Method and device for evaluating aroma loss of air flow drying procedure

A technology for air drying and aroma, applied in the field of cigarette manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

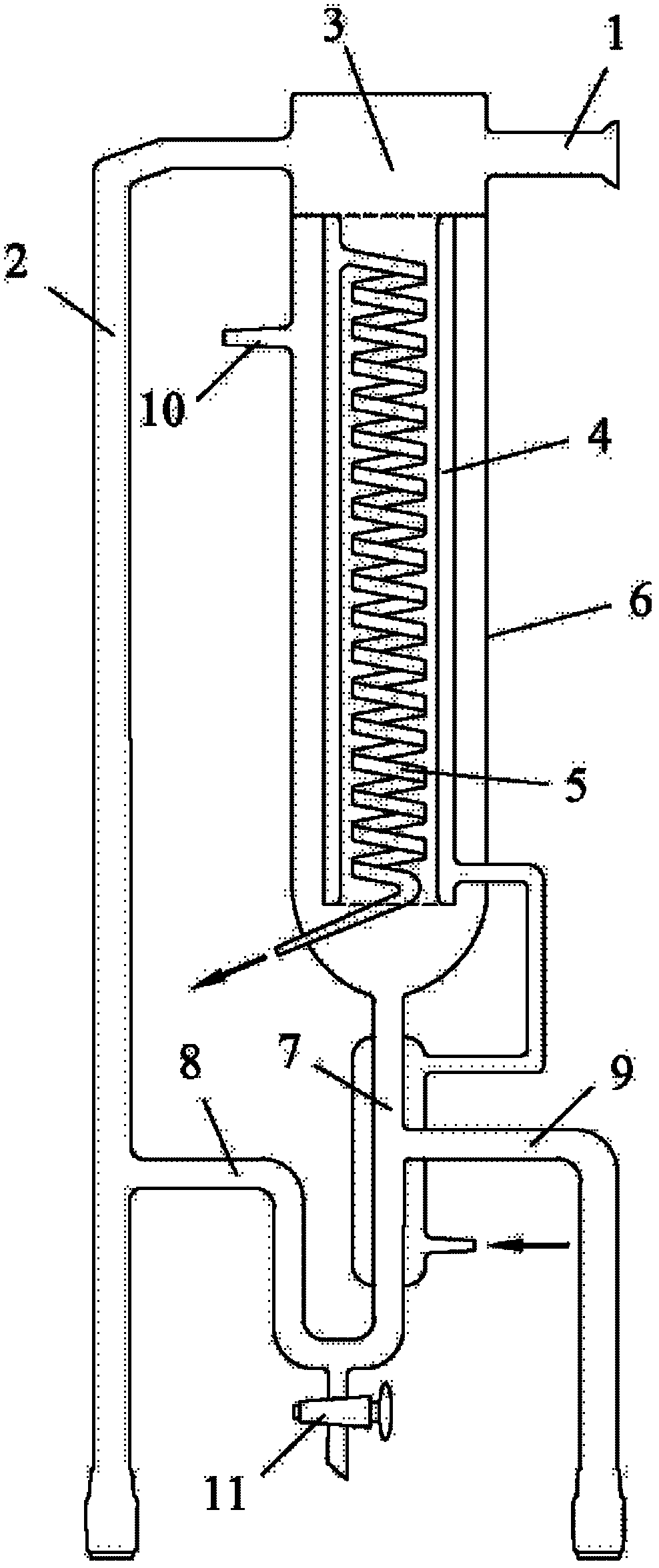

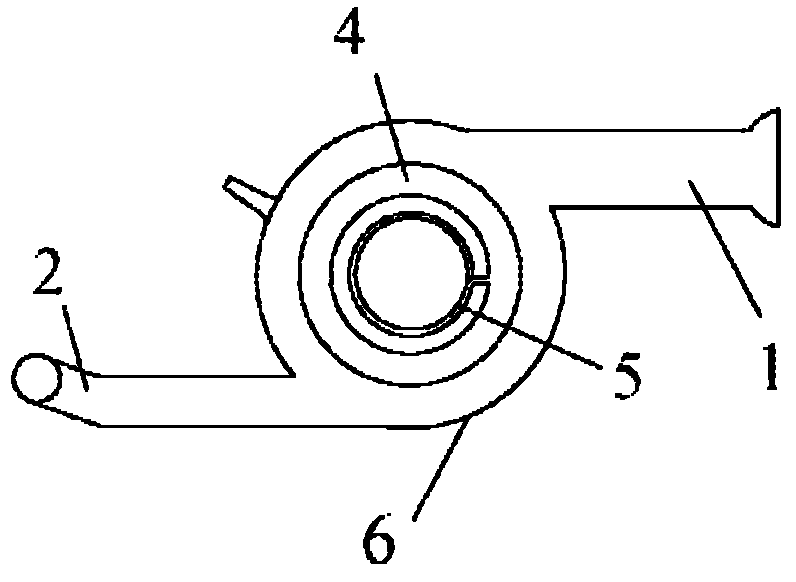

[0081] An Apparatus for Evaluating Aroma Loss in Airflow Drying Equipment Process - Simultaneous Trapping Extractors, such as figure 1 and figure 2 shown, including:

[0082] The steam introduction pipe (1), the steam introduction pipe (1), the organic solvent vapor conduit (2), and the steam-gas two-phase mixing chamber (3) are arranged in dislocation on the same horizontal plane, and placed parallel to the upper end of the condensation extraction chamber; The extraction chamber is composed of a cylindrical condensation surface (4), a serpentine condensation pipe (5) placed therein, and an outer wall layer (6), and the outer wall layer (6) is provided with a pressure balance port (10); the condensation extraction chamber Connected to the liquid-liquid two-phase extraction pipe 7; the liquid-liquid two-phase extraction pipe (7) is also connected to the organic phase outlet pipe (8) and the aqueous phase outlet pipe (9), and the discharge valve (11).

[0083] The outer diame...

Embodiment 2

[0085] An Apparatus for Evaluating Aroma Loss in Airflow Drying Equipment Process - Simultaneous Trapping Extractors, such as figure 1 and figure 2 shown, including:

