Wear-resisting terrace material and installation and construction method thereof

A floor material and mixed slurry technology, applied in epoxy resin coating, coating, construction, etc., can solve the problems of unstable curing performance, long curing cycle, poor corrosion resistance, etc., and achieve short curing cycle and maintenance Short period, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

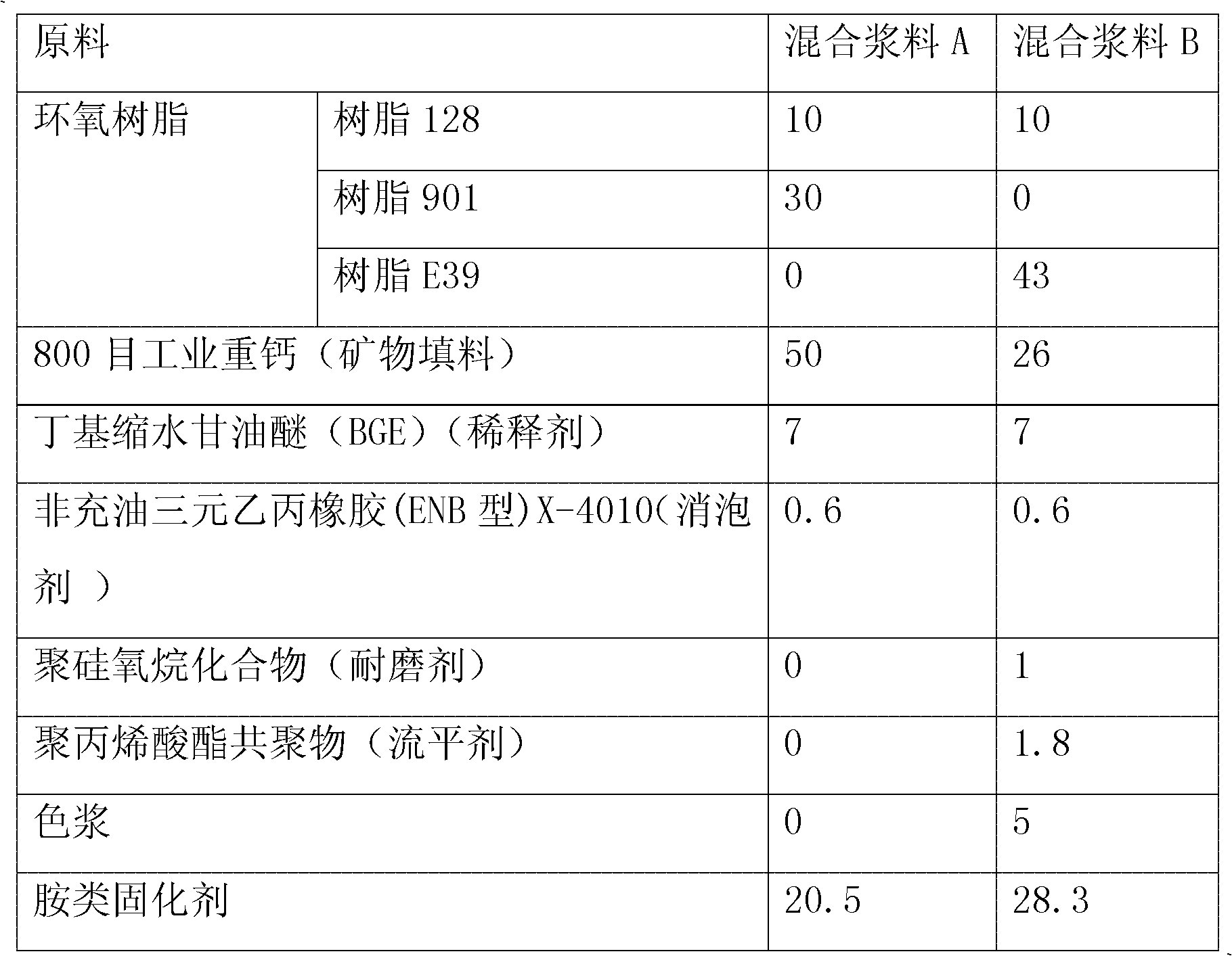

[0020] The formula of table 1 embodiment 1 (unit: weight part)

[0021]

[0022] First, mix all raw materials according to the formula in Table 1 to prepare one part of mixed slurry A and one part of mixed slurry B, and use a horizontal coating machine to uniformly coat mixed slurry A with a thickness of 0.25mm on the wet-process PU coating cloth (thickness 0.6mm, modulus 340) and warp-knitted woven glass fiber cloth (when glass fiber sizing, silane type size sizing is used for weft yarn, silane type size size is used for warp yarn, and the weaving density is 35 warp yarns / 10cm, 45 weft yarns / 10cm) compounded, sent to 80-115°C oven with gradient temperature for baking, the temperature gradient is 5°C, baked for 1.5 minutes at each temperature gradient, and then the mixed slurry B was mixed with 0.3mm The thickness is evenly coated on the warp-woven glass fiber cloth, and then rolled into an oven with a gradient temperature of 65-110°C for baking. The temperature gradient is...

