Automatic heating and aerating device of sulfur hexafluoride cylinder

An automatic heating and inflation device technology, applied in the direction of switchgear, electrical components, etc., can solve problems such as uneven heating, waste, and potential safety hazards, and achieve the effects of improving gas utilization, reducing residual volume, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

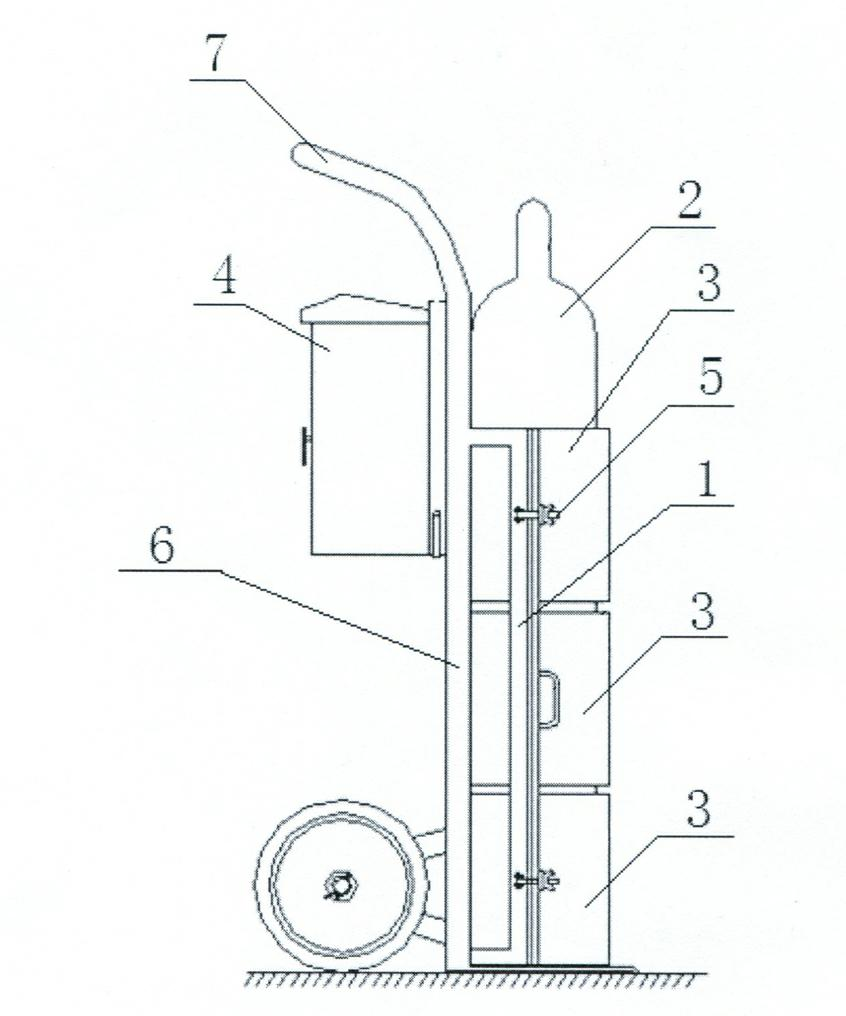

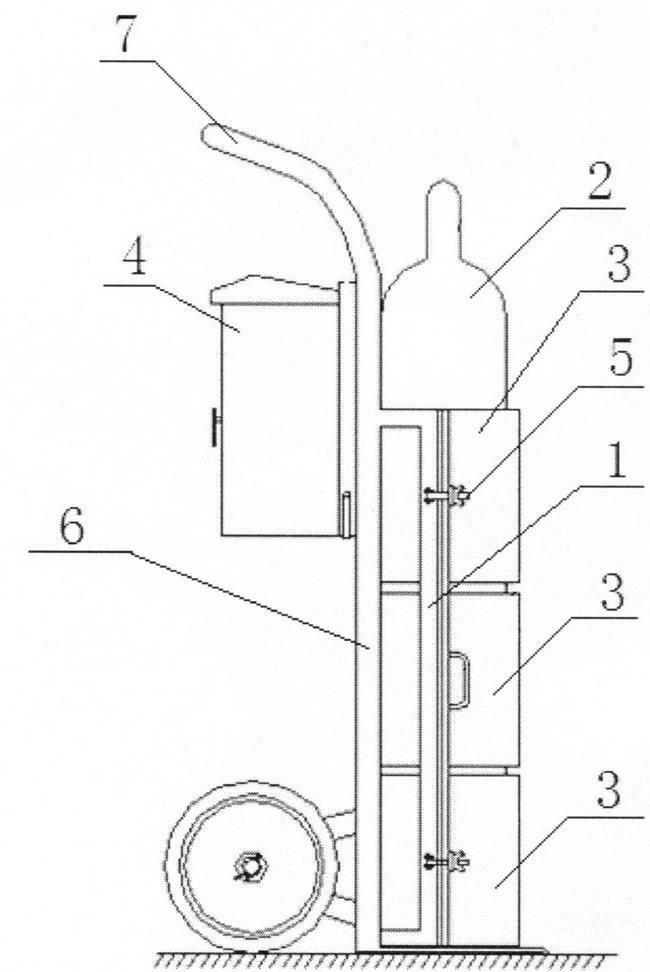

[0012] like figure 1 As shown, a sulfur hexafluoride gas cylinder automatic heating and filling device includes a trolley, a gas cylinder 2, a coil heater 3, and a control cabinet 4; Tighten the bolts and nuts 5 to fix several coil heaters 3, the inner diameter of the coil heaters 3 is slightly larger than the outer diameter of the gas cylinder 2; the gas cylinder 2 is inserted into the coil heater 3 and fixed on the trolley Above the platform 6, the control cabinet 4 is installed under the trolley platform 6 and close to one end of the trolley handle 7.

[0013] Instructions:

[0014] When the automatic heating and filling device for sulfur hexafluoride gas cylinders of the present invention is in use, the gas cylinder 2 is inserted into the coil heater 3, the trolley is pushed or pulled to the operating place, the power is turned on, and the temperature upper limit is selected on the control panel. Press the heating button. When the temperature reaches the required tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com