Process for preparing high-pressure medical oxygen

A high-pressure oxygen and high-pressure technology, applied in the field of high-pressure medical oxygen production technology, can solve the problems of large maintenance workload, high maintenance cost, large floor space, etc., and achieve the effects of less danger, lower energy consumption requirements, and avoidance of pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

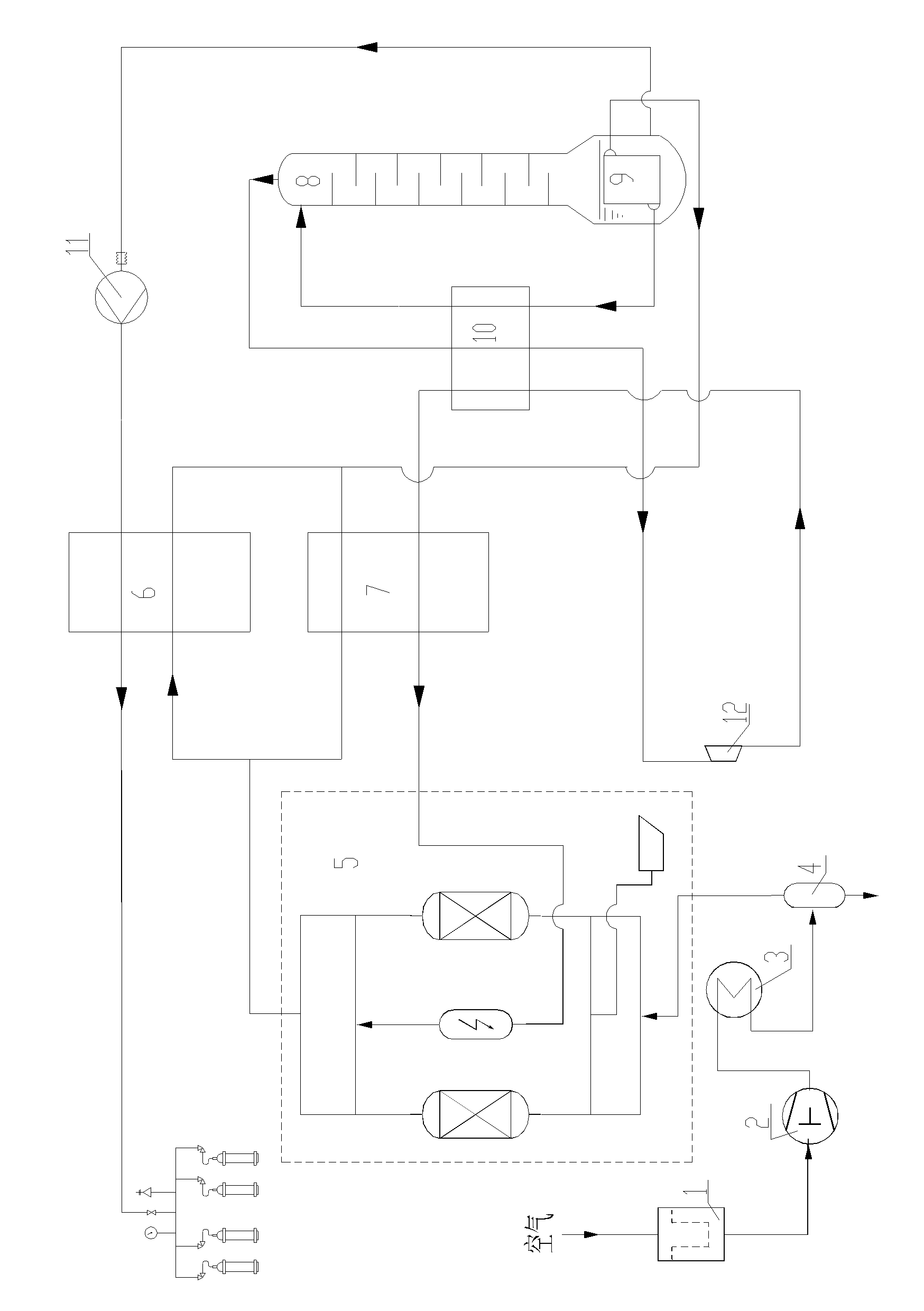

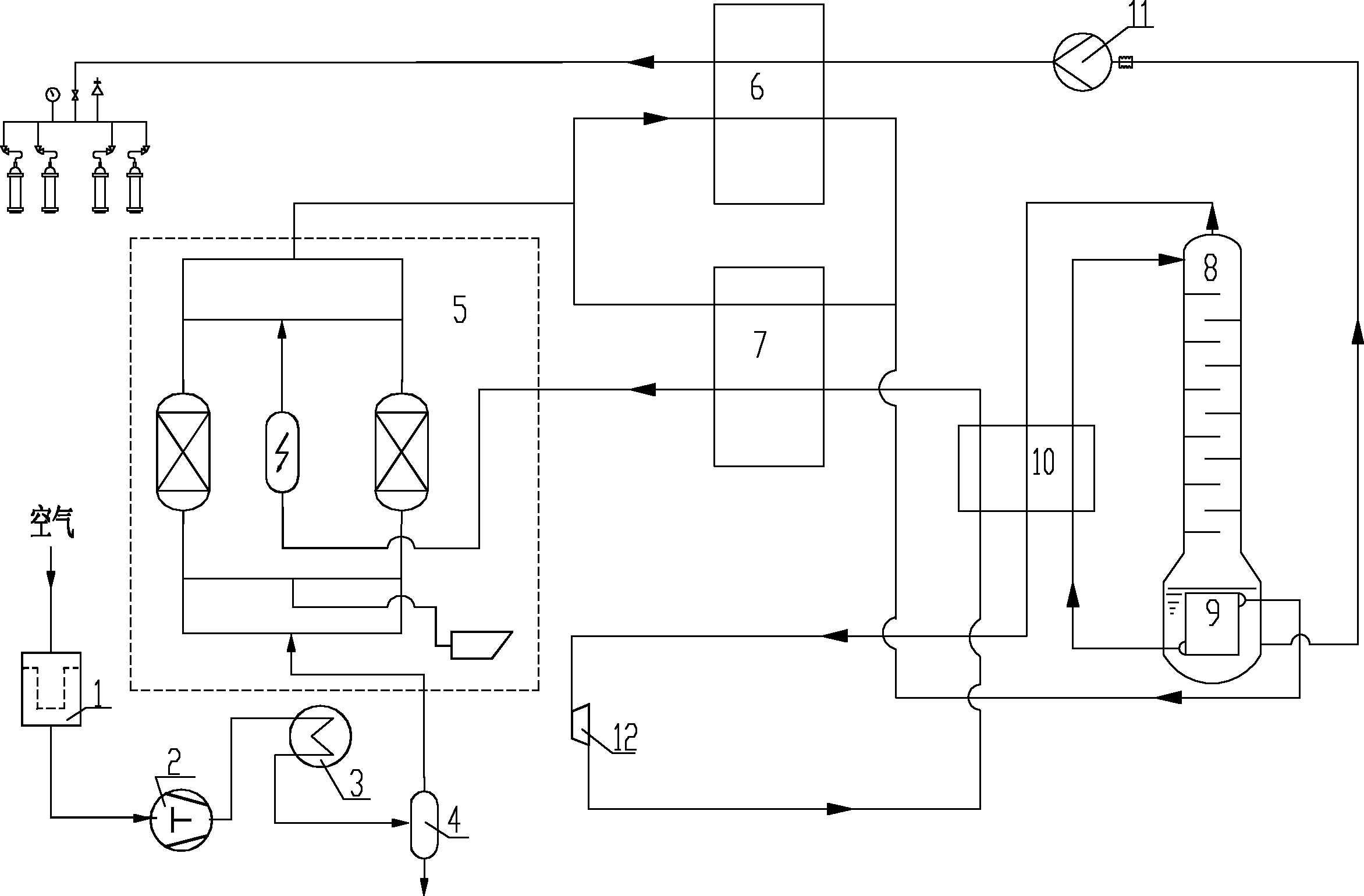

[0012] Preparation of high-pressure medical oxygen products requires a pressure of 15Mpa: see figure 1 , the raw air passes through the air filter 1 to remove dust and impurities in the air, and then is compressed to 1.2MPa by the air compressor 2, then the air temperature is lowered by the air-conditioning unit 3, enters the water separator 4 to separate free water, and then enters the purification system 5. Remove H 2 O.CO 2 、C 2 h 2 and other hydrocarbons, the purified air is divided into two paths: one path enters the high-pressure oxygen coil heat exchanger 6, and exchanges heat with supercritical liquid oxygen, and the purified air is condensed while the liquid oxygen is vaporized into normal temperature and high pressure oxygen It is a saturated liquid; the other path passes through the main heat exchanger 7 to exchange heat with the expanded waste gas and cools to the saturation temperature; these two paths of saturated liquid and air merge and then enter the conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com