Method for separation and regeneration of anion and cation resin in exhausted mixed bed

A technology of anion-yang resin and mixed bed, which is applied in the field of separation and regeneration of anion-yang resin, can solve the problems of poor separation effect, large water and alkali consumption, and achieve the effects of preventing resin clustering, saving time, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

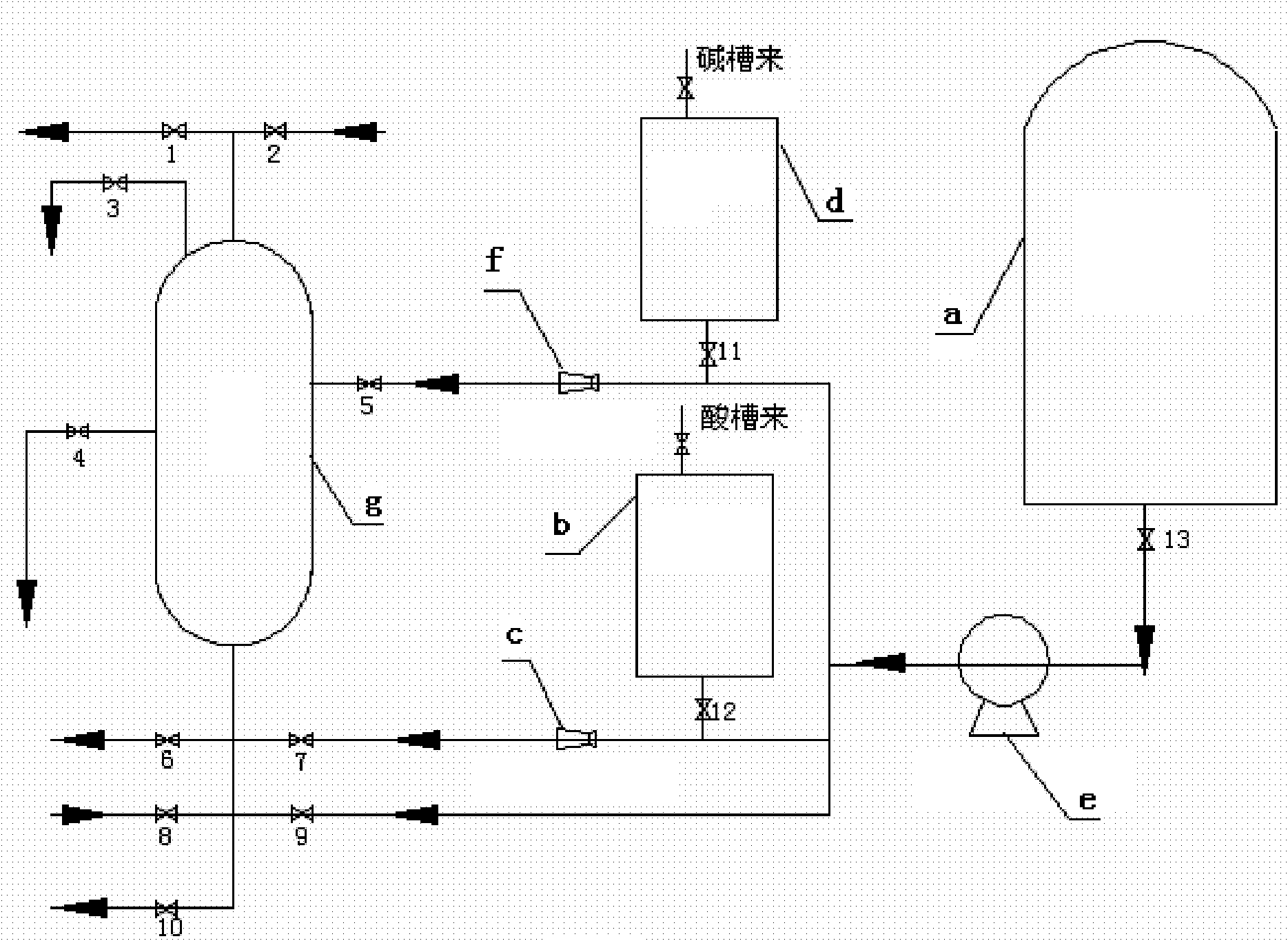

[0020] The method for regeneration and separation of anion and yang resins in an invalid mixed bed, the steps are as follows:

[0021] a) Drainage: open the exhaust valve 3 and the bottom drain valve 6, drain the water in the mixed bed, and close all the above valves. b) Separation: open the desalted water outlet valve 13, the mixed bed acid inlet valve 7, the backwash drain valve 1, and then start the desalted water pump e in sequence (the desalted water pump e is connected to the desalted water tank a through the desalted water outlet valve 13), Acid metering box outlet valve 12, adjust acid injector c (acid injector c is connected to acid metering box b through acid metering box outlet valve 12) outlet hydrochloric acid solution concentration range is 4%, control flow rate is 10t / h, continue to add Hydrochloric acid solution for 12 minutes (that is, the rinsing time), in order to rinse and separate the anion and cation resins in the mixed bed g. c) Drainage: open the exhau...

Embodiment 2

[0024] Under the situation that separation step is identical with embodiment 1, concrete operation parameter is:

[0025] b) Separation: hydrochloric acid solution with a concentration range of 2%, the control flow rate is 13t / h, and the rinsing time is 20 minutes. e) Regeneration: NaOH alkali solution with a concentration range of 2%, hydrochloric acid solution with a concentration range of 2%, and the time is 50 minutes.

Embodiment 3

[0027] Under the situation that separation step is identical with embodiment 1, concrete operation parameter is:

[0028] b) Separation: hydrochloric acid solution with a concentration range of 5%, the control flow rate is 7t / h, and the rinsing time is 5 minutes. e) Regeneration: NaOH alkali solution with a concentration range of 4%, hydrochloric acid solution with a concentration range of 5%, and the time is 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com