Dehydrating and drying method for producing isoprene rubber through solution polymerization process

A technology of isoprene rubber and drying method, which is applied in the field of dehydration and drying of isoprene rubber produced by solution polymerization method, can solve the problems of high labor intensity of workers, high equipment cost, and high requirements for workshops, and reduce equipment failure rate and equipment maintenance The effect of saving cost, saving equipment investment, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

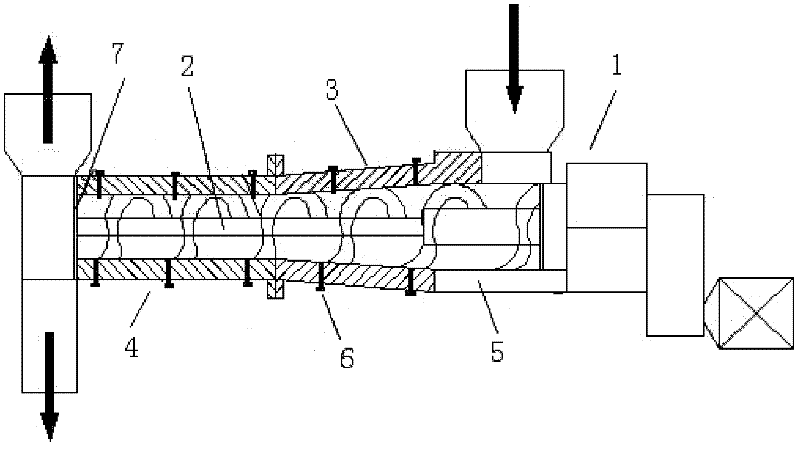

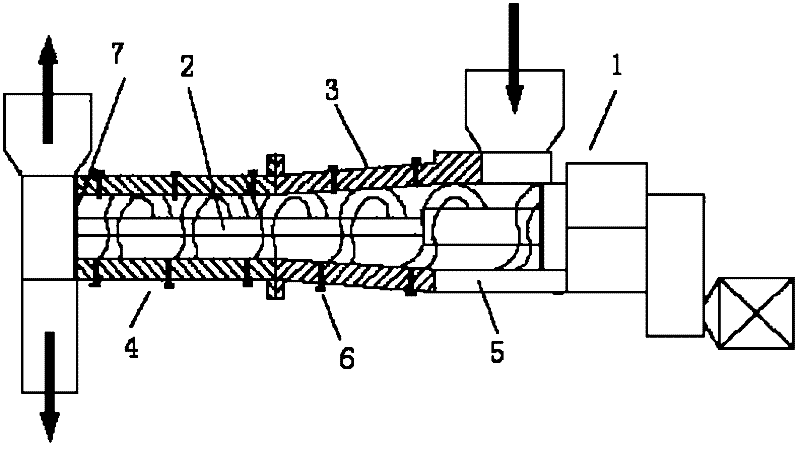

[0016] After removing most of the condensed water by the dehydration vibrating screen, the isoprene rubber particles contain 38% water, and enter the integrated machine 1 at 2 tons / hour, first pass through the extrusion dehydration section 3, and are pushed by the mechanical force of the rotating screw 2 Entering the expansion drying section 4, the extruded water is discharged through the drain 5 at the bottom. In the expansion drying section 4, the temperature of the material continues to rise under the combined action of the screw 2 and the shear screw 6. The material pressure in the extrusion dehydration expansion drying machine is controlled by the opening ratio of the template 7, and the material is extruded from the template 7. At the moment, the volatile substances in it are vaporized and drawn out due to the sudden drop in pressure, and the material enters the next process. During the dehydration and drying process, the screw speed of the integrated machine is controll...

Embodiment 2

[0018] After removing most of the condensed water by the dehydration vibrating screen, the isoprene rubber particles contain 35% water and enter the integrated machine 1 at a rate of 3 tons per hour. First, they pass through the extrusion dehydration section 3 and are pushed by the mechanical force of the rotating screw 2. Entering the expansion drying section 4, the extruded water is discharged through the drain 5 at the bottom. In the expansion drying section 4, the temperature of the material continues to rise under the combined action of the screw 2 and the shear screw 6. The material pressure in the extrusion dehydration expansion drying machine is controlled by the opening ratio of the template 7, and the material is extruded from the template 7. At the moment, the volatile substances in it are vaporized and drawn out due to the sudden drop in pressure, and the material enters the next process. During the dehydration and drying process, the screw speed of the extrusion d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com