Method and device for controlling tiny droplet spraying by airflows

A micro-droplet and airflow control technology, which is applied in printing and other directions, can solve the problem of no airflow control micro-droplet micro-droplet spraying device, etc., and achieve the effect of simple structure and simple processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

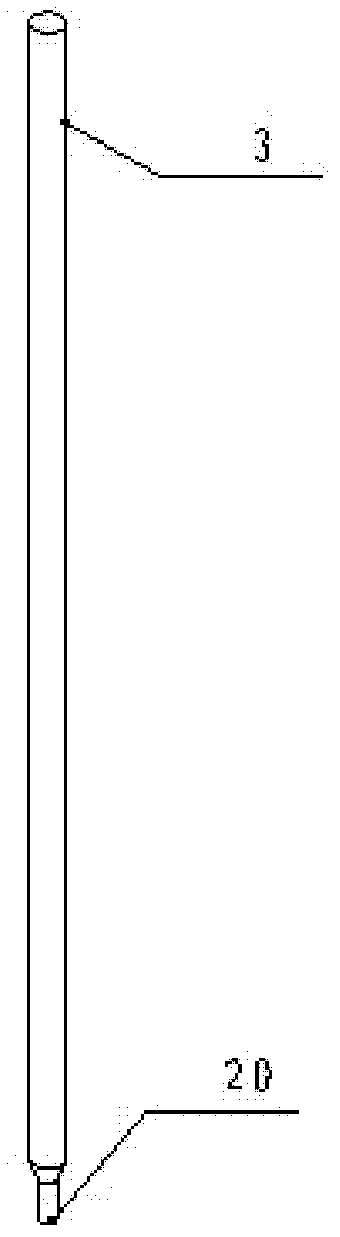

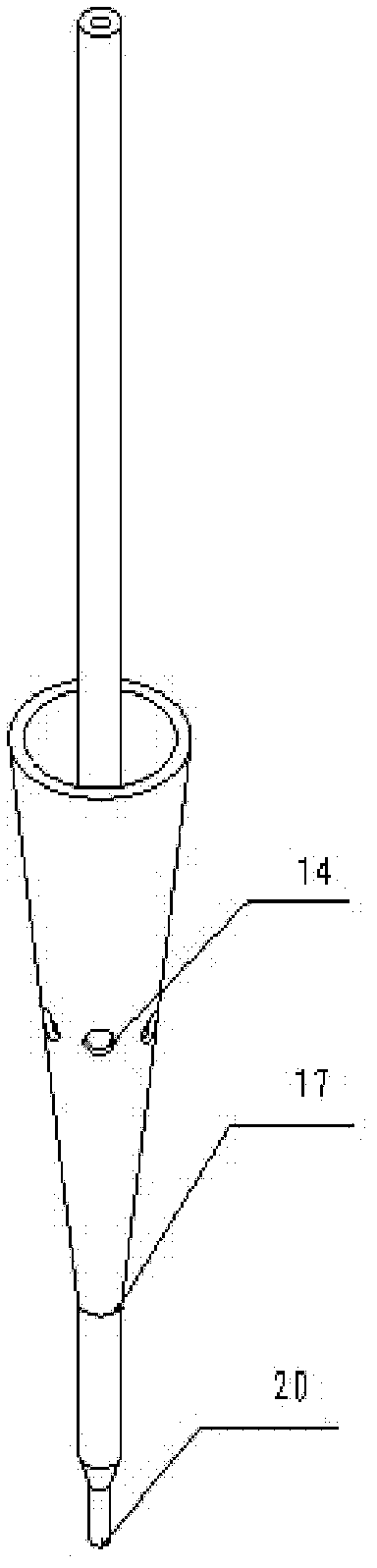

[0086] (1) Production of quartz capillary dripper

[0087] Such as figure 1 , 5 , take a 30cm long quartz capillary (inner diameter 25um×outer diameter 300um), take 1cm from one end and burn it on an alcohol lamp until the outer protective layer (polyimide) completely turns black, remove the blackened outer protective layer, Remove one end of the outer protective layer and insert it into a hydrofluoric acid solution for etching, measure the outer diameter of the capillary dropper 20 under a microscope, take it out when the capillary dropper 20 reaches 40um, etch for 10 hours, and finally rinse the capillary dropper 20 with a large amount of water .