Embodiment 2

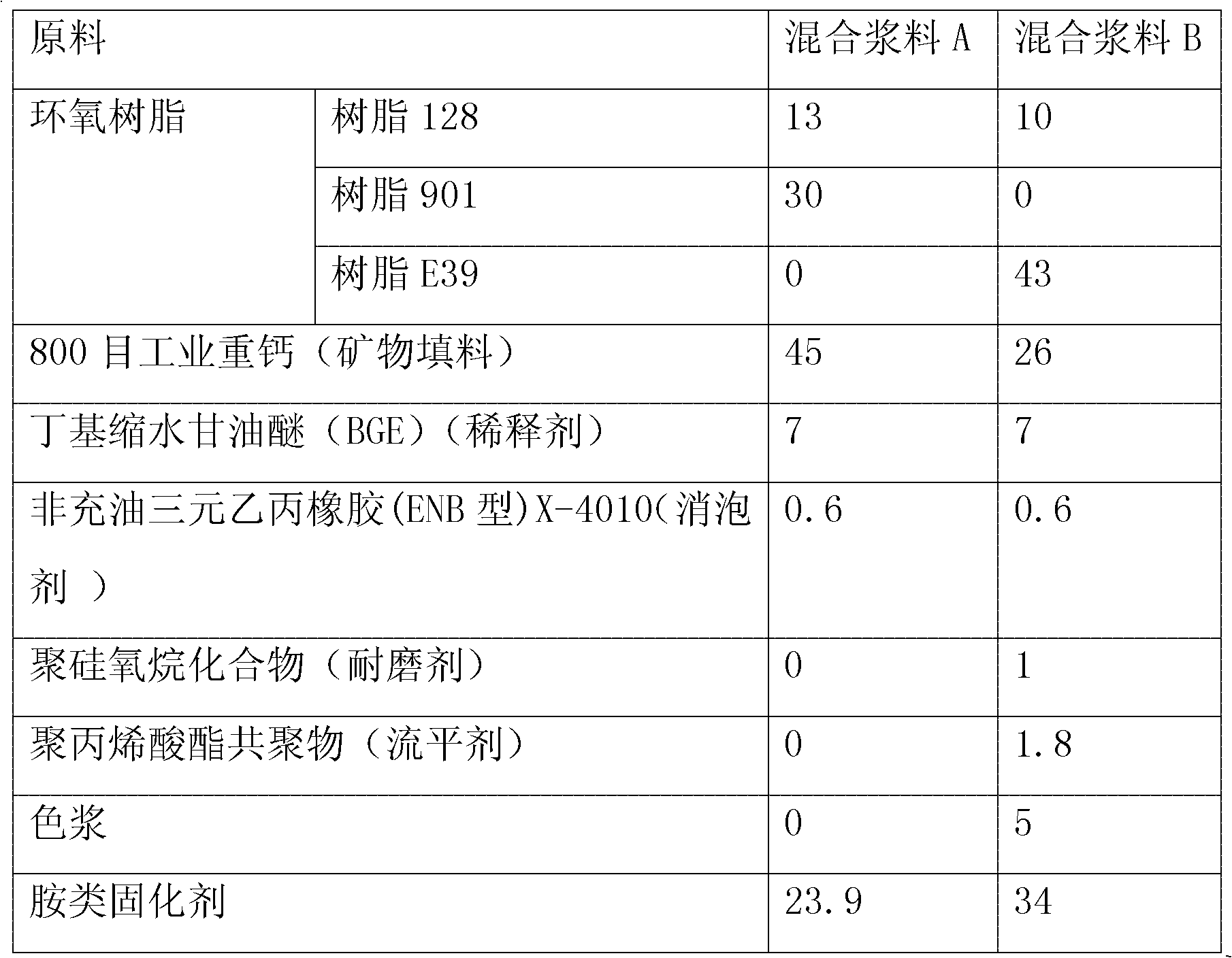

[0024] The formula of table 2 embodiment 2 (unit: weight part)

[0025]

[0026] First, mix all raw materials according to the formula described in Table 2 to prepare one part each of mixed slurry A and mixed slurry B, and use a horizontal coating machine to uniformly coat mixed slurry A with a thickness of 0.25mm on wet PU coating Cloth (thickness 0.6mm, modulus 350) and warp-knitted woven glass fiber cloth (when glass fiber sizing, the weft yarn is sizing with silane type size, the warp yarn is sizing with starch type size, and the weaving density is 30 warp yarns / 10cm , 50 weft yarns / 10cm) compositely sent into an oven with a gradient temperature of 80-115°C for baking, with a temperature gradient of 8°C, baked for 2 minutes at each temperature gradient, and polished the surface of the warp-knitted glass fiber cloth For dust removal and grinding, 80-200 mesh industrial dry sandpaper is used to wrap the grinding roller, and the grinding roller rotates in reverse at a spee...

