System and method for removing impurity from liquor

A wine liquid and wine pump technology, which is applied in the field of wine preparation, can solve the problems of shortening the storage time of wine and the selective adsorption of difficult odors, and achieve the effects of shortening the natural storage period, reducing the loss of beneficial gases, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

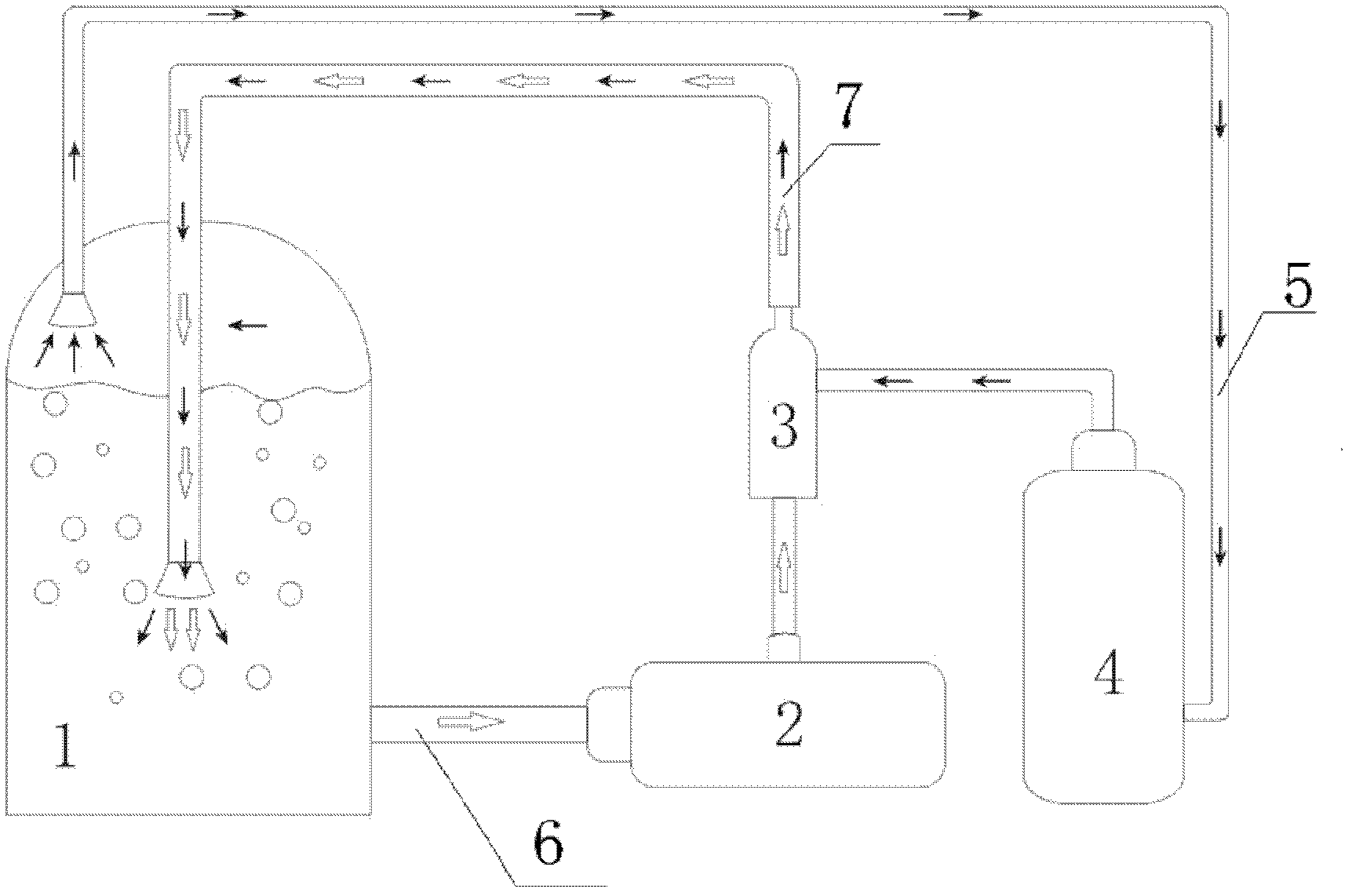

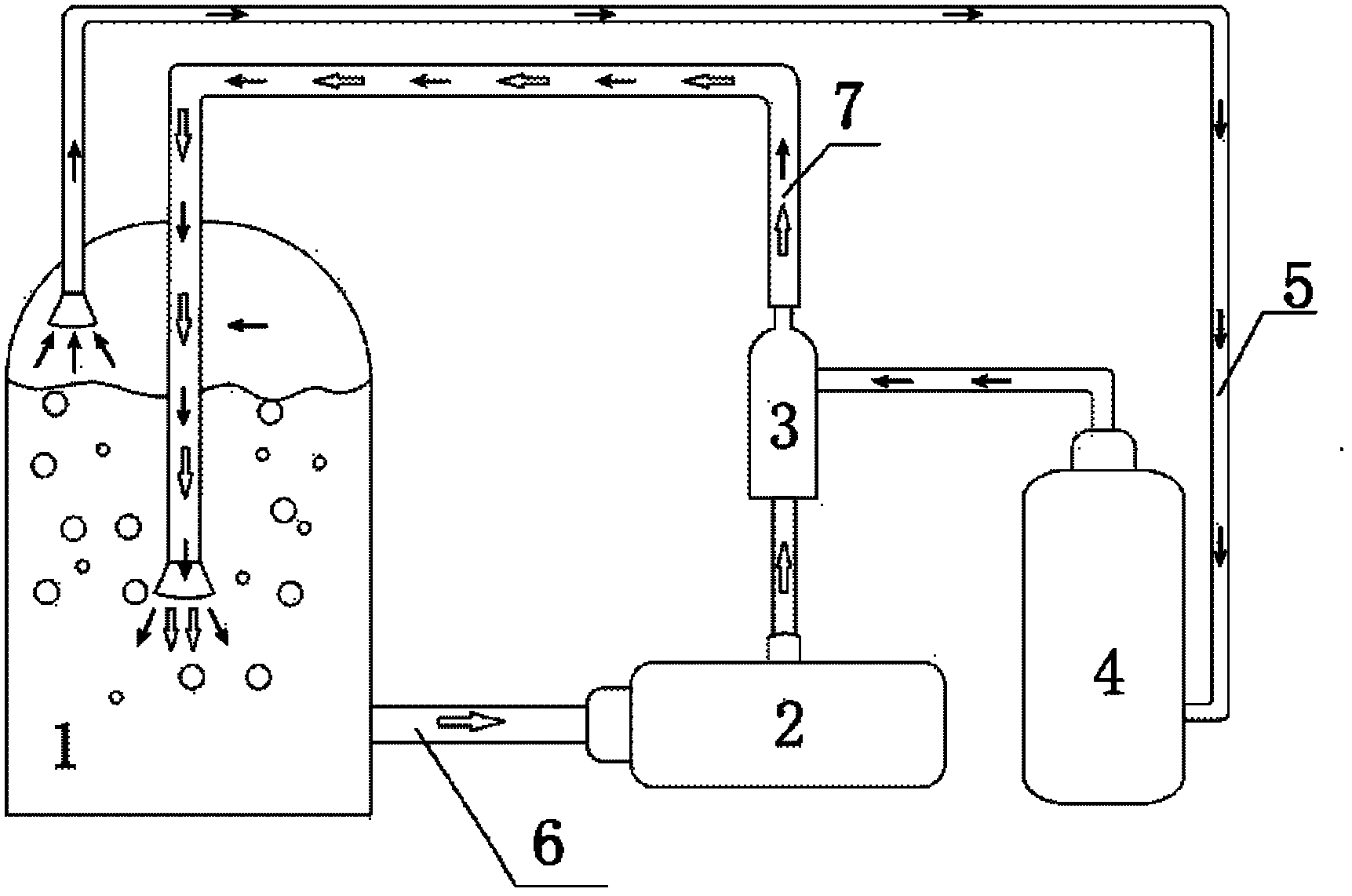

[0019] refer to figure 1 , The wine liquid impurity removal system of the present invention is mainly composed of a wine liquid storage tank 1, a wine pump 2, a vapor adsorption separation tank 4, a vapor-liquid mixer 3 and connecting pipes. Among them, the wine pump 2 uses a stainless steel pump with a flow rate of 50T / h and a head of 25 meters; the vapor-liquid mixer 3 uses a stainless steel venturi jet that matches the parameters of the wine pump, and is provided with two input ports a and b And an output port c, when the wine liquid flows through the Venturi jet, the negative pressure generated by it and the positive pressure output by it are used to form an air circulation system in the closed system. The gas adsorption and separation tank 4 adopts a stainless steel tank body, and an adsorption material is housed in the tank. The adsorption material is selected from biological fermentation liquid or active carbon or resin with adsorption performance. Harmful substances i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com