[0086] The steam introduction pipe (1), the steam introduction pipe (1), the organic solvent vapor conduit (2), and the steam-gas two-phase mixing chamber (3) are arranged in dislocation on the same horizontal plane, and placed parallel to the upper end of the condensation extraction chamber; The extraction chamber is composed of a cylindrical condensation surface (4), a serpentine condensation pipe (5) placed therein, and an outer wall layer (6), and the outer wall layer (6) is provided with a pressure balance port (10); the condensation extraction chamber Connected to the liquid-liquid two-phase extraction pipe 7; the liquid-liquid two-phase extraction pipe (7) is also connected to the organic phase outlet pipe (8) and the aqueous phase outlet pipe (9), and the discharge valve (11).

[0087] The outer diamete...

Embodiment 3

[0089] A method for evaluating aroma loss in airflow drying equipment process, including:

[0090] 1) Install a galvanized steel pipe with an inner diameter of 20mm on the moisture exhaust steam pipeline about 3 meters behind the moisture exhaust damper of the airflow drying equipment (HXD of Dicksin-Legg, UK, the same below) to control the steam flow; Connect with a glass tube with a suitable diameter and length according to local conditions and a suitable interface, and introduce steam into the steam introduction pipe 1 (spherical interface) of the simultaneous trapping and extracting instrument (the simultaneous trapping and extracting instrument of Example 1 is used in this embodiment);

[0091] 2) At the same time, a glass container with a certain volume is connected to the aqueous phase outlet pipe 9 of the trapping extractor;

[0092] 3) Connect the flat-bottomed flask to the organic phase outlet tube 8 of the simultaneous trapping and extraction instrument, add 60mL of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com