Embodiment 3

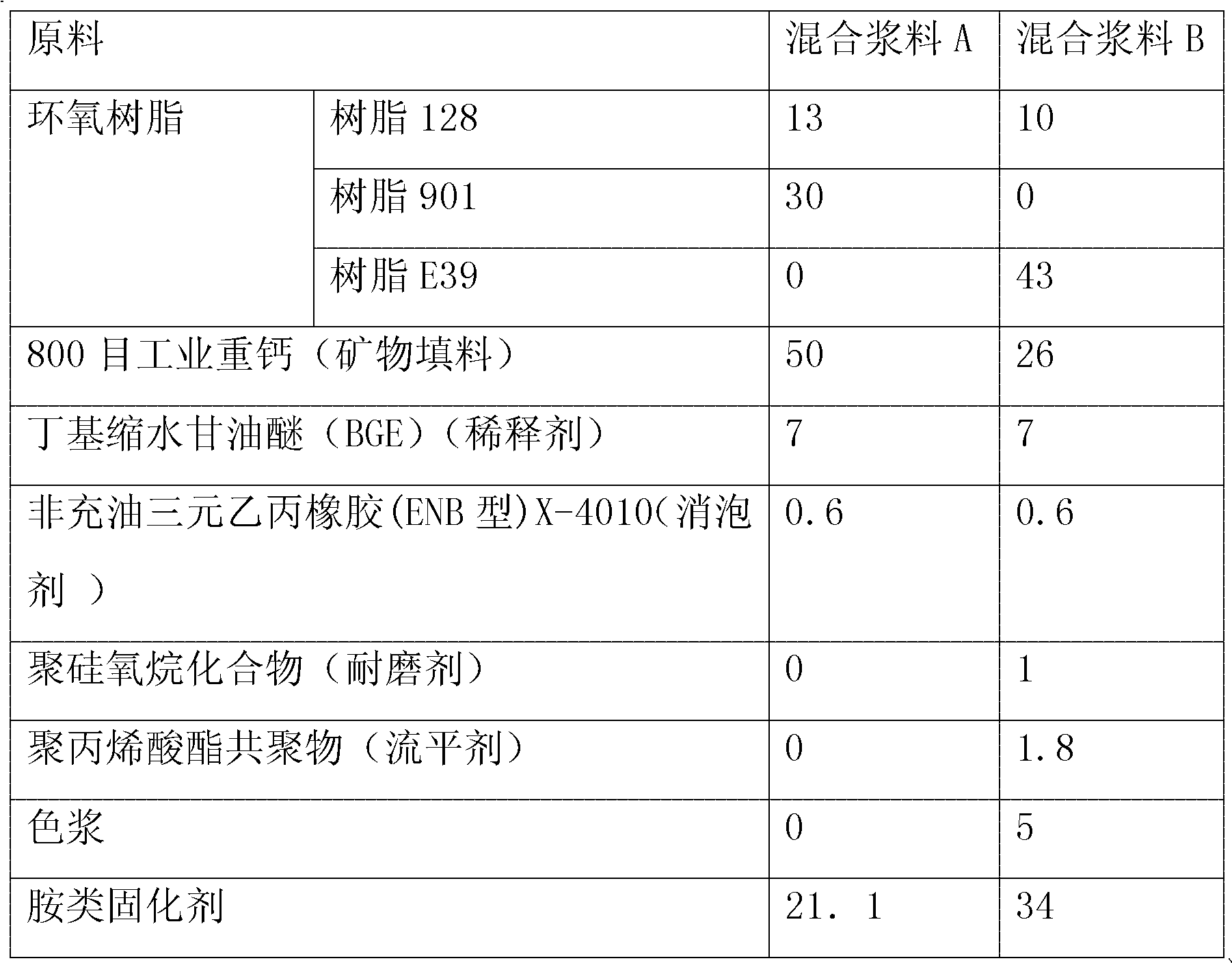

[0028] The formula of table 3 embodiment 3 (unit: weight part)

[0029]

[0030] First mix all raw materials according to the formula described in table 3 and prepare each part of mixed slurry A and mixed slurry B respectively, utilize horizontal coating machine to evenly coat mixed slurry A on the PVC light box cloth with a thickness of 0.25mm ( The thickness is 0.5mm, the hardness is 35D Zhao's hardness, the water-based PU layer thickness on the PVC light box cloth is 0.05mm) and warp-knitted woven glass fiber cloth (when glass fiber sizing, the weft yarn is sizing with silane type size, and the warp yarn is sizing with starch type size sizing yarn, the weaving density is 38 warp yarns / 10cm, and weft yarn 48 yarns / 10cm) compositely sent to 80-115°C oven with gradient temperature for baking, the temperature gradient is 7°C, and baked under each temperature gradient In 2.2 minutes, the surface of the warp-knitted glass fiber cloth is polished and dust-removed, and the grind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com