Soft infusion bag manual filling equipment and method for filling soft infusion bags by using same

A technology for infusion soft bags and filling equipment, applied in the field of semi-automatic filling equipment for infusion soft bags, can solve the problems of low filling precision, low filling efficiency, cumbersome operation process, etc., so as to improve the measurement precision and the filling efficiency. , to avoid the effect of uneven flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

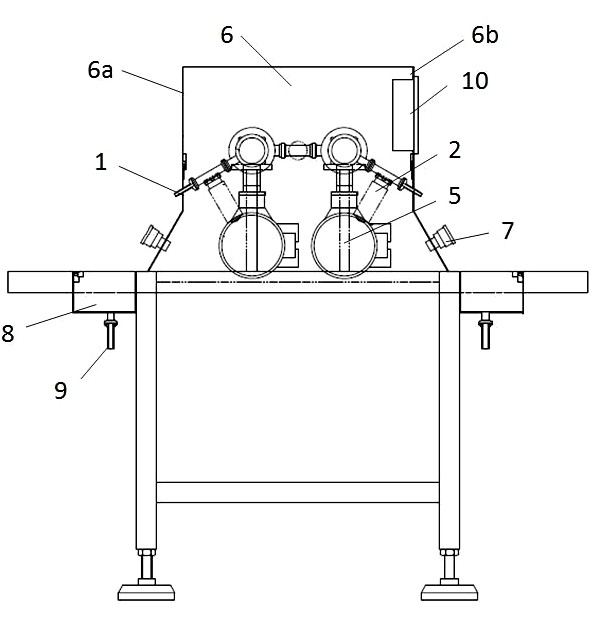

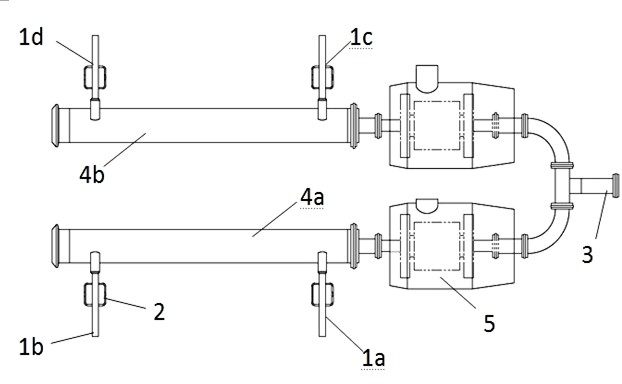

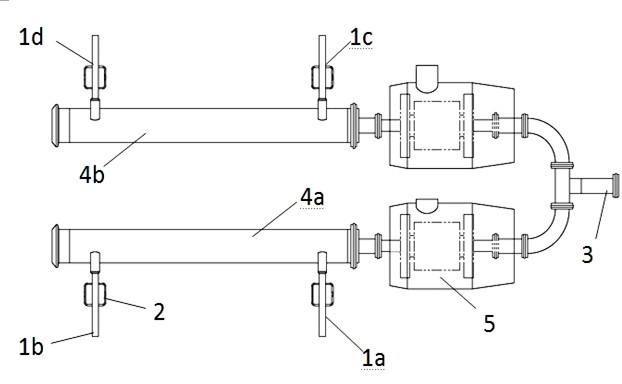

[0053] Such as figure 1 and figure 2 As shown, the manual filling equipment for infusion soft bags of the present invention includes a liquid supply device, the liquid supply device is provided with a liquid outlet nozzle 1, and the liquid outlet nozzle 1 is provided with a valve 2, and the liquid supply device includes a liquid inlet pipeline 3, and At least two liquid outlet branches 4 communicated with the liquid inlet pipeline 3, a flowmeter 5 is arranged between each liquid outlet branch 4 and the liquid inlet pipeline 3, and the signal input of the flowmeter 5 and the PLC controller 10 The signal output terminal of the PLC controller 10 is connected to the valve 2, and at least one liquid outlet nozzle 1 is connected to each liquid outlet branch 4.

[0054] Wherein, the liquid supply device can provide the whole device with medicinal liquid for filling. The liquid supply device includes a liquid inlet pipeline 3, and the liquid inlet pipeline 3 on the liquid supply de...

Embodiment 2

[0063] Such as figure 1 and figure 2 As shown, in the manual filling equipment for infusion soft bags in this embodiment, the liquid inlet line 3 is provided with a quick snap joint, and the quick snap joint can be snapped and sealed with the mouth of the water delivery system or the liquid medicine storage tank and other equipment. connection for quick disassembly.

[0064] Please refer to Embodiment 1 for other structures.

Embodiment 3

[0066] Such as figure 1 and figure 2 As shown, in the manual filling equipment for infusion soft bags in this embodiment, the quantity of the liquid inlet pipeline 3 is one, and one liquid inlet pipeline 3 is connected with two liquid outlet branches 4, and the liquid inlet pipeline 3 and the liquid outlet branch The path 4 forms a three-way structure, and the liquid medicine is input from the liquid inlet line 3 and flows into the two liquid outlet branches 4 .

[0067] Please refer to Embodiment 1 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com