Washing machine

A washing machine and machine body technology, applied in the field of washing machines, can solve the problems of environment-friendly development, water pollution, and clothing adhesion, etc., and achieve the effects of reducing the use of disinfectant or washing liquid, improving softness, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

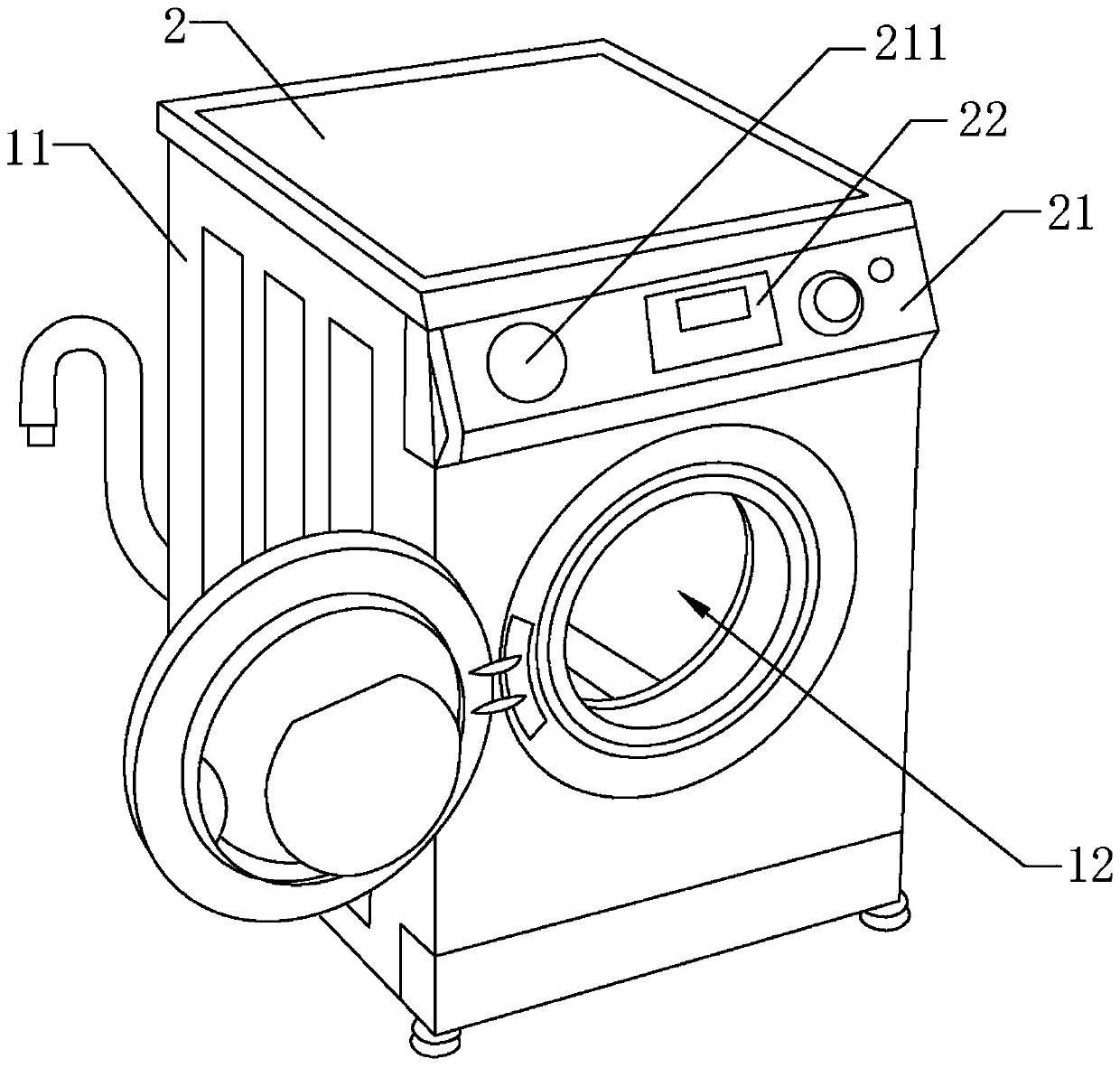

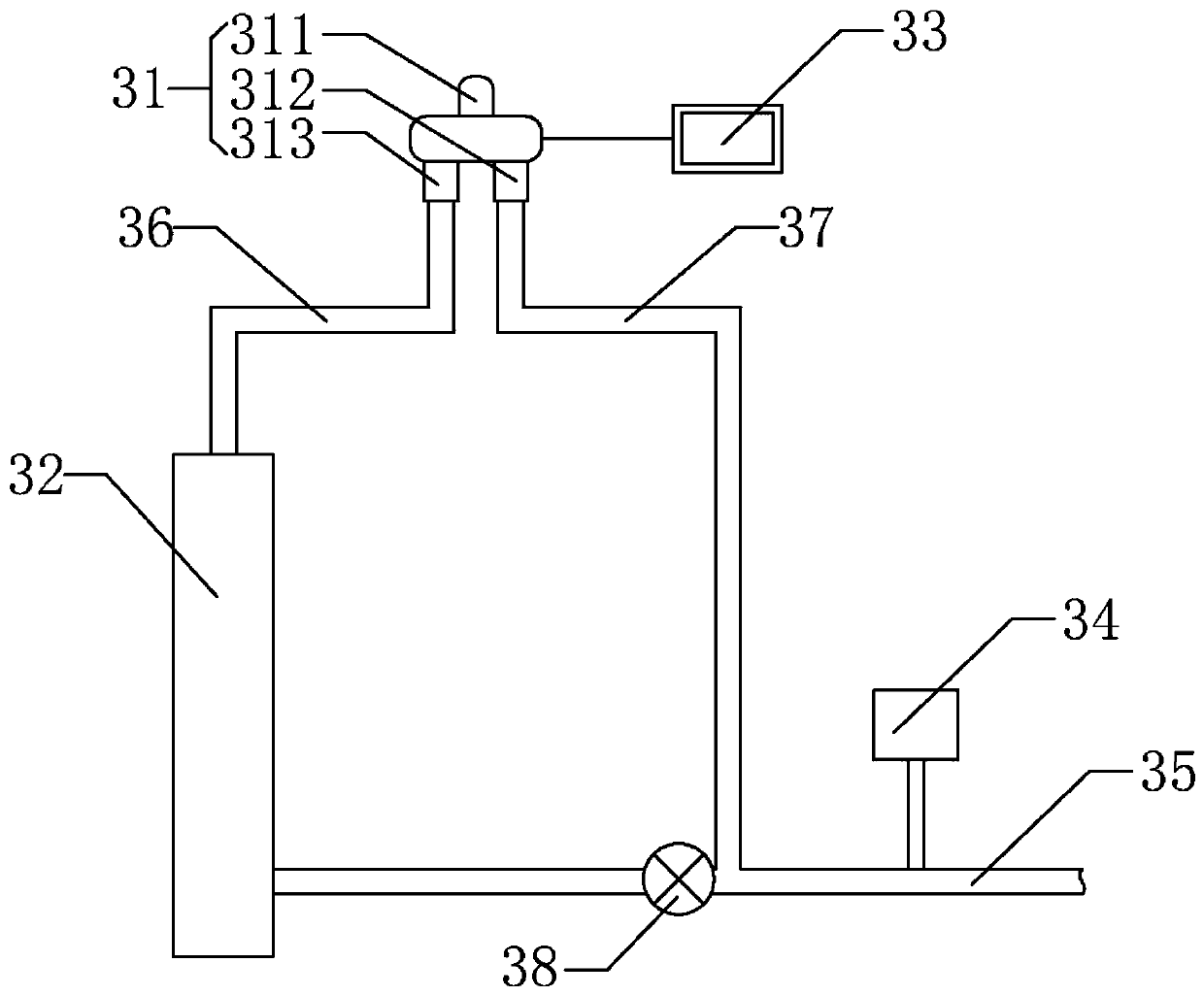

[0038] See Figure 1-2 , a washing machine, comprising a body 1 and a workbench 2 arranged on the top of the body 1, the body 1 includes a first shell 11, a washing tub 12 arranged in the first shell 11, and a washing machine for driving the washing machine. The motor for rotating the barrel 12, the workbench 2 includes a second casing 21, a control panel 22 arranged outside the second casing 21 and a water treatment device arranged inside the second casing 21, the control panel 22 There is a controller inside, and the water treatment device includes a double-head water inlet valve 31, a washing core 32, an electric valve 33, an ozone generator 34 and an outlet pipeline 35, and the ozone generator 34, the electric valve 33 and the motor are all connected with each other. The controller is electrically connected; the electric valve 33 is connected to the double-head water inlet valve 31;

[0039] The double-head water inlet valve 31 includes a water inlet section 311, a first ...

Embodiment 2

[0044] The difference between this embodiment and above-mentioned embodiment 1 is:

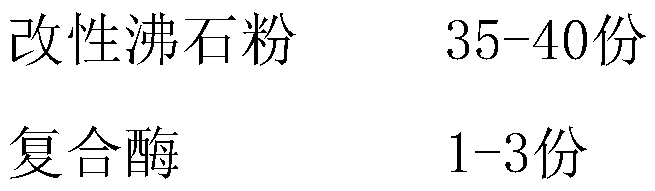

[0045] The core material includes the following raw materials in parts by weight:

[0046]

[0047] The compound enzyme is a mixture of alkaline protease and alpha-amylase in a weight ratio of 3-4:1.

