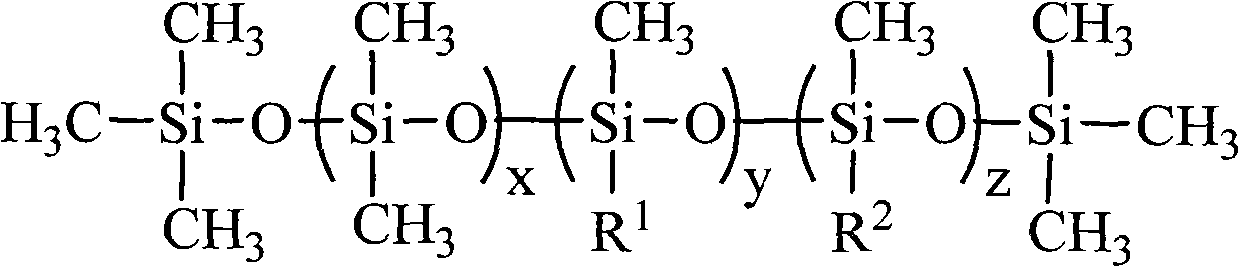

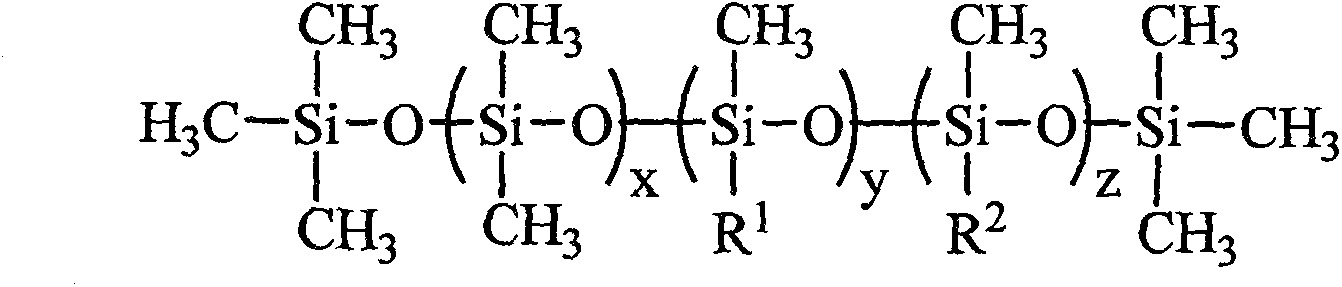

Preparation method of polysiloxane containing alkyl and glycosyl

A technology of polysiloxane and glycoside group, which is applied in the field of preparation of polysiloxane containing alkyl group and glycoside group, to achieve the effect of good emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

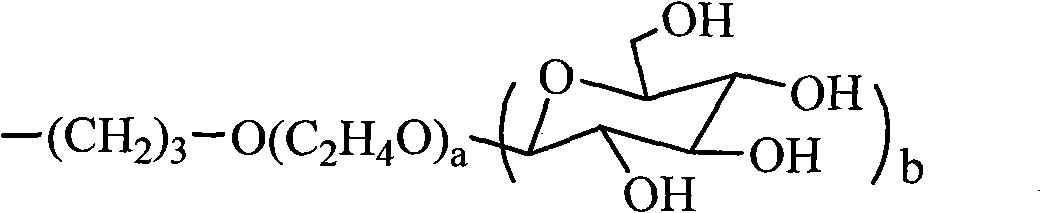

Method used

Image

Examples

Embodiment 1

[0020] Add 2.32kg of allyl alcohol, 1.26kg of glucose, and 48.16g of p-toluenesulfonic acid into the reaction kettle, heat to dissolve, and control the temperature at 100°C. After reacting under reduced pressure for 6 hours, add sodium hydroxide to neutralize the catalyst to make it Inactivate. Evaporate unreacted allyl alcohol under reduced pressure, add 0.34kg terminal olefin and 5.18kg hydrogen-containing silicone oil, heat to 120°C, and react for 8 hours to obtain a polysiloxane product containing alkyl and glycoside groups, and measure its surface tension It is 22.7mN / m.

Embodiment 2

[0022] Add 4.08kg of ethylene glycol monoallyl ether, 1.08kg of glucose, and 61.92g of p-toluenesulfonic acid into the reaction kettle, heat to dissolve, and control the temperature at 110°C. After reacting under reduced pressure for 7 hours, add sodium hydroxide and catalysts to deactivate them. Evaporate unreacted ethylene glycol monoallyl ether under reduced pressure, add 0.56kg terminal olefin and 8.14kg hydrogen-containing silicone oil, heat to 120°C, and react for 6 hours to obtain polysiloxane products containing alkyl and glycoside groups , The measured surface tension is 23.5mN / m.

Embodiment 3

[0024] Add 5.84kg of diethylene glycol monoallyl ether, 0.90kg of glucose, and 34.40g of p-toluenesulfonic acid into the reaction kettle, heat to dissolve, and control the temperature at 120°C. After reacting under reduced pressure for 8 hours, add sodium hydroxide Neutralizes the catalyst and deactivates it. Evaporate unreacted diethylene glycol monoallyl ether under reduced pressure, add 0.84kg terminal olefin and 2.22kg hydrogen-containing silicone oil, heat to 120°C, and react for 6 hours to obtain polysiloxane containing alkyl and glycoside groups Product, its surface tension measured is 21.2mN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com