Preparation method of tin dioxide nano material with controllable morphology

A technology of tin dioxide and nanomaterials, applied in the direction of tin oxide and nanotechnology, can solve the problems of uncontrollable shape, many defects, and long cycle, and achieve good shape controllability, high yield, and short experiment cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

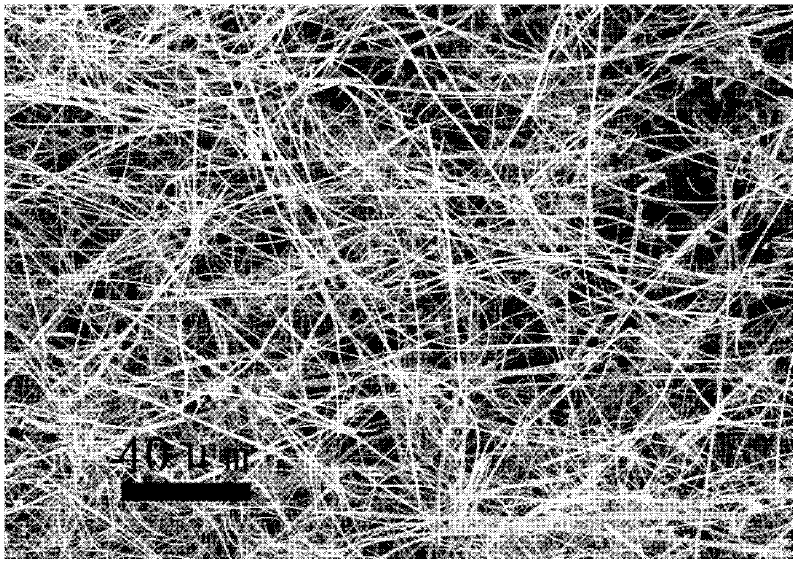

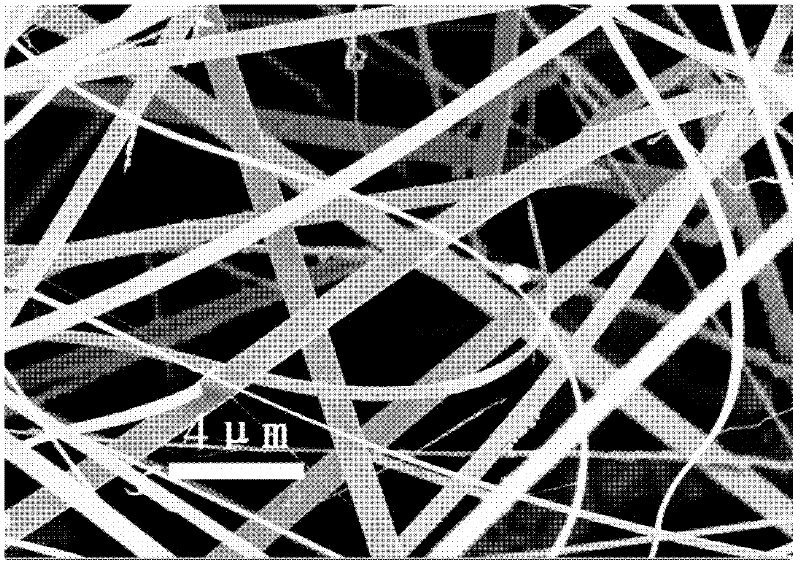

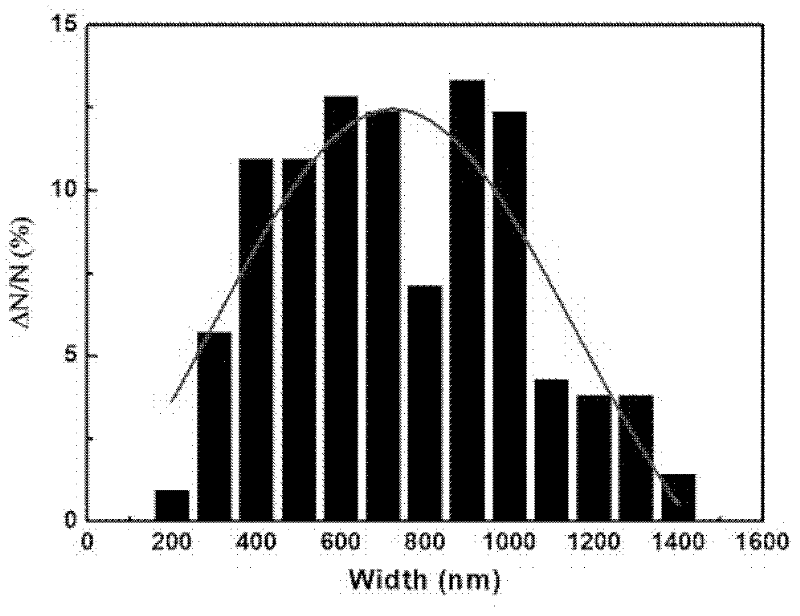

[0023] Elemental tin powder with a purity of 99.99% was put into a graphite crucible (aperture 20 mm, depth 20 mm) as an anode, which was placed in an arc chamber and fixed. Turn on the mechanical pump, evacuate the vacuum in the arc chamber to 16kPa, and then introduce argon gas at 24kPa. The distance between the cathode and the anode is controlled by the motor, the arc power supply is turned on, the discharge current is 60-70A, the discharge voltage is 20-25V, and the discharge time is 5 minutes. The product is tin dioxide nanobelts. Its product is characterized by Figure 1-3 shown.

Embodiment 2

[0025] Elemental tin powder with a purity of 99.99% was put into a graphite crucible (aperture 20 mm, depth 20 mm) as an anode, which was placed in an arc chamber and fixed. Turn on the mechanical pump to draw the vacuum in the arc chamber to 10kPa. The distance between the cathode and the anode is controlled by the motor, the arc power supply is turned on, the discharge current is 90-100A, the discharge voltage is 50-60V, and the discharge time is 4 minutes. The product is tin dioxide nanobelts.

Embodiment 3

[0027] Elemental tin powder with a purity of 99.99% was put into a graphite crucible (aperture 20 mm, depth 20 mm) as an anode, which was placed in an arc chamber and fixed. Turn on the mechanical pump, evacuate the vacuum in the arc chamber to 40kPa, and then inject 10kPa argon gas. The distance between the cathode and the anode is controlled by the motor, the arc power supply is turned on, the discharge current is 70-80A, the discharge voltage is 30-35V, and the discharge time is 5 minutes. The product is tin dioxide nanodisks. Its product is characterized by Figure 4-5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com