PVA (Polyvinyl Acetate) vertical dip coating pattern printing film and preparation method and printing technology thereof

A technology for printing films and patterns, used in printing, printing devices, and ink transfer from manuscripts, etc., can solve the problems of low printing efficiency, high processing cost, low success rate, etc., and achieve the effect of improving printing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

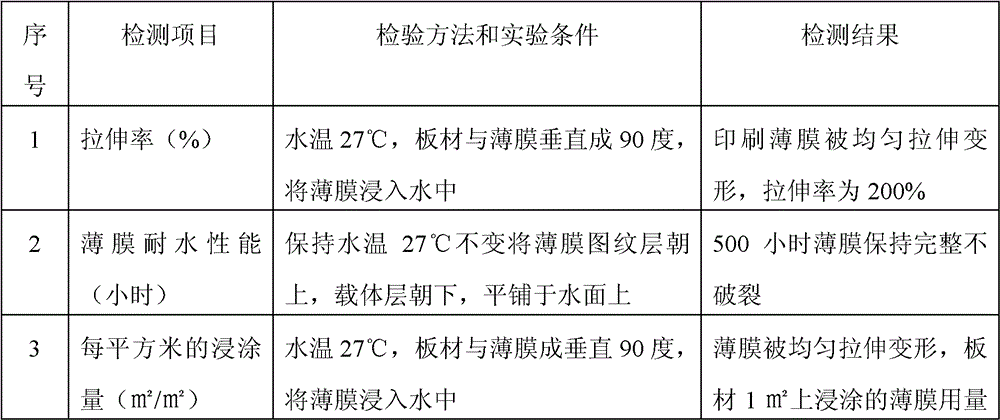

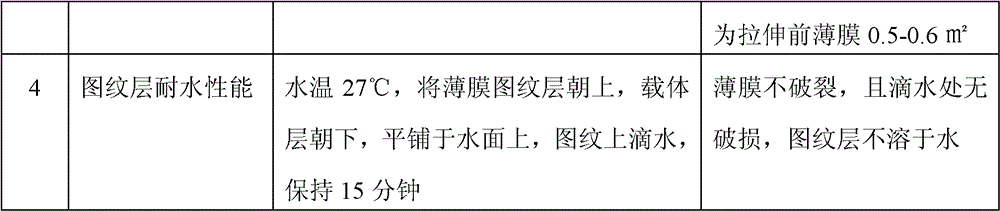

[0026] Below in conjunction with the specific preparation method of the printed film of the present invention and the printing process using the film of the present invention, the present invention is further set forth:

[0027] The printing film of the present invention comprises a polyvinyl alcohol film carrier layer and a pattern layer printed on the carrier layer, the pattern layer is provided with three layers, the first layer is close to the carrier layer, the second layer is close to the first layer, and the third layer Adhere to the second layer.

[0028] The raw materials required for the first layer are two-component polyurethane ink (PU-1750), 5% PA610, 20% cyclohexanone, 15% butyl acetate, 15% of isopropanol. The above raw materials were mixed, stirred, and stood still for 120 minutes to obtain the first layer of required ink.

[0029] The raw materials required for the second layer are 32% acrylic resin, 3% cellulose butyrate resin, 17% cellulose acetate butyrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| humidity | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com