Application of rhodococcuserythropolis in separation of hematite and separation method thereof

A technology of rhodococcus and hematite, which is applied to hematite. , In the field of Rhodococcus erythrococcus, it can solve the problems of small harvesting capacity and few research results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

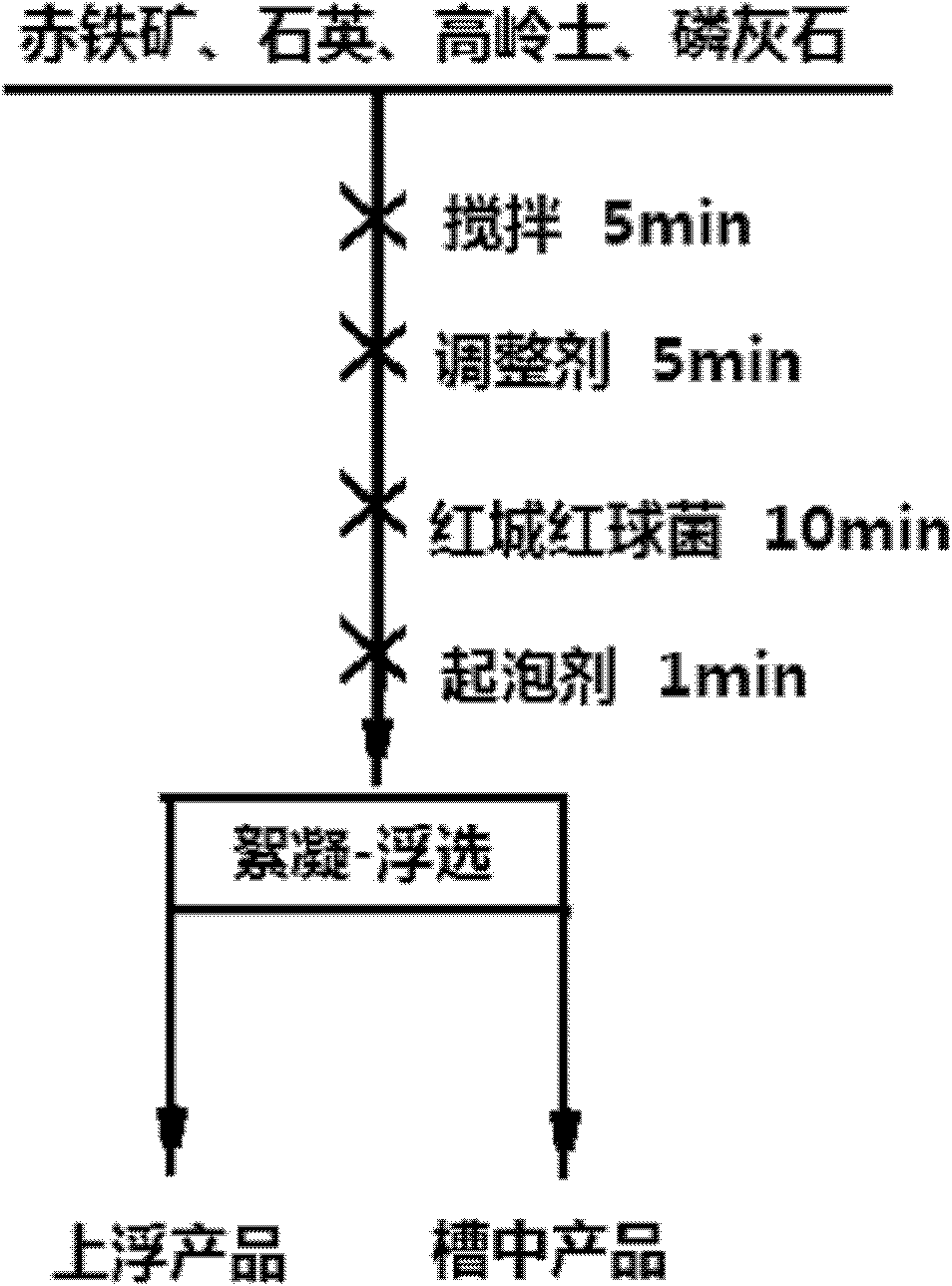

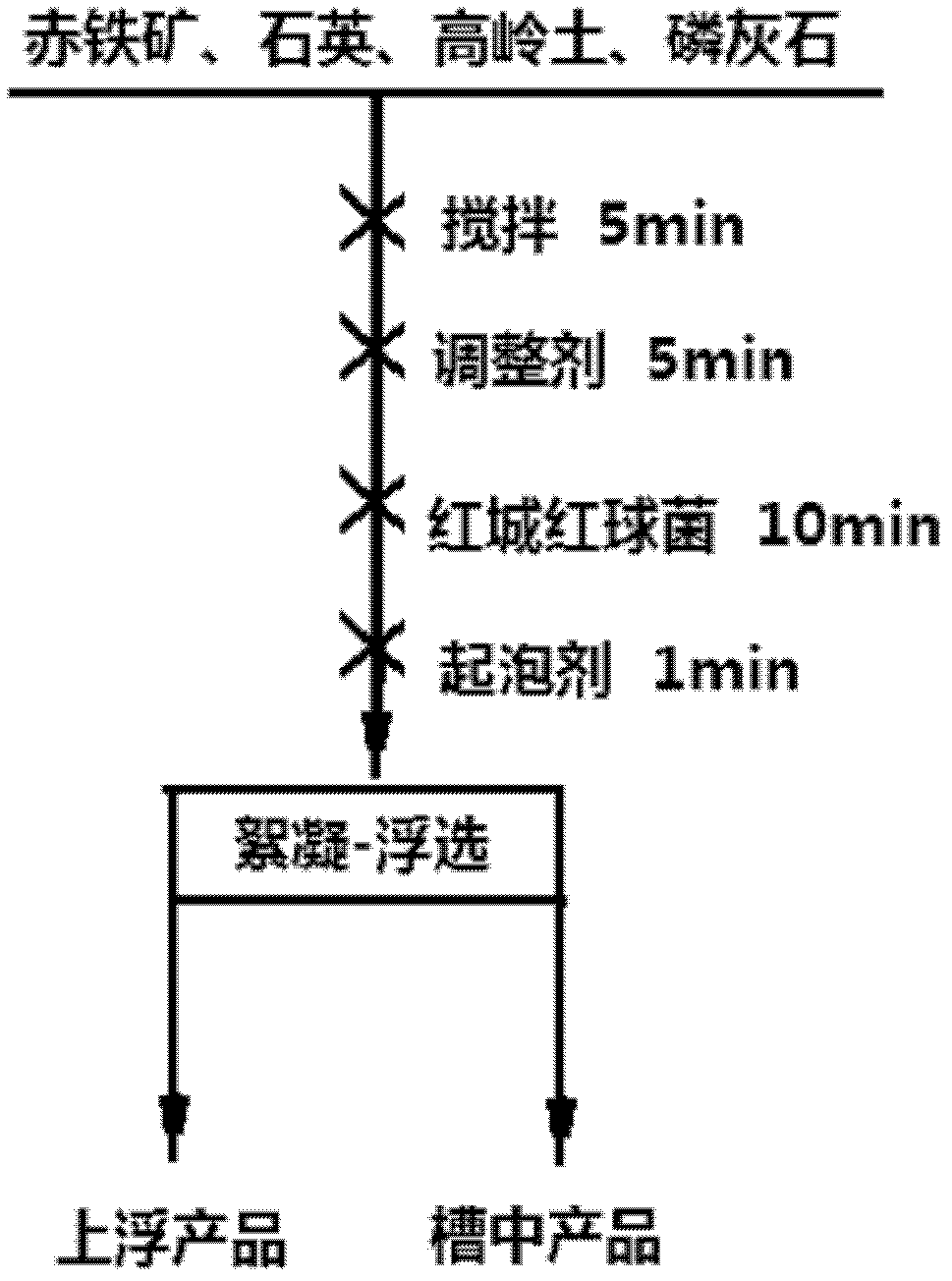

Method used

Image

Examples

Embodiment 1

[0025]Hematite with a purity of 97.6%, 99.9% quartz, 99% apatite and 99% kaolin, all of which are ground to -30μm in particle size, when the pH of the slurry is 6, the dosage of water glass is 150g / t, and the dosage of Rhodococcus erythrococcus is 65g Flotation was carried out under the conditions of 1 / t and 20 g / t of foaming agent, and the yields of the floating products obtained were 86.02%, 20.28%, 25.68% and 22.19%, respectively. The yield of hematite is significantly higher than that of quartz, apatite and kaolin, which are 65.74%, 60.39% and 63.83%, respectively. Microscopic observation shows that: Rhodococcus red city has obvious flocculation effect on hematite, but little flocculation effect on quartz, apatite and kaolin. It is precisely because the formation of hematite flocs creates a particle size condition that is conducive to hematite flotation, and a higher single mineral flotation yield is obtained.

Embodiment 2

[0027] The particle size is -30μm, the hematite (containing 68.28% iron) with a purity of 97.6% and the quartz with a purity of 99.9% are mixed in a weight ratio of 1:1 to form a mixed ore containing 31.23% iron. Flotation was carried out under the conditions of 70g / t of Rhodococcus erythrococcus and 20g / t of frother. The iron grade of the obtained iron concentrate was 51.63%, and the iron recovery rate was 71.14%. Microscopic observation shows that: the hematite in the iron concentrate exists in the form of flocs, and the quartz appears in the hematite flocs in the form of fine particles.

Embodiment 3

[0029] The particle size is -30μm, and the hematite (containing iron 68.28) with a purity of 97.6% and kaolin with a purity of 99% are mixed in a weight ratio of 1:1 to form a mixed ore containing 33.45% iron. The pH of the slurry is 5.5, and the amount of water glass is 150g Flotation was carried out under the conditions of 70g / t of Rhodococcus erythrococcus and 20g / t of frother. The iron grade of the obtained iron concentrate was 49.21%, and the iron recovery rate was 77.13%. Microscopic observation shows that the hematite in the iron concentrate exists in the form of flocs, and the kaolin is entrained in the hematite flocs in the form of fine particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com