[0048] The surfactant is sodium α-olefin sulfonate.

[0049] Described modified zeolite powder is made by following steps:

[0050] Step S1: Add zeolite powder to NaOH solution with a concentration of 2mol / L and soak for 4 hours, then add to 90°C, stir for 60 minutes, then perform suction filtration, repeatedly wash with deionized water, and dry to obtain zeolite powder modified intermediates;

[0051] Step S2: Take N-hexadecylpropylenediamine bisammonium chloride, disperse it in deionized water, then add the zeolite powder modified intermediate prepared in step S1, raise the temperature to 50°C, stir for 90min, and then carry out Suction filtration and drying to obtain modified zeolite p...

Embodiment 3

[0061] The difference between this embodiment and above-mentioned embodiment 1 is:

[0062] The core material includes the following raw materials in parts by weight:

[0063]

[0064]

[0065] The compound enzyme is a mixture of alkaline protease and alpha-amylase in a weight ratio of 3.2:1.

[0066] The surfactant is lauryl dimethyl betaine.

[0067] Described modified zeolite powder is made by following steps:

[0068] Step S1: Add zeolite powder to NaOH solution with a concentration of 3mol / L and soak for 3.5h, then add it to 95°C, stir for 50min, then perform suction filtration, wash repeatedly with deionized water, and dry to obtain zeolite powder modified intermediate;

[0069] Step S2: Take N-hexadecylpropylenediamine bisammonium chloride, disperse it in deionized water, then add the zeolite powder modified intermediate prepared in step S1, raise the temperature to 55°C, stir for 80min, and then carry out Suction filtration and drying to obtain modified zeoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com