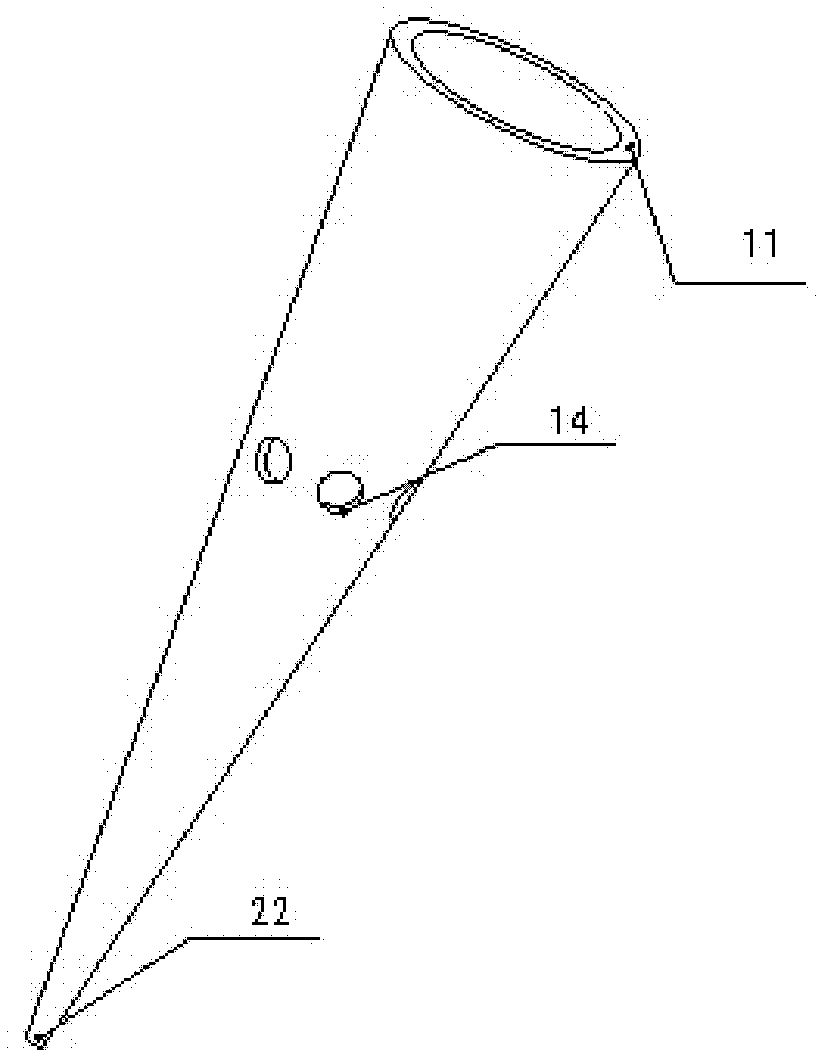

[0088] (2) Production of small tapered tubes

[0089] Such as figure 2 , take a small pipette tip 1 (6×50mm), place a 5mL disposable syringe needle on an alcohol lamp and burn it until it turns red. Get 6 through holes 14, each hole is the same size and the hole position spacing is equal.

[0090] (3) Production of large ta...

Embodiment 2

[0099] (1) Production of quartz capillary dripper

[0100] Take a section of 30cm long quartz capillary (inner diameter 25um×outer diameter 300um), take 1cm from one end and burn it on an alcohol lamp until the outer protective layer (polyimide) turns black completely, then remove the blackened outer protective layer as Capillary dropper, the outer diameter of the capillary dropper measured under a microscope is 280um.

[0101] (2) Production of small tapered tubes

[0102] Such as figure 2 , take a small pipette tip 1 (6×50mm), place a 5mL disposable syringe needle on an alcohol lamp and burn it until it turns red. Get 6 through holes 14, each hole is the same size and the hole position spacing is equal.

[0103] (3) Production of large tapered tubes

[0104] Such as Figure 4 , 5 , take a large pipette tip 2 (8 × 70mm), cut off 1 cm at the tip of the tip, and obtain 16 holes with a diameter of 3 mm at the tip.

[0105] (4) Casing production

[0106] Such as Figure...

Embodiment 3

[0112] The steps of realizing tiny droplet ejection with the device of the present invention are as follows:

[0113] (1), such as Figure 5 , 6 , Fix the assembled device in Example 1 on the iron stand, with the spout 19 and the capillary dripper 20 vertically downward.

[0114] (2), select a disposable syringe (1mL), a miniature syringe pump controller (Baoding Gelan TJ-1A), an exhaust pump (Haili ACO-9602); the disposable syringe is loaded with 200ppm rhodamine solution and placed in the syringe pump superior.

[0115] (3), such as Figure 5 , 6 , the capillary liquid inlet 1 is connected with the disposable syringe needle on the micro-injection pump controller; the third nozzle 7 of the three-way glass tube is closely connected with the gas generator (gas outlet of the exhaust pump).

[0116] (4), set the controller parameters of the exhaust pump and the micro-injection pump, and turn on the exhaust pump and the micro-injection pump controllers in sequence.

[0117] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com