Oxidizing tower in hydrogen peroxide production

An oxidation tower and hydrogen peroxide technology, applied in the field of oxidation towers, can solve the problems of increasing wall flow and axial backmixing, small grid block spacing, and excessively long residence time, so as to reduce wall flow and axial backmixing, The effect of preventing coking of polymerization and reasonable flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

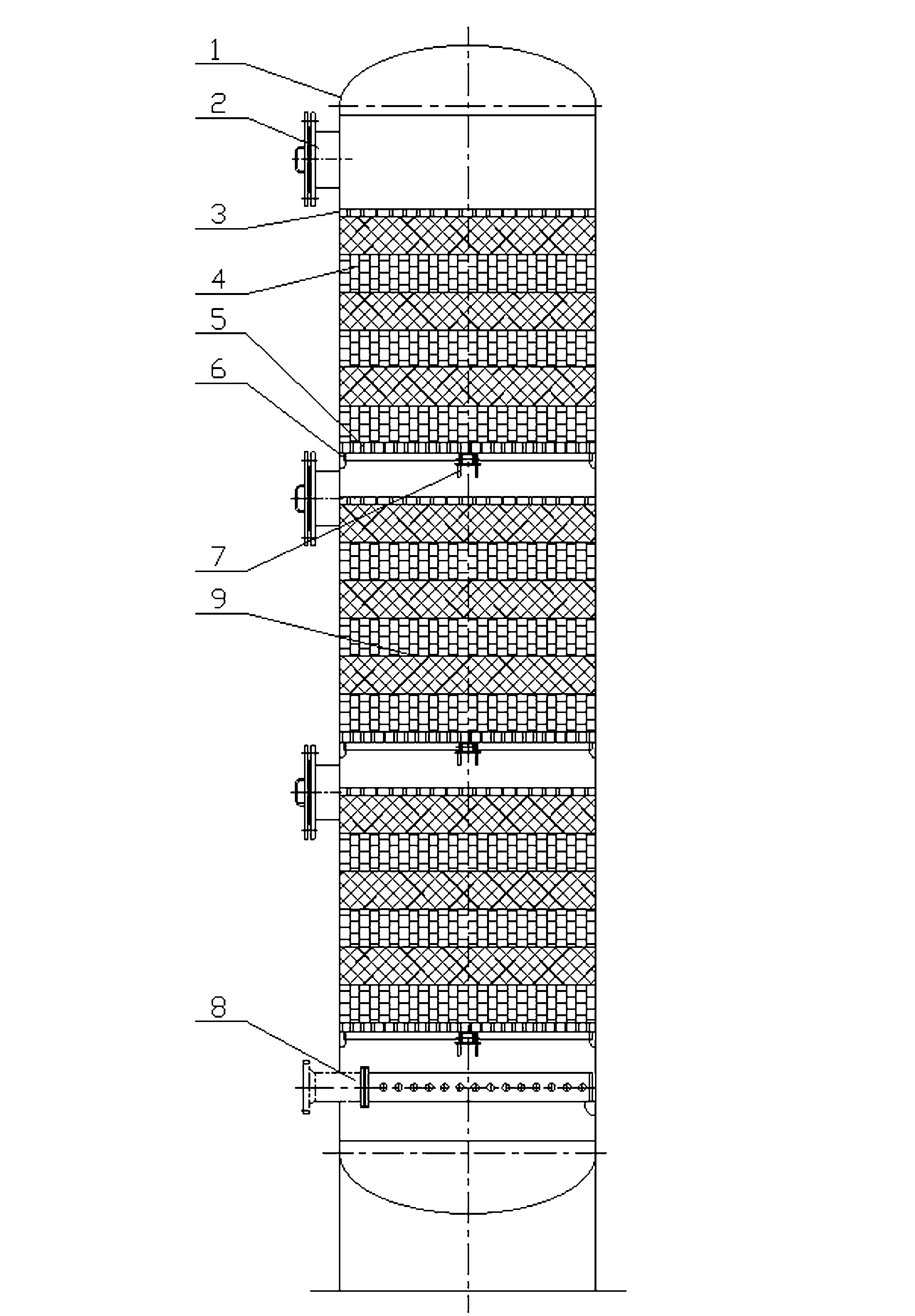

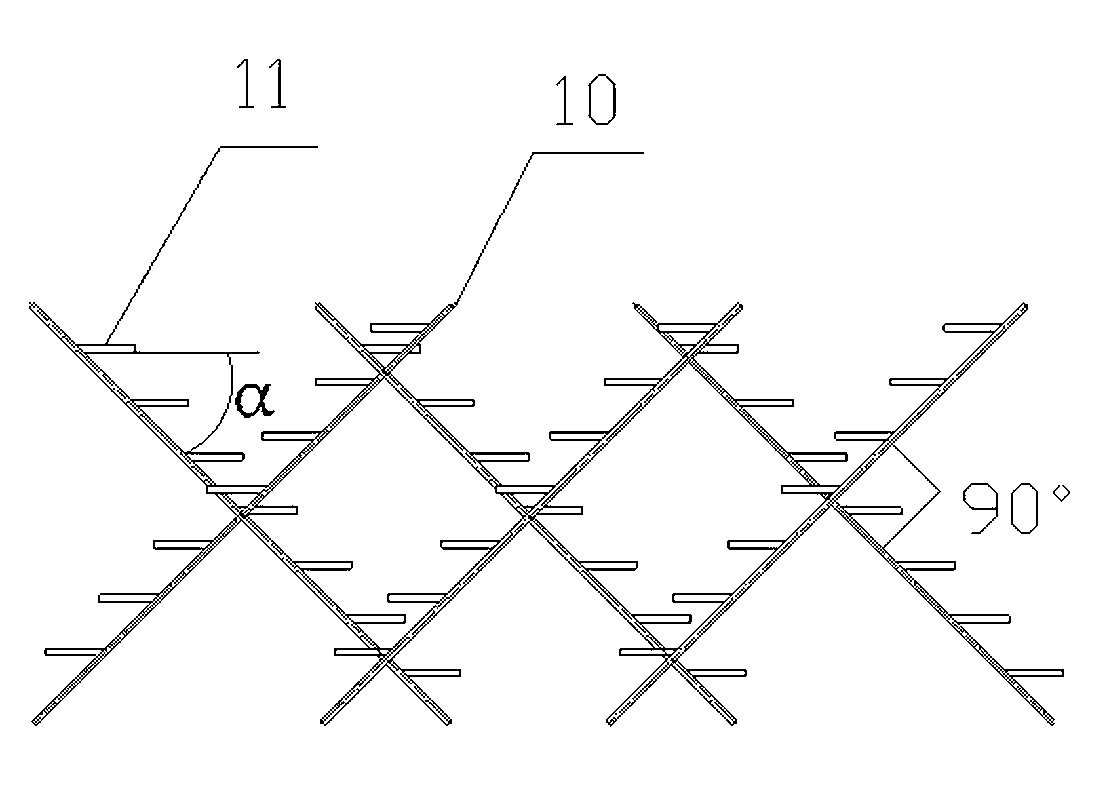

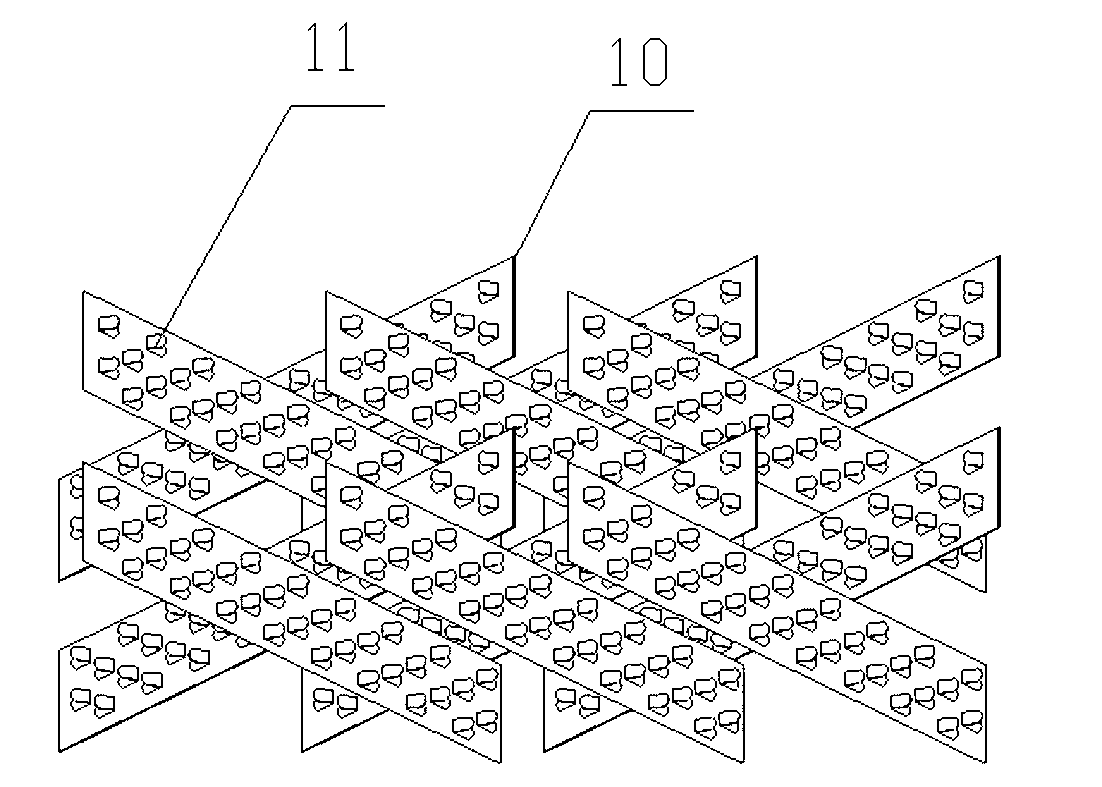

[0020] like Figure 1-6 As shown, an oxidation tower in the production of hydrogen peroxide of the present invention includes a tower body 1, and three packing parts 9 are arranged inside the tower body 1, and the packing parts 9 include a packing pressure ring 3 and a lower packing ring arranged on the upper side. The packing support block 6 on the side, the packing support block 6 is welded on the tower body 1, the multi-layer tongue-shaped packing 4 is arranged between the packing pressure ring 3 and the packing support block 6, and the adjacent two layers of tongue-shaped packing The filler 4 is installed crosswise at a 90° angle to increase the degree of disturbance of the two phases to make the mixing more uniform and improve the mass transfer efficiency. A filler support grid 5 is arranged between the tongue-shaped filler 4 and the filler support block 6, so The bottom of the packing support block 6 is provided with a packing support beam 7, and the tower body 1 on one ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap