Direct expansion type mine return air source heat pump system and operation method thereof

A mine return air, expansion technology, applied in heat pumps, lighting and heating equipment, refrigeration components, etc., can solve problems such as energy loss, complex process, etc., to reduce the area, improve the utilization rate, and reduce the volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

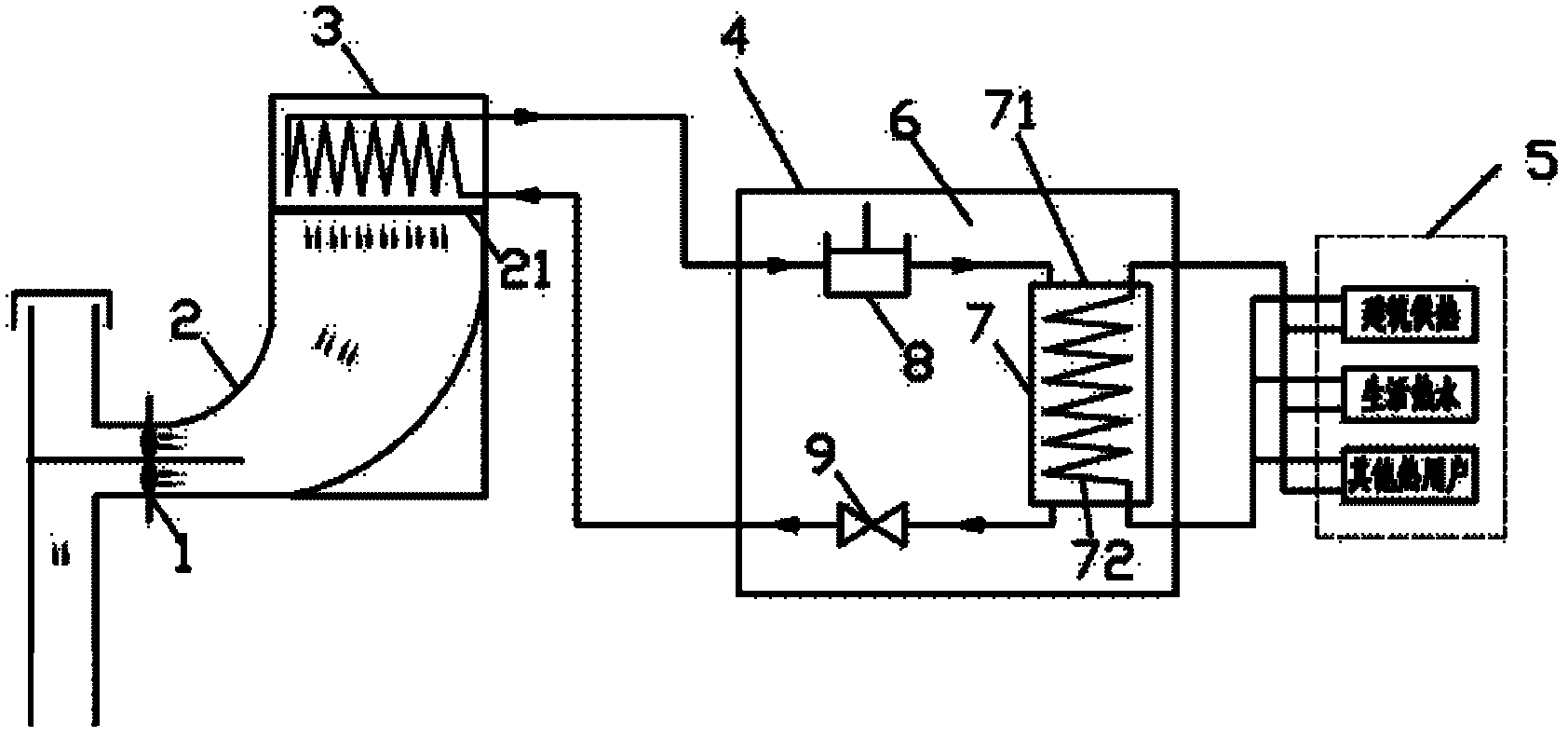

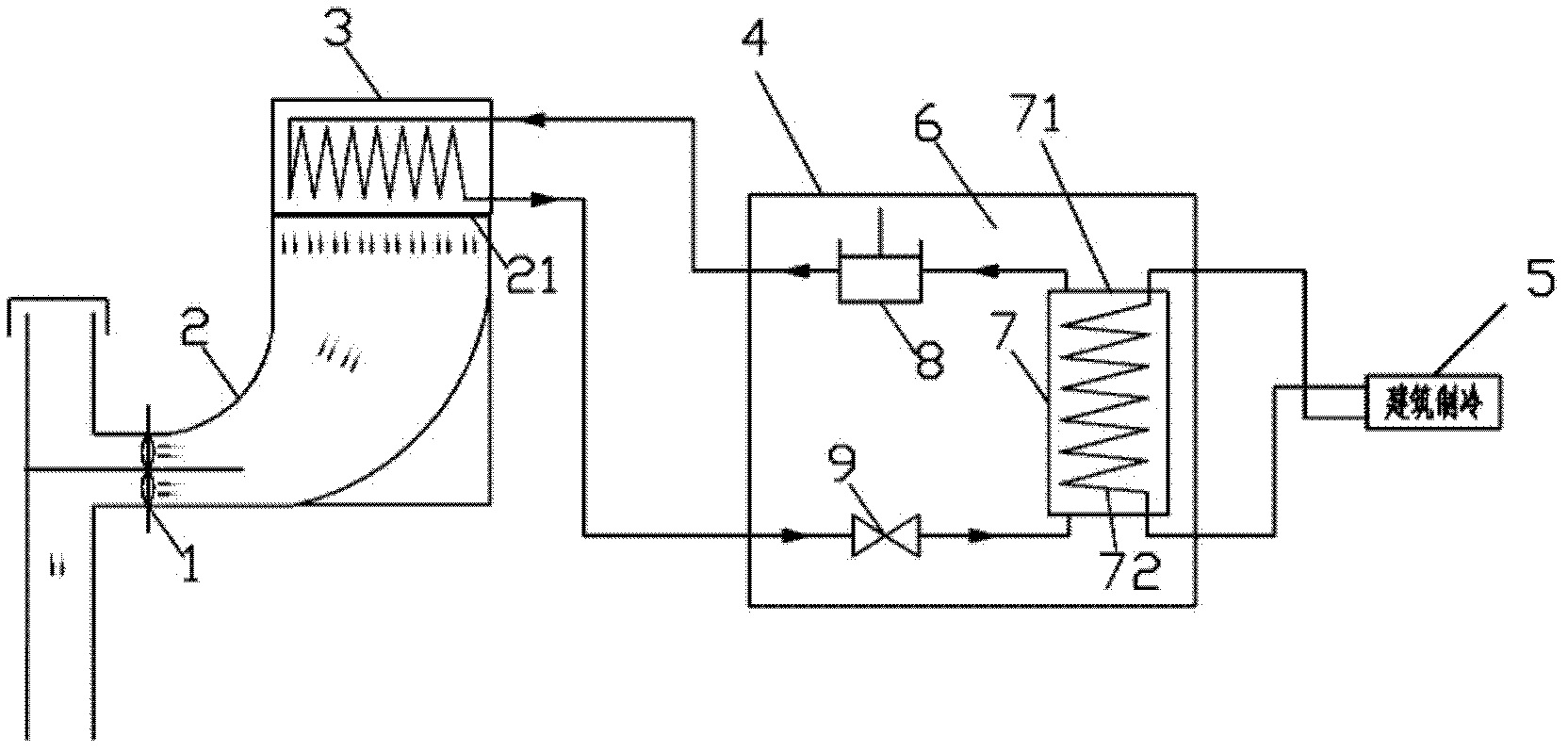

