Multifunctional separator for recycling of waste fluorescent lamps

A fluorescent tube recycling technology, which is applied in the recycling of lamp tubes/lamp materials, electronic waste recycling, repair/regeneration of defective lamp tubes/lamps, etc., can solve the problem of ineffective and rapid separation, glass fragments of lamp tubes, aluminum caps and Copper-plated filaments are doped with each other to achieve the effect of simple structure, high work efficiency and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

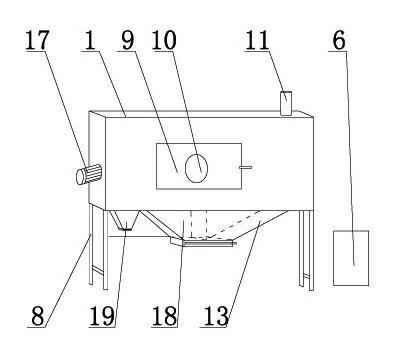

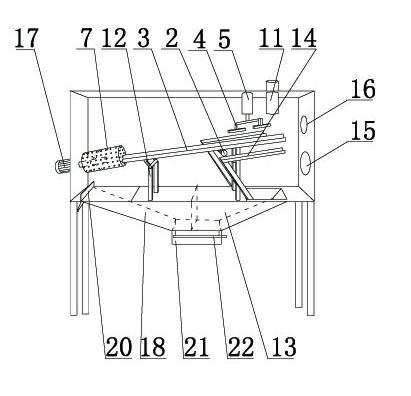

[0015] The multifunctional separator used for recycling waste fluorescent lamp tubes is composed of a separator housing 1 , a vibrating motor 2 , a vibrating tank 3 , an electromagnet 4 , a rotating cylinder 5 , a program control cabinet 6 and a filter screen 7 . The lower end of the separator housing 1 is provided with a bracket 8 , and the separator housing 1 at the front end is provided with a sealed door 9 , and an observation window 10 is provided on the sealed door 9 .

[0016] A feed cylinder 11 is arranged on the top of the separator housing 1 , and one end of the feed cylinder 11 extends into the separator housing 1 . A rotating cylinder 5 is arranged on the top of the housing on one side of the feed cylinder 11 in the separator housing 1 , and an electromagnet 4 is installed on the cylinder piston of the rotating cylinder 5 .

[0017] A vibrating tank 3 is movably installed below the feeding cylinder 11 and the electromagnet 4 through a mounting bracket 12, and a fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com