Construction method for hollow thin-walled high pier non-bracket formwork turnover of railway

A hollow thin-walled, construction method technology, applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., can solve the problems of lack of safety guarantee, increase of construction cost, complicated operation, etc., to save materials and labor, simplify formwork structure, The effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

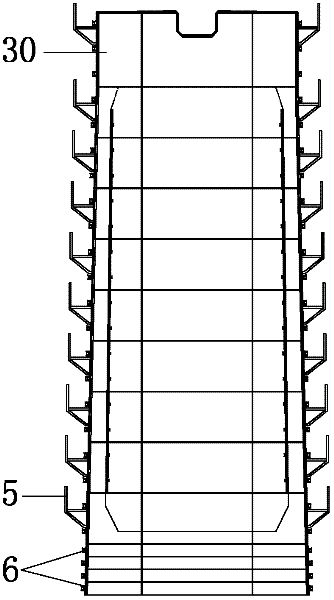

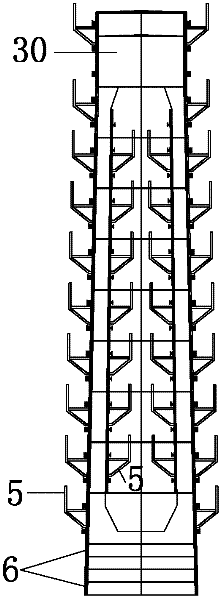

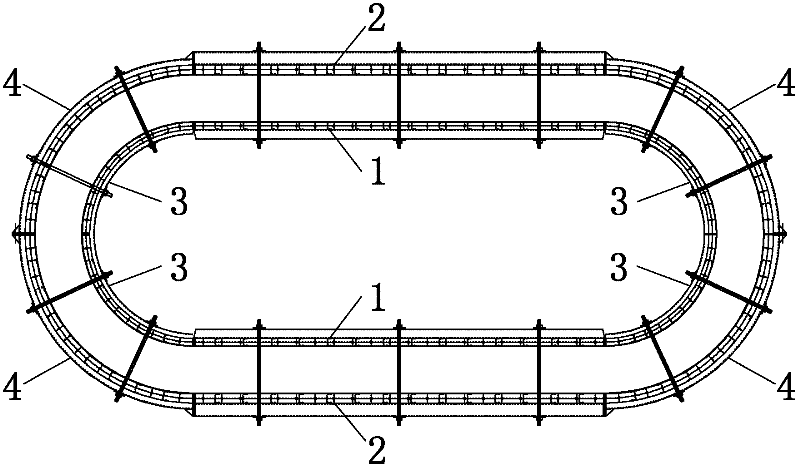

[0046] The construction method of the hollow thin-walled high pier without support of the present invention will be described in conjunction with the accompanying drawings and examples.

[0047] The construction method of the hollow thin-walled high pier of the present invention without support and overturning the formwork, the overall construction sequence of the method is the construction of the first section solid section construction, the middle section construction, and the pier cap construction; the formwork adopts shaped steel formwork, and the pier body The steel bars and formwork are vertically lifted by the crane according to the terrain and pier height conditions, and the construction concrete is pumped by the automobile pump. The construction personnel go up and down the pedestrian stairway built outside the hollow pier and inside the hollow pier:

[0048] (1) Template structure

[0049] figure 1 , figure 2 Hollow thin-walled high pier without support formwork a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com