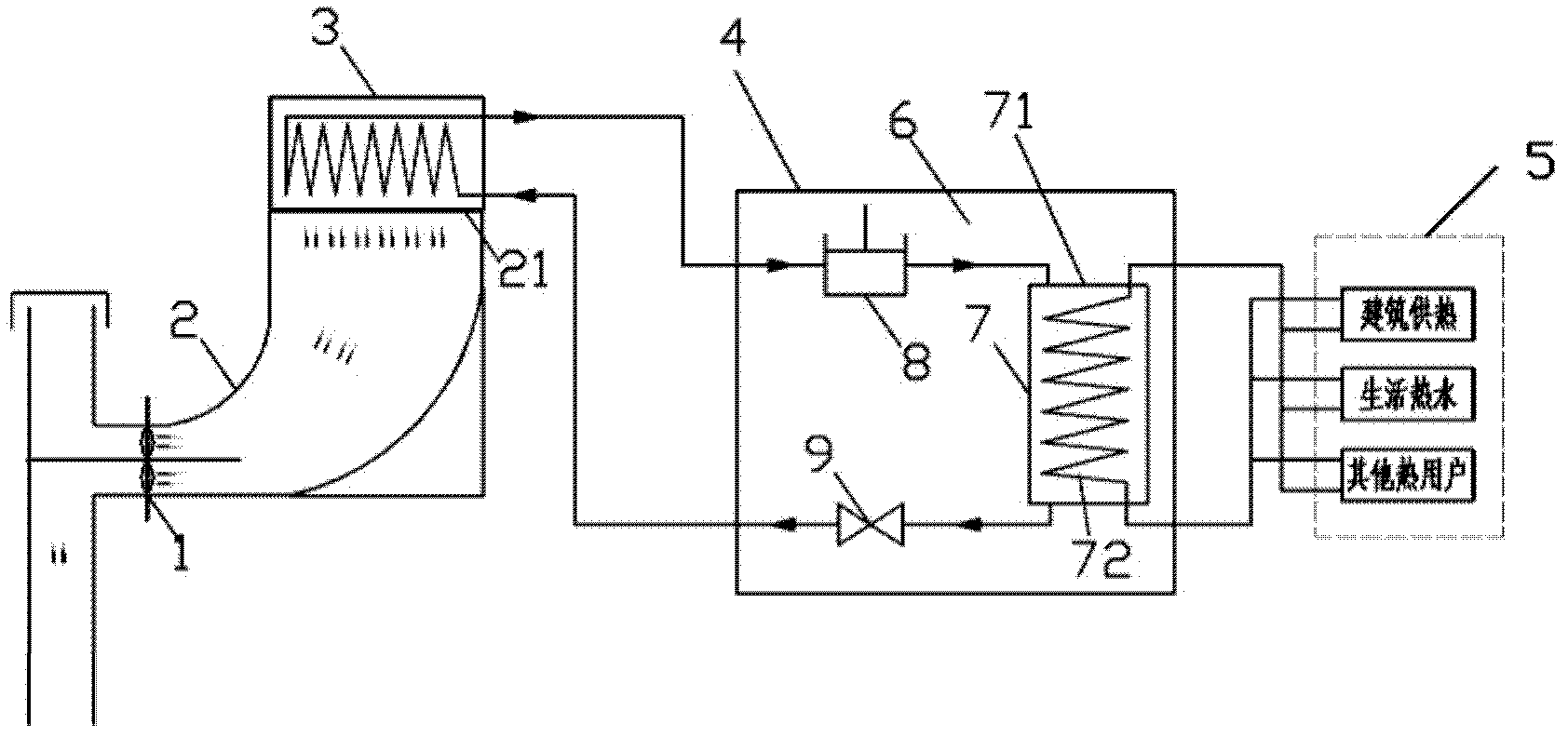

[0020] Such as figure 1 As shown, the system of the present invention includes a diffusion tower 2 arranged at the outlet 1 of the mine return air source, an external air-liquid heat exchanger 3 , a heat pump unit 4 and a user equipment unit 5 . An air outlet 21 is arranged on the top of the diffusion tower 2, and an external air-liquid heat exchanger 3 is arranged on the top of the air outlet 21, and the external air-liquid heat exchanger 3 is filled with refrigerant. According to the heat exchange capacity of the external air-liquid heat exchanger 3, the heat pump unit 4 can be composed of one or more parallel heat pump units 6, one group is taken as an example in the figure. Each heat pump unit 6 includes a built-in heat exchanger 7 , a compressor 8 with a reversing valve and an expansion valve 9 . The external gas-liquid heat exchanger 3 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com