Coke oven flue gas waste heat ammonia distillation reboiler

A flue gas waste heat and reboiler technology, applied in the direction of climate sustainability, ammonia preparation/separation, sustainable manufacturing/processing, etc., can solve the problems of flue gas heat waste, large energy consumption, and energy consumption. Achieve the effect of reducing usage, reducing sewage discharge, and reducing discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

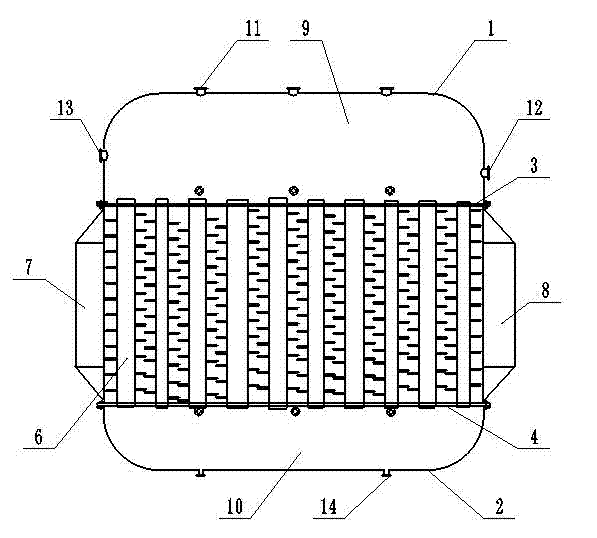

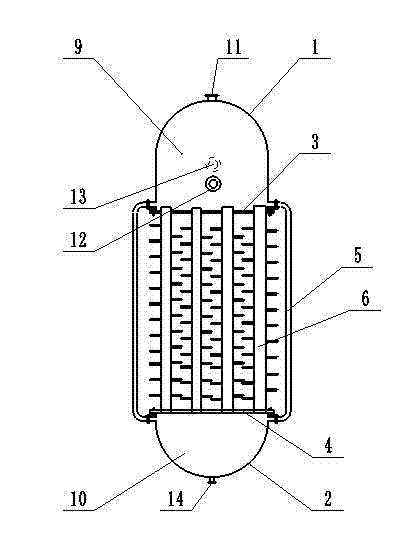

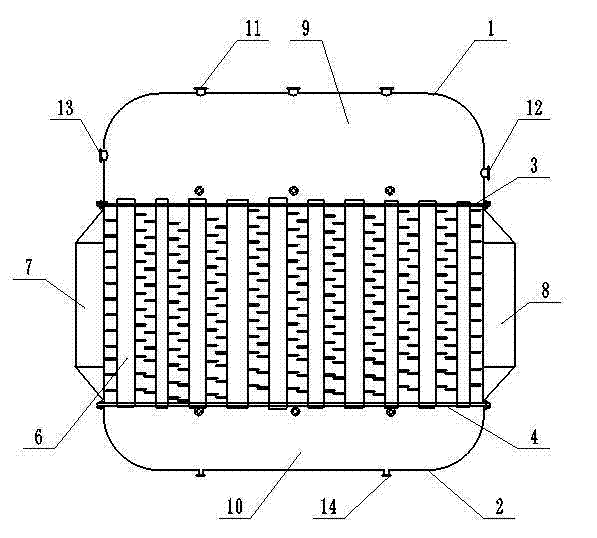

[0019] Such as figure 1 and figure 2 As shown, the coke oven flue gas waste heat ammonia distillation reboiler includes an upper shell 1, a lower shell 2, an upper tube plate 3, a lower tube plate 4, a circulation downcomer 5 and a plurality of evaporation tubes 6; The evaporating tubes 6 are installed vertically between the upper tube plate 3 and the lower tube plate 4. A flue gas inlet 7 is provided on one side of the plurality of evaporating tubes 6, and a flue gas inlet 7 is provided on the other side of the plurality of evaporating tubes 6. exit 8;

[0020] The upper tube plate 3 and the upper casing 1 form a vapor-liquid separation chamber 9, the top of the vapor-liquid separation chamber 9 is provided with a plurality of steam outlets 11, the side of the vapor-liquid separation chamber 9 is provided with a water inlet 12, and the vapor-liquid separation chamber The middle part of the other side of 9 is provided with an overflow port 13;

[0021] The lower tube plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com