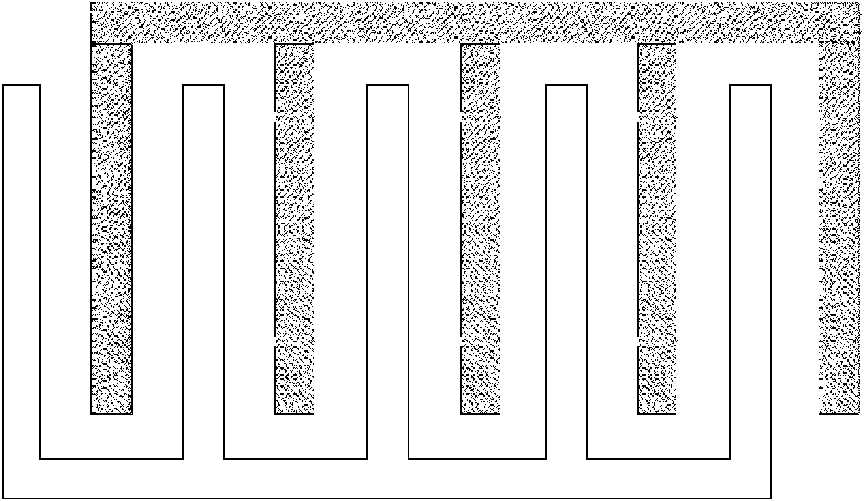

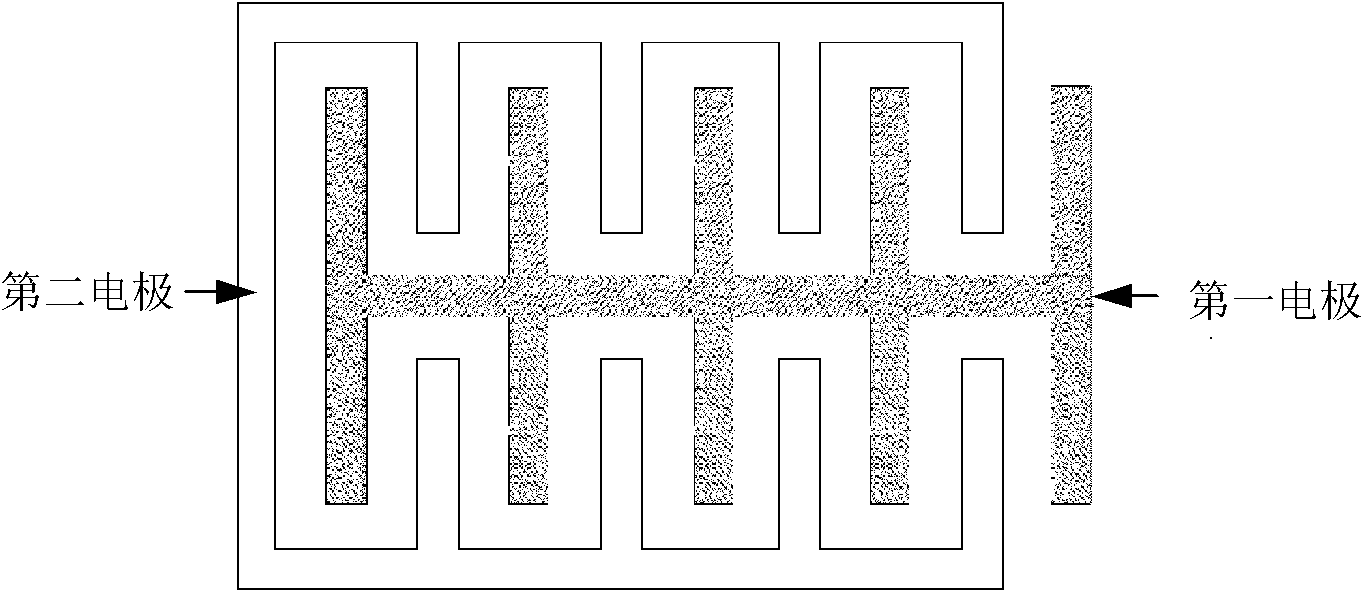

[0033] The fishbone MOM capacitance structure in the present embodiment, as figure 2 As shown, the capacitance structure is as follows:

[0034] On the same layer of metal (the material of the same layer of metal can be aluminum, copper, etc.), the first electrode (anode or cathode) of the fishbone MOM capacitor is made of the first group of metals that are parallel to each other, have equal lengths, and are aligned at the ends. (the material of the metal strip can be aluminum, copper, etc.), and the first group of parallel and equal metal strips is a metal strip perpendicular to it (the first group of metal strips) [the material of the metal strip can be Aluminum, copper, etc.] connection, the connection point is located at the midpoint of the parallel metal strips; the parallel metal strips can form an axisymmetric figure, and the symmetrical axis is the line connecting the midpoints of each metal strip;

[0035] On the same layer of metal, the second electrode (cathode or...

Embodiment 2

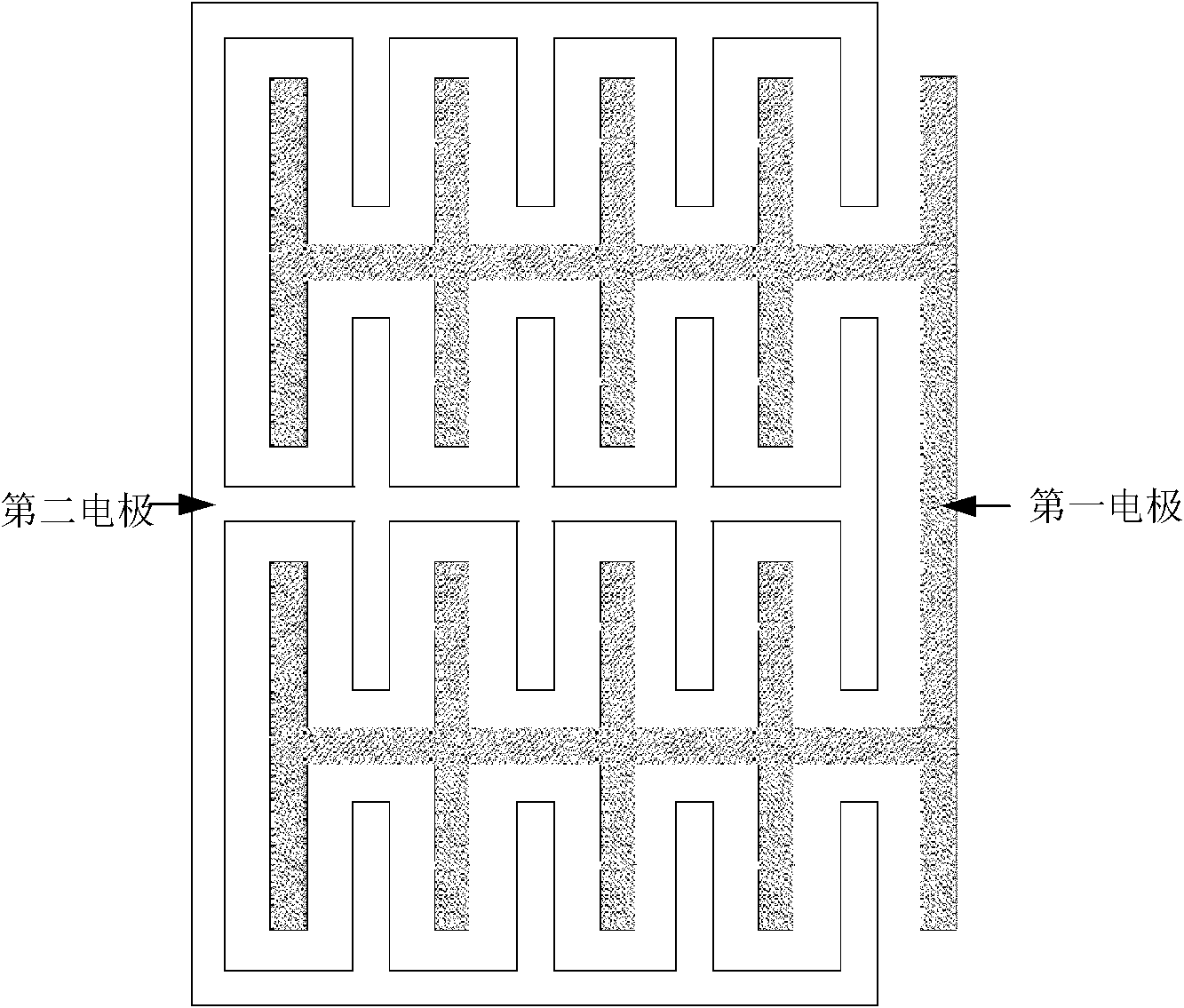

[0042] The stacked MOM capacitor structure (such as Figure 9 shown), similar to Example 1, but wherein, the structure and the repeating unit of the same layer of metal are changed to:

[0043] On the same layer of metal, the first electrode of the capacitor is composed of a stack of metal strips;

[0044] On the same layer of metal, the second electrode of the capacitor is composed of a metal strip that forms an interdigitated structure with the first electrode of the capacitor;

[0045] On the same layer of metal, the second electrode of the capacitor surrounds the first electrode in a ring, and the ring can be a closed ring or an open ring;

[0046] Using the structure described above as the smallest repeating unit to form a capacitive structure, such as Figure 10 , Figure 11 shown.

[0047] The MOM capacitor structure in this embodiment can be formed by a multi-layer metal (eg, 6-layer) structure, and the material, pattern, capacitor polarity and